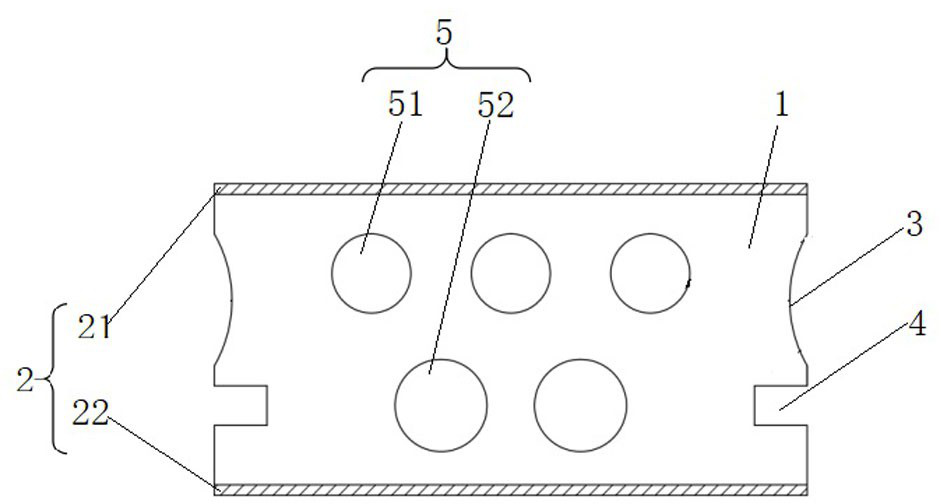

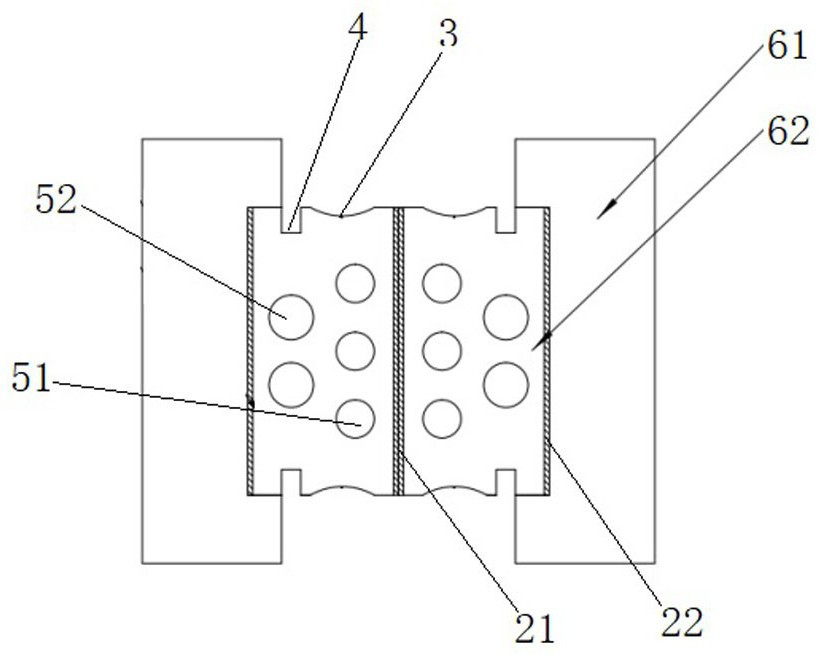

Self-adhesive elastic sealing gasket and formed butt joint structure of shield segments

A technology of elastic sealing gasket and shield segment, applied in the direction of adhesive, adhesive type, oil/grease/wax adhesive, etc., can solve problems such as affecting the normal use of tunnel engineering, leakage of water, shortening of service life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

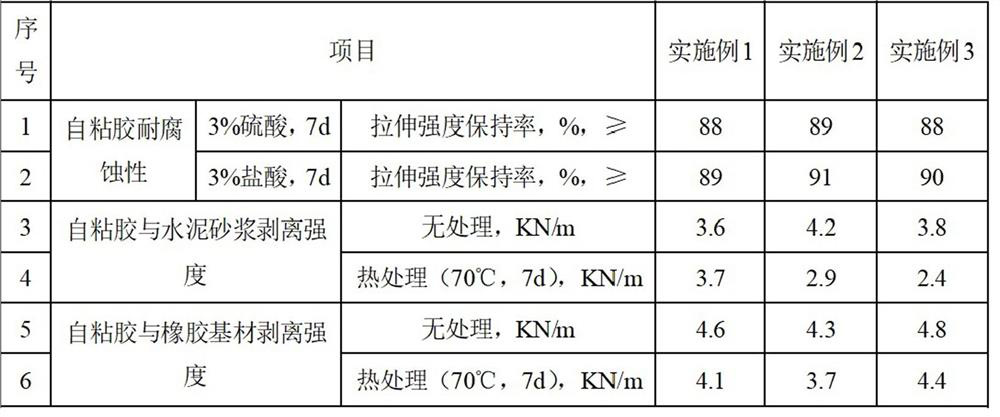

Examples

Embodiment 1

[0047] Reactor temperature rises to 170 ℃, with 22 parts by weight of modified thermoplastic elastomer SBS, 22 parts by weight of modified thermoplastic elastomer SIS, 11 parts by weight of plasticizer naphthenic oil, 44 parts by weight of C5 hydrogenated petroleum resin, 0.3 parts by weight 3 parts by weight of organic ultraviolet absorber UV-531 and 3 parts by weight of inorganic anti-ultraviolet agent rutile titanium dioxide, 3 parts by weight of polyisobutylene-maleic anhydride copolymer are added to the reactor, and the reactor speed is 45 rpm, and Fill with nitrogen protection, stir for 220 minutes, discharge the self-adhesive, cool, and pack for use.

[0048] Mix 60 parts by weight of natural rubber with 40 parts by weight of butadiene rubber in an internal mixer, then add 4 parts of zinc oxide, 2 parts of stearic acid, 2 parts of antioxidant RD, and 0.3 parts of rubber antifungal agent OBPA After mixing for 40 seconds, add 40 parts of reinforcing agent N330, 5 parts of...

Embodiment 2

[0051] Reactor temperature rises to 180 ℃, with 24 parts by weight of modified thermoplastic elastomer SBS, 24 parts by weight of modified thermoplastic elastomer SIS, 13 parts by weight of plasticizer naphthenic oil, 46 parts by weight of C5 hydrogenated petroleum resin, 0.4 parts by weight Part organic ultraviolet absorber UV-531 and 4 parts by weight of inorganic anti-ultraviolet agent rutile type titanium dioxide, 4 parts by weight of polyisobutylene-maleic anhydride copolymer are added in the reactor, the rotating speed is 60 rev / min, and nitrogen gas Protect, stir for 240 minutes, discharge the self-adhesive, cool, and pack for use.

[0052] In the internal mixer, 70 parts of natural rubber was masticated and mixed with 30 parts by weight of styrene-butadiene rubber, and then 5 parts by weight of zinc oxide, 3 parts by weight of stearic acid, 2.5 parts of anti-aging agent 4010NA, 0.4 parts by weight of rubber anti-aging agent were added. Mold agent pentachlorophenol, aft...

Embodiment 3

[0055] Reactor temperature rises to 180 ℃, with 25 parts by weight of modified SBS, 25 parts by weight of modified SIS, 15 parts by weight of plasticizer naphthenic oil, 50 parts by weight of C5 hydrogenated petroleum resin, 0.5 parts by weight of organic ultraviolet absorber Add UV-531, 4 parts by weight of inorganic anti-ultraviolet agent rutile titanium dioxide, and 5 parts by weight of silane coupling agent into the reaction kettle at a speed of 55 rpm, and fill it with nitrogen protection, stir for 260 minutes, and put the self-adhesive Drain, cool, and pack for use.

[0056] In the internal mixer, 75 parts by weight of natural rubber was masticated and mixed with 25 parts of butadiene rubber, and then 5 parts by weight of zinc oxide, 2.5 parts by weight of stearic acid, 3 parts by weight of antioxidant 4010NA, and 0.6 parts by weight of rubber Antifungal agent 8-hydroxyquinolinone, after mixing for 35 seconds, add 50 parts by weight of reinforcing agent N550, 8 parts by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com