Solid oxide fuel cell, cerium oxide-based isolation layer and preparation method of cerium oxide-based isolation layer

A solid oxide and fuel cell technology, which is applied in the direction of fuel cells, fuel cell parts, metal material coating technology, etc., can solve the problems that do not require catalytic film density, low electrical conductivity, and fuel cell performance degradation, etc. Achieve the effects of improving long-term operation stability, simplifying the preparation process, and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

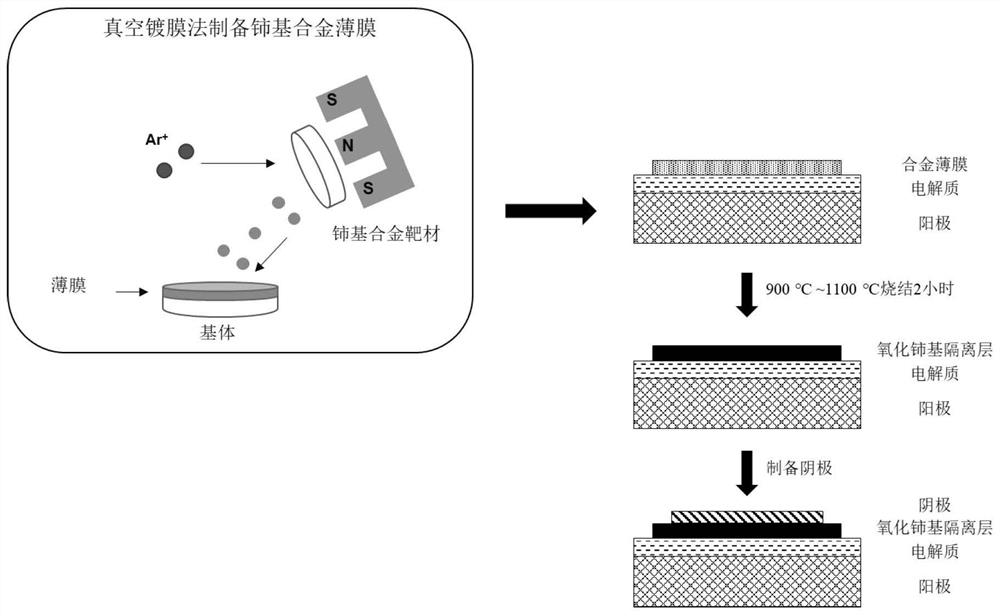

[0050] The invention provides a method for preparing a fuel cell ceria-based isolation layer, comprising:

[0051] Step (1): Using a cerium-based alloy as a target, a cerium-based alloy film is prepared on the surface of an electrolyte layer of a solid oxide fuel cell half-cell by a vacuum coating method, the electrolyte layer is a zirconia-based ceramic film, and the cerium-based The alloy film is an alloy film of cerium and a rare earth element whose valence is trivalent;

[0052] Among them, the molar ratio of cerium and rare earth elements in the cerium-based alloy is determined according to the molar ratio of cerium and rare earth elements in the cerium oxide-based isolation layer; vacuum coating methods include magnetron sputtering, ion coating and other coating technologies.

[0053] Step (2): Sintering the half-cell with the cerium-based alloy thin film obtained in step (1) at 900-1100° C. to form a cerium oxide-based isolation layer on the surface of the electrolyte l...

specific Embodiment

[0085] In each embodiment of the present invention, unless otherwise specified, the raw materials are commercially available products. in:

[0086] Solid oxide fuel cell half-cells were purchased from Xuzhou Huaqing Jingkun Energy Co., Ltd.

[0087] Strontium lanthanum cobalt ferrite (LSCF) powder is ball-milled for 48 hours after mixing the nitrates or oxides corresponding to each metal element according to the stoichiometric ratio, taken out and dried, put into a muffle furnace, and calcined at 1050°C for 5 hours to get.

Embodiment 1

[0089] 1.1. Half-cell with NiO-3YSZ|NiO-8YSZ|YSZ structure:

[0090] The half-cell is provided by Xuzhou Huaqing Jingkun Energy Co., Ltd. The material and thickness of each layer are as follows: the anode support layer of the battery is NiO-3YSZ (NiO:3YSZ mass ratio = 1:1) cermet material, the thickness is 400 μm; the anode of the battery The functional layer is NiO-8YSZ (NiO:8YSZ mass ratio=1:1) cermet material with a thickness of 30 μm; the electrolyte of the battery is 8YSZ with a thickness of 15 μm.

[0091] 1.2. Preparation of isolation layer

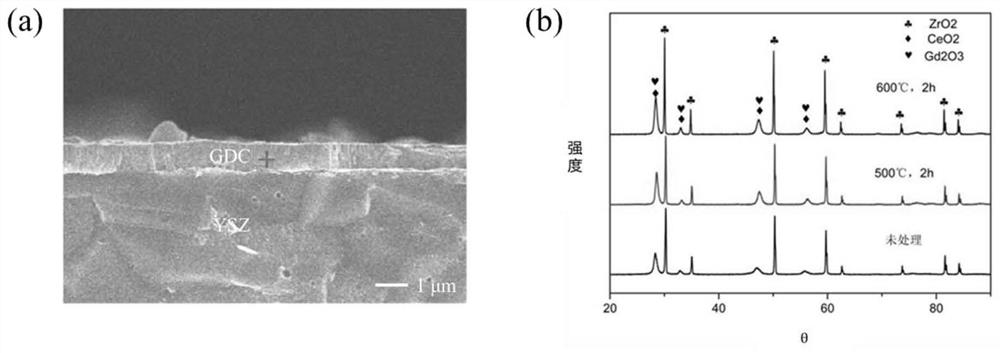

[0092] see figure 1 , on the surface of the electrolyte layer of the half-cell provided in step 1.1, the GDC isolation layer was prepared using the magnetron sputtering method. Ultrasonic cleaning is performed on the sample (ie half-cell) first to remove impurities on the surface of the half-cell. Afterwards, an alloy target composed of metal cerium and gadolinium 9:1 (atomic percentage) was selected, and the half-cell was place...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com