Radiation refrigeration composite fabric, preparation method and device

A composite fabric and refrigeration technology, applied in lamination devices, chemical instruments and methods, textiles and papermaking, etc., can solve problems such as poor air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042]Another aspect of the present invention also provides a method of producing a radiation cooled coincid fabric, the preparation method comprising:

[0043]Tethasic acid tetraeth ester solution and alkaline solutions are disposed; and

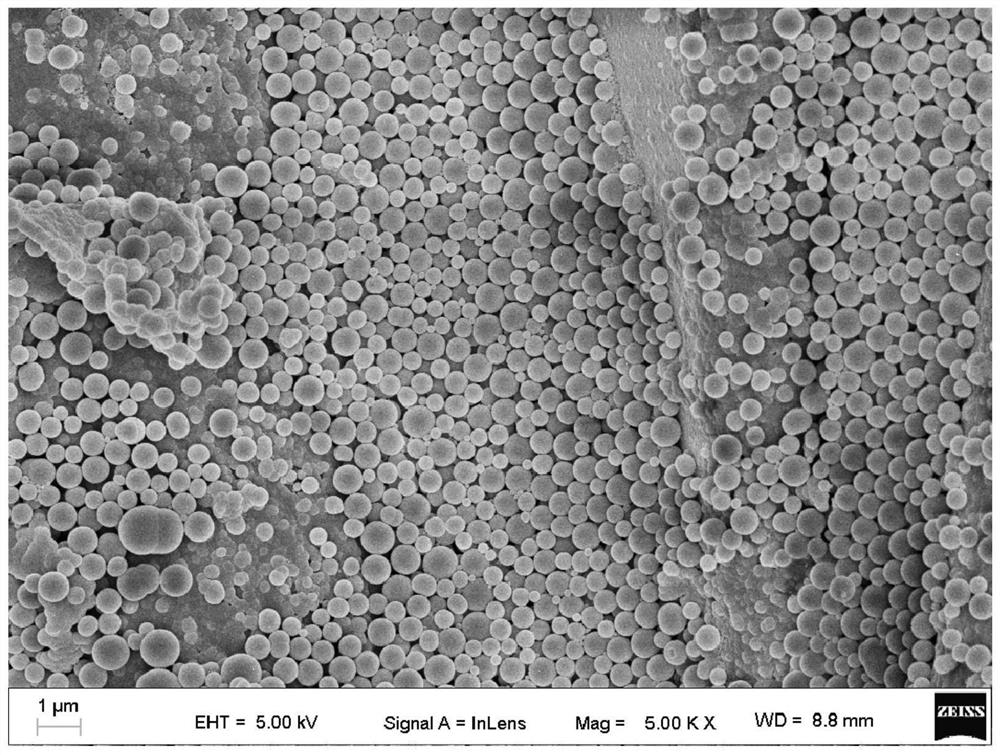

[0044]The silicate solution and the alkaline solution were attached to the surface of the silicate in situ hydrolysis reaction by impregnating or spraying, and the reaction time was 1-10 min, and the in situ hydrolyzed reaction product is a silica microsphere. The excess moisture and solvent drying, that is, the surface is uniformly covered with a silica microspheres such as silica microspheres.

[0045]In the present embodiment, by weighing a certain mass of silicate is dissolved in a certain mass-absorbent ethanol, a concentration of tetraeth ethanol solution is disposed, placed in a pressure spray gun; A certain volume of concentrated ammonia water (25% mass fraction) is added to a certain amount of pure water dilution, configured to be a concentration...

Embodiment 1

[0050]Example 1: 30 g of ethyl silicate and 120 g of anhydrous ethanol were weighted with a beaker, and the tetraethyl silicate was mixed in anhydrous ethanol, and the tetraethyl ethanol solution of 150 g of a concentration of 20% was configured. The 30 g of the 30g mass fraction was 12% concentrated water was weighed with a beaker, and 120 g of a mixture was mixed, and a 150 g of a concentration of 5% ammonia solution was configured. A nylon cloth that is 40 g from 1m × 1m is removed, that is, the amount of silicate solution and the spray amount of the ammonia solution of silicate is 150 g / m.2, The four ethyl silicate solution and the ammonia solution are disposed in the air pressure spray, respectively, and evenly sprayed on the nylon cloth. After 1min hydrolysis, drying under 60 ° C, resulting radiation cooled composite fabric . The silica microspheres are observed by microscopy and measured their size. According to national standard GB-T 5453-1997, "Determination of textile fa...

Embodiment 2

[0052]Example 2: The concentration of tetraeth ester solution in this embodiment was 50%, and the remaining conditions were the same as those in Example 1.

[0053]The average size of the silica microspheres prepared in this example is 2000 nm, and the gas permeability of the composite fabric is 146ml / (cm2· MIN), the infrared light emission rate of 8-13 μm in wavelength is 87%, the radiation power is 91w / m2The temperature drop is 8 ° C. As compared with the Example 1, it can be found that increase the concentration of the tetraeth ester solution of the silicate solution, the obtained silica microsphere size is increased, and the gas permeability of the composite fabric, the infrared light emission rate and the radiation power are lowered, and the cooling effect is deteriorated. At the same time, the flexibility of the composite fabric is deteriorated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com