Cobalt disulfide/sulfide solid electrolyte composite positive electrode material coated with carbon nanotubes, and preparation method and application thereof

A technology of composite cathode material and solid electrolyte, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of interface compatibility and stability affecting the performance of all-solid-state batteries, battery capacity decay, and interface resistance increase. Achieve uniform size, high stability and good interface compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

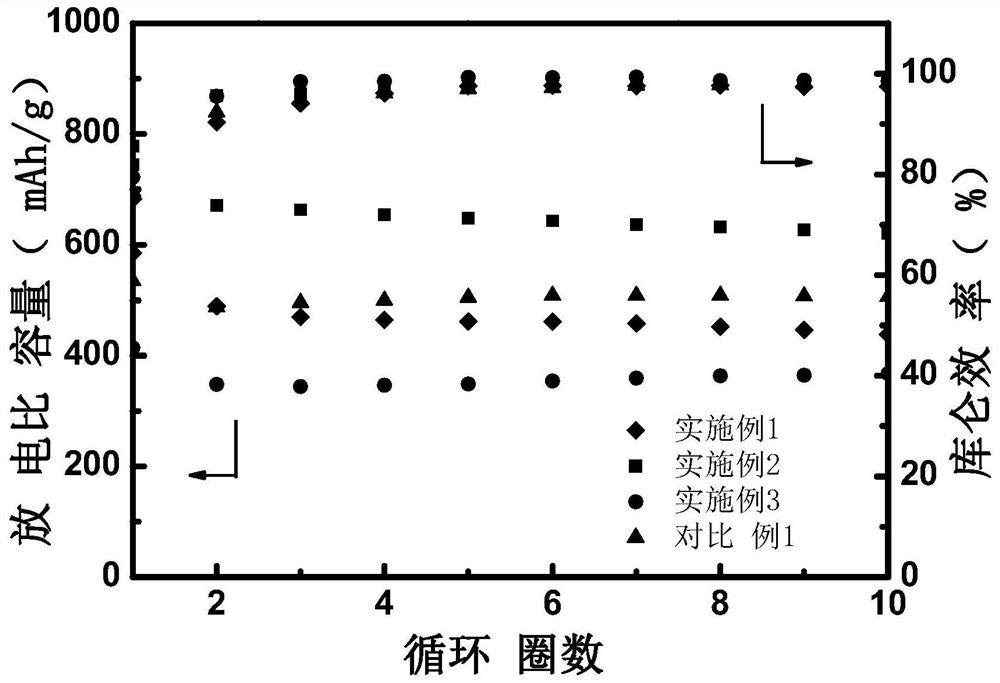

Embodiment 1

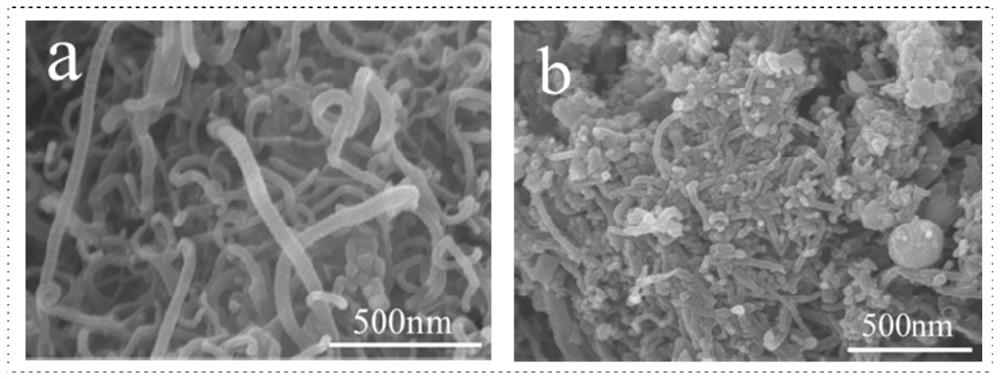

[0042] The preparation of carbon nanotube-coated cobalt disulfide / sulfide solid electrolyte composite positive electrode material, the specific steps are:

[0043] (1) Weigh 0.4g of cobalt nitrate hexahydrate, 0.05g of anhydrous glucose, and 4g of melamine, add the three drugs into 80mL of deionized water, ultrasonicate for 10 minutes, stir magnetically at 80 degrees for 2 hours, and finally transfer to an oven Medium dry.

[0044] (2) Transfer the dry powder to the magnetic boat, and then place the magnetic boat in an argon-protected tube furnace for high-temperature carbonization at 800 °C, with a heating rate of 2 °C / min, keep warm for two hours, and naturally cool to room temperature to obtain carbonization after the material.

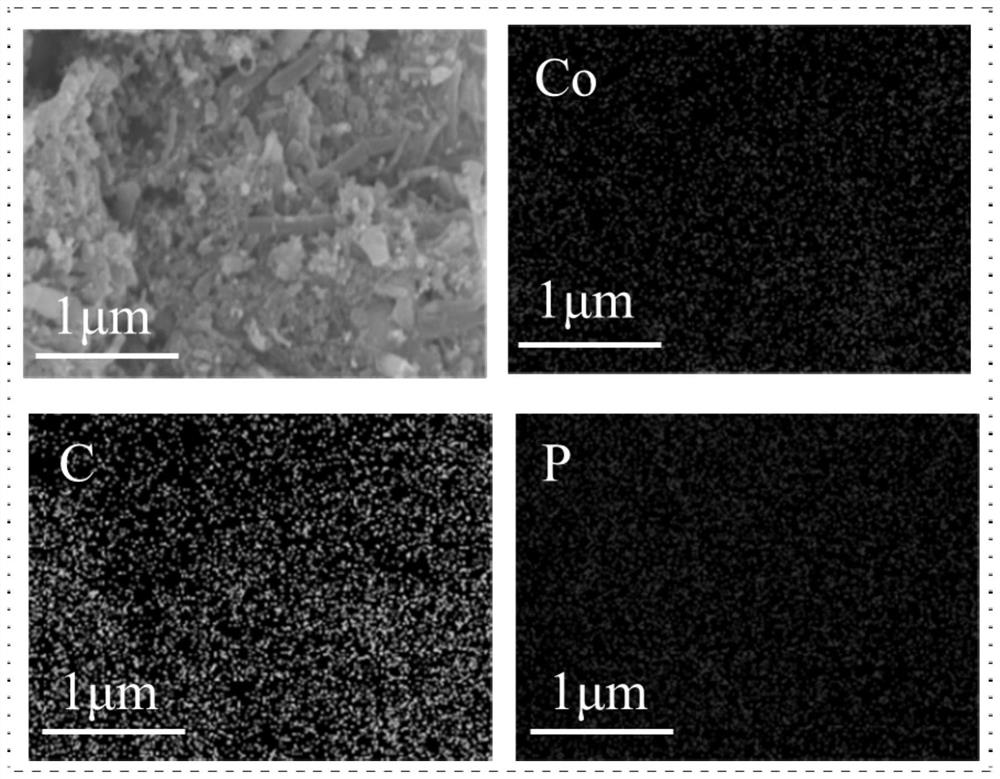

[0045] (3) Weigh 50 mg of the material obtained in step (2) and 5 g of thiourea and spread them in two different magnetic boats, and then place the two magnetic boats in the middle of an argon-protected tube furnace. Carry out vulcanization, heat...

Embodiment 2

[0048] The preparation of carbon nanotube-coated cobalt disulfide / sulfide solid electrolyte composite positive electrode material, the specific steps are:

[0049](1) Weigh 0.4g of cobalt nitrate hexahydrate, 0.05g of anhydrous glucose, and 4g of melamine, add the three drugs into 80mL of deionized water, ultrasonicate for 10 minutes, stir magnetically at 80 degrees for 2 hours, and finally transfer to an oven Medium dry.

[0050] (2) Transfer the dried powder to a magnetic boat, and then place the magnetic boat in an argon-protected tube furnace for high-temperature carbonization at 800°C, with a heating rate of 2°C / min, keep it warm for two hours, and naturally cool to room temperature to obtain carbonization after the material.

[0051] (3) Weigh 50 mg of the material obtained in step (2) and 5 g of thiourea and spread them in two different magnetic boats, and then place the two magnetic boats in the middle of an argon-protected tube furnace. Carry out vulcanization, heat...

Embodiment 3

[0056] The preparation of carbon nanotube-coated cobalt disulfide / sulfide solid electrolyte composite positive electrode material, the specific steps are:

[0057] (1) Weigh 0.4g of cobalt nitrate hexahydrate, 0.05g of anhydrous glucose, and 4g of melamine, add the three drugs into 80mL of deionized water, ultrasonicate for 10 minutes, stir magnetically at 80 degrees for 2 hours, and finally transfer to an oven Medium dry.

[0058] (2) Transfer the dried powder to a magnetic boat, and then place the magnetic boat in an argon-protected tube furnace for high-temperature carbonization at 800°C, with a heating rate of 2°C / min, keep it warm for two hours, and naturally cool to room temperature to obtain carbonization after the material.

[0059] (3) Weigh 50 mg of the material obtained in step (2) and 5 g of thiourea and spread them in two different magnetic boats, and then place the two magnetic boats in the middle of an argon-protected tube furnace. Carry out vulcanization, hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com