Hydrogenated isoprene/styrene block coupling polymer optical cable ointment gelling agent, preparation method thereof and application thereof in optical cable ointment

A technology for hydrogenating isoprene and styrene blocks, which is applied in optics, light guides, optical components, etc., can solve the problems of high molecular weight and affecting the dropping point of copolymers, achieve excellent performance, improve dropping point and dynamic viscosity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

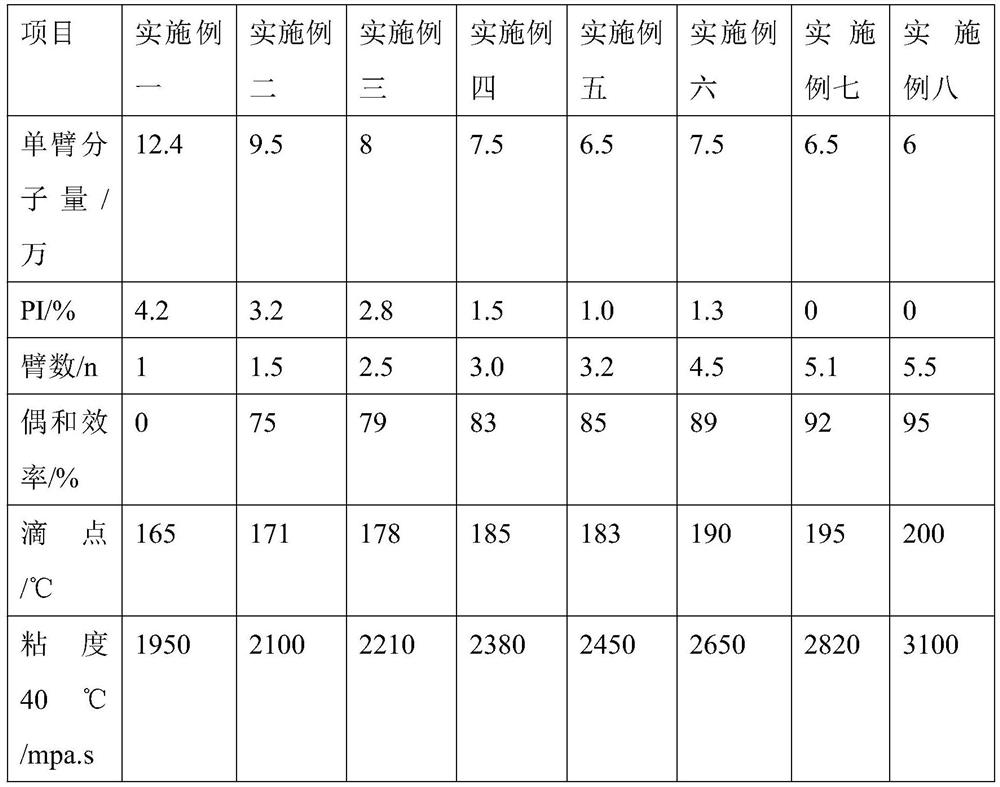

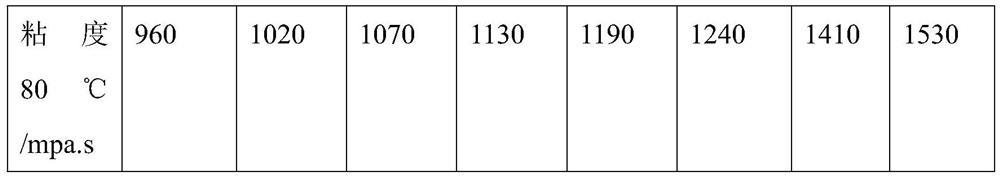

Examples

preparation example Construction

[0059] The preparation method of filling ointment for optical fiber and optical cable: Add 16g of diblock hydrogenated styrene-isoprene and 184g of second base oil into a 500mL beaker, heat and stir in a heating mantle, and control the temperature at 100-120°C until it becomes a uniform viscous ointment.

[0060] The dropping point of optical cable filling ointment shall be measured according to GB 4929-85 standard.

[0061] 300% tensile strength, tensile strength at break, elongation at break, permanent deformation test standard: measured according to GB / T528-92 standard;

[0062] Hardness test standard: measured according to GB / T531-99 standard;

Embodiment 1

[0064] Using the lithium-based initiator anionic polymerization process, add 3000ml cyclohexane to a 5-liter polymerization kettle purified by nitrogen, and add tetrahydrofuran in an amount of 100mg / kg solvent, raise the temperature of the solvent system to 50°C, and add The calculated amount of n-butyllithium is 2.4mmol, and the initiation reaction is carried out by adding 210g pentadiene in one stage, the reaction polymerization temperature is controlled at 50-110°C, and after stirring for 30-60 minutes, styrene will be prepared according to the design (styrene is pentadiene The weight ratio of alkene is 3 / 7) into the active polymer, during which the reaction temperature is controlled at 55-85°C, the reaction is stirred for 30-60min, and about 5ml of ethanol is added to terminate. After the polymerization, the polymer is pressed into 5 liters In the hydrogenation kettle, control the temperature at 50-100°C, add 68mmg methyl benzoate to the hydrogenation kettle, stir for 5-20m...

Embodiment 2

[0071] Adopt lithium series initiator anionic polymerization process, compare with embodiment 1, according to design molecular weight, n-butyllithium add-on is 3.3mmol. The difference is that after the second-stage polymerization reaction is completed, the copolymer is coupled with dichlorodimethylsilane, the addition amount is 1.9mmol, and the coupling temperature is controlled between 50-75°C. The coupling reaction time is about 15-30min. After complete, then add 5ml ethanol to terminate, then according to the hydrogenation process control of embodiment 1, polymer glue liquid is carried out hydrogenation reaction, obtain hydrogenated copolymer, add the antioxidant based on the weight of polymer 0.6% in reaction mixture , and stir for 5 minutes. Finally the product is added to a mixture of steam and water, the solvent is evaporated and the polymer is isolated as a solid suspended in water. The solid is separated, squeezed with a squeeze dehydrator, and devolatilized in a dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com