Environmental-friendly copper surface roughening solution and preparation method thereof

A technology of copper surface and roughening liquid, applied in the field of roughening liquid, can solve the problems of increasing costs, destroying the ecological balance and loss of water environment and biological communities, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

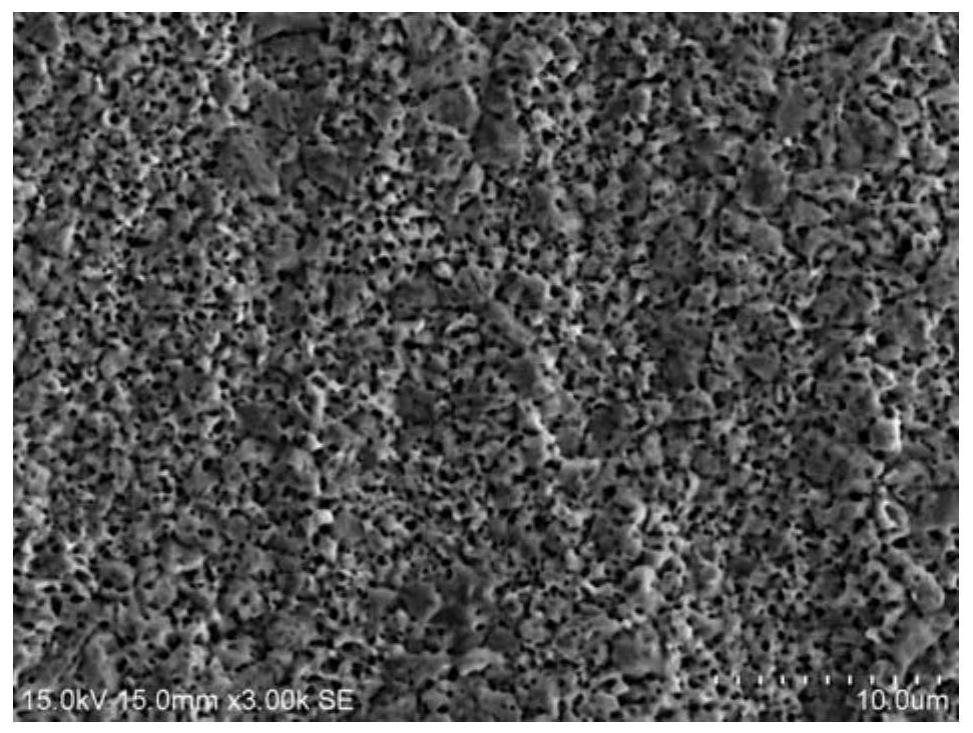

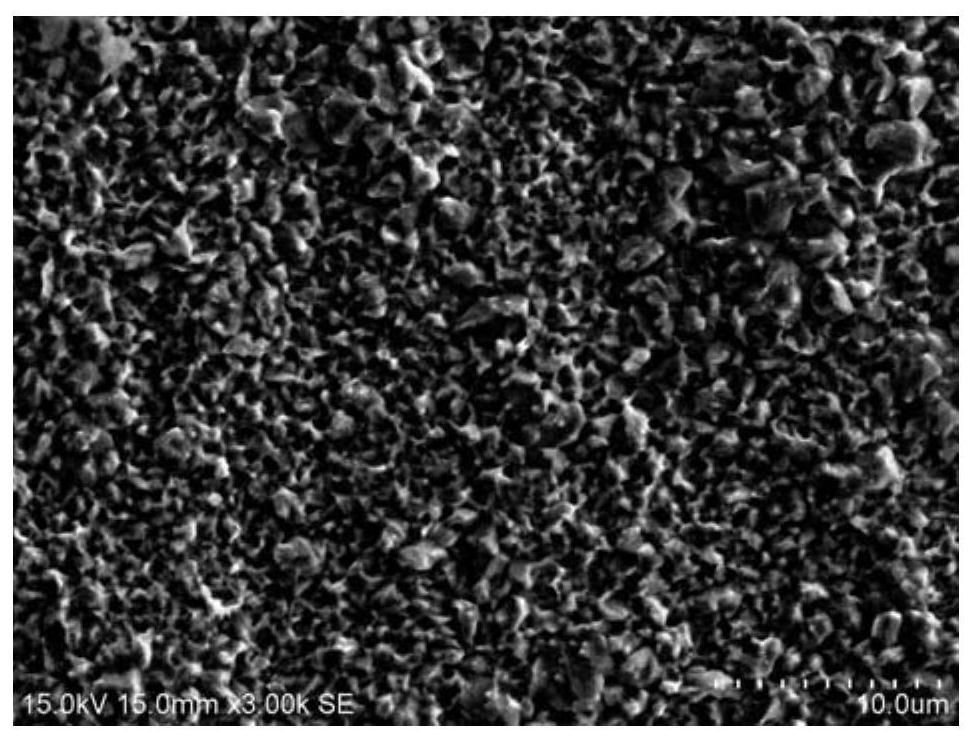

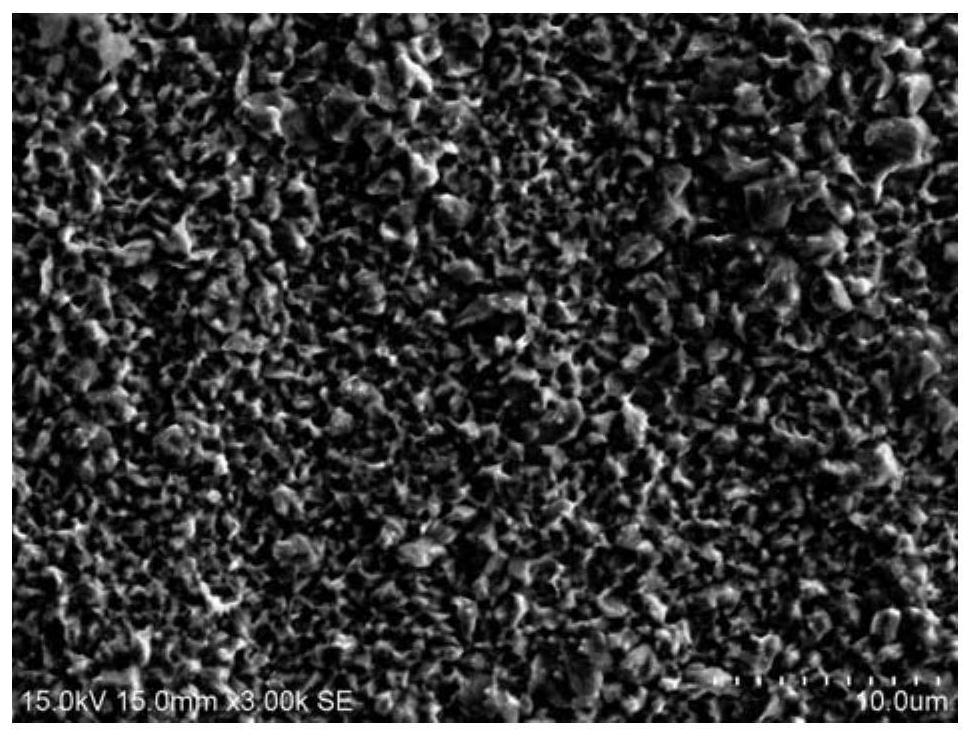

Image

Examples

preparation example Construction

[0042] A preparation method of environment-friendly copper surface roughening liquid, the steps are as follows:

[0043]Step 1: Weigh the source of divalent copper ions and the source of chloride ions in the formula, add them to deionized water and stir to dissolve;

[0044] Step 2: Weighing the amount of inorganic acid, fatty amine and pyridine derivatives into the solution prepared in Step 1, and stirring evenly;

[0045] Step 3: Dilute the solution obtained in Step 2 to the required volume with deionized water, and stir evenly to obtain the roughened solution.

[0046] One, embodiment and its preparation

Embodiment 1

[0048] 1) Including the following components and their mass concentrations:

[0049] Divalent copper ion 5g / L, derived from copper oxide;

[0050] Chloride ion 5g / L, derived from sodium chloride;

[0051] Inorganic acid 20g / L, derived from sulfuric acid;

[0052] Monoethanolamine 0.001g / L;

[0053] 3-picoline 0.001g / L;

[0054] The balance is deionized water;

[0055] 2) Preparation method:

[0056] Step 1: Weigh the source of divalent copper ions and the source of chloride ions in the formula, add them to deionized water and stir to dissolve;

[0057] Step 2: Weigh the inorganic acid, aliphatic amine and pyridine derivative in the formula amount in the solution prepared in step 1, and stir evenly;

[0058] Step 3: Use deionized water to dilute the solution obtained in Step 2 to the required volume, and stir evenly to obtain the coarsening solution;

Embodiment 2

[0060] 1) Including the following components and their mass concentrations:

[0061] Divalent copper ion 10g / L, derived from copper chloride;

[0062] Chloride ion 35g / L, derived from copper chloride and sodium chloride;

[0063] Inorganic acid 30g / L, derived from sulfuric acid;

[0064] Monoethanolamine 0.5g / L;

[0065] 3-picoline 0.1g / L;

[0066] The balance is deionized water;

[0067] 2) The preparation method is the same as in Example 1;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com