Protein fibers capable of being prepared on large scale and application thereof

A protein fiber, large-scale preparation technology, applied in the direction of single-component protein rayon, cellulose/protein conjugated rayon, fiber treatment, etc., can solve the problems of complex preparation methods, weak mechanical properties, single function, etc. Achieve the effects of simple preparation process, mild conditions and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1. After mixing 1.25g bovine serum albumin, 2mL 500mmol / L tris(2-carboxyethyl)phosphine hydrochloride aqueous solution with pH=5, and 3mL trifluoroethanol, react at 25°C for 30 minutes to generate protein chains Unfolding to obtain a spinning solution.

[0039] 2. Under the driving force of the syringe pump, the spinning solution in step 1 is squeezed into water from the spinneret to obtain primary protein fibers with an amyloid-like structure on a large scale; wherein the diameter of the spinneret is 0.21 mm, and the setting The extrusion flow rate was 1 mL / min.

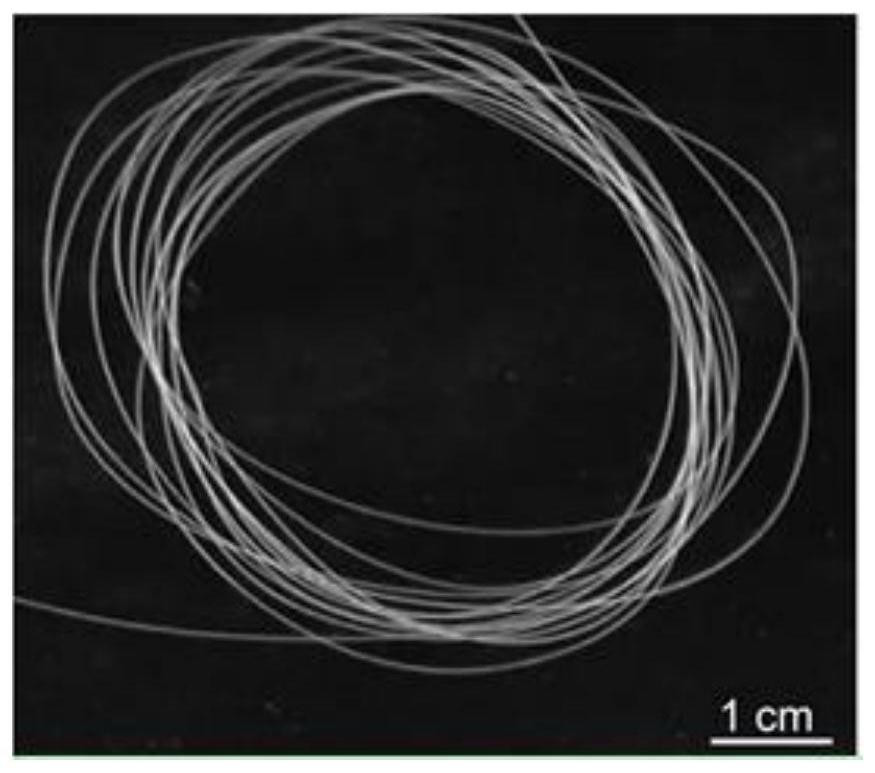

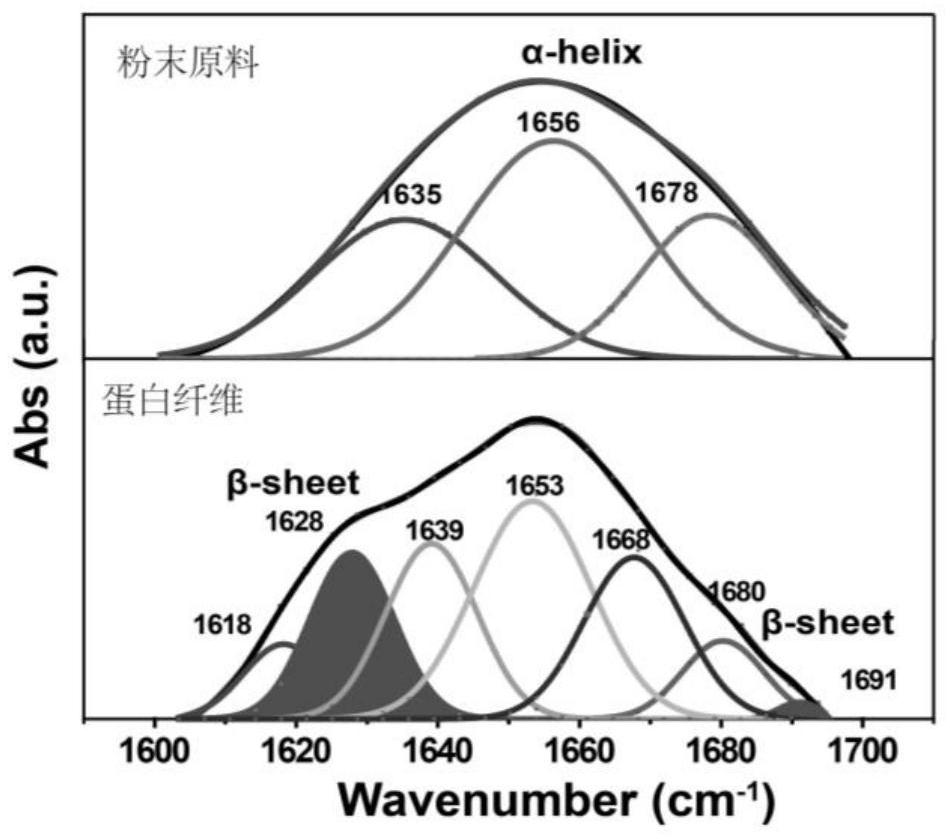

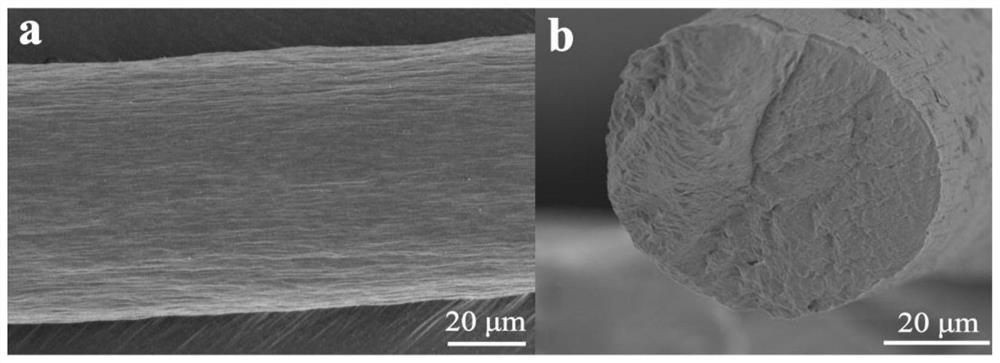

[0040] 3. Get the nascent protein fiber stretching 3 times in step 2, obtain a large amount of slender macroscopic protein fiber (see figure 1 ). from figure 2 According to the infrared spectrum data, the structure of bovine serum albumin powder is dominated by α-helix, and the β-fold in the formed protein fiber structure is significantly increased, which proves that amyloid transformation has occurred du...

Embodiment 2

[0045] 1. After mixing 1.00 g of bovine serum albumin, 2 mL of 500 mmol / L pH=5 tris(2-carboxyethyl) phosphine hydrochloride aqueous solution, and 3 mL of trifluoroethanol, react at 25°C for 30 minutes to generate protein chains Unfolded to obtain a spinning solution.

[0046] 2. Under the driving force of the syringe pump, the spinning solution in step 1 is squeezed into the water from the spinneret to obtain primary protein fibers with an amyloid-like structure on a large scale; the diameter of the spinneret is 0.51mm, and the The extrusion flow rate was 1 mL / min.

[0047] 3. Take the nascent protein fiber in step 2 and stretch it three times, and after drying, a large number of slender macroscopic protein fibers are obtained. After testing, the fracture strength is 142±17MPa, the Young's modulus is 2.9±0.5GPa, and the toughness is 58±12MJ / m 3 .

Embodiment 3

[0049] In step 1 of this example, 1.25 g of bovine serum albumin, 1 mL of 500 mmol / L pH=4 tris(2-carboxyethyl) phosphine hydrochloride aqueous solution, and 4 mL of trifluoroethanol were mixed and reacted at 25°C The protein chains were unfolded for 30 minutes to obtain a spinning solution. Other steps were the same as in Example 2, and a large number of elongated macroscopic protein fibers were obtained. After testing, the fracture strength is 169±18MPa, the Young's modulus is 2.8±0.6GPa, and the toughness is 53±13MJ / m 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com