Pomelo seed polysaccharide extraction process

A polysaccharide extraction and process technology, applied in the field of grapefruit seed polysaccharide extraction process, achieves the effects of high extraction rate, optimized process conditions and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Example 1 Shatian pomelo seed polysaccharide extraction process

[0059] Include the following steps:

[0060] 1. Sample preparation: Shatian pomelo seeds were screened to remove impurities, dried at 50°C to constant weight, and then crushed through a 20-mesh sieve to obtain Shatian pomelo seed powder. Store at -20°C for later use.

[0061] 2. Degreasing treatment: Take a filter paper tube (weighed) with a specification of 33mm×80m, add 10.00g of Shatian pomelo seed powder into the above filter paper tube, install the metal filter tube connector on the filter paper tube, and remove the filter paper after installation. Buckle the barrel on the magnet ring of the sample rod; measure 100mL of n-hexane into the aluminum extraction cup, place the extraction cup on the cup holder, and move the extraction cup into 2055 Sostec-Avanti extraction In the device, leaching at a constant temperature of 160°C for 22 minutes, n-hexane was condensed and rinsed for 41.66 minutes, and t...

Embodiment 2

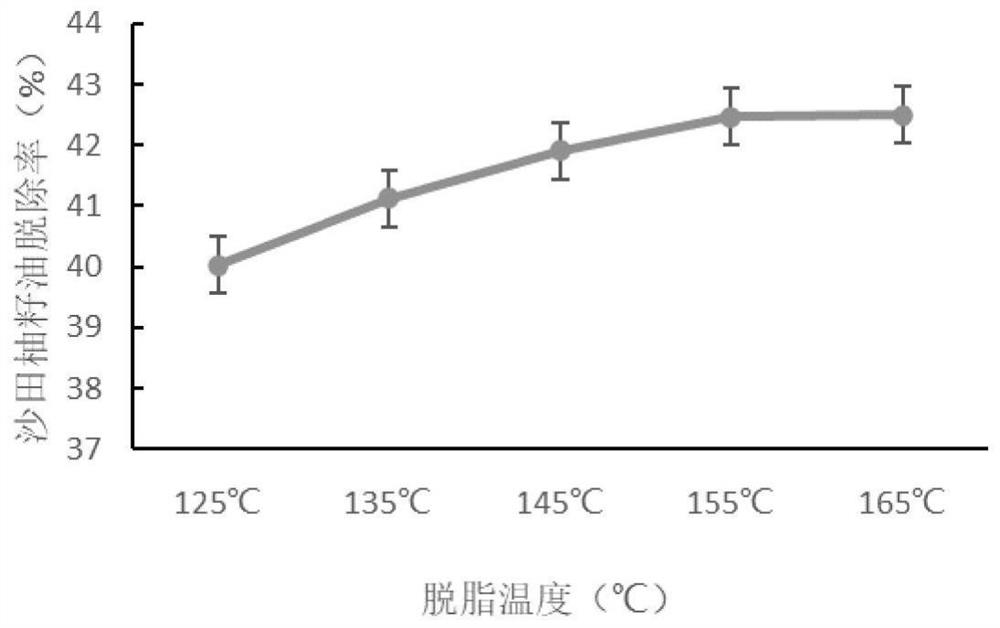

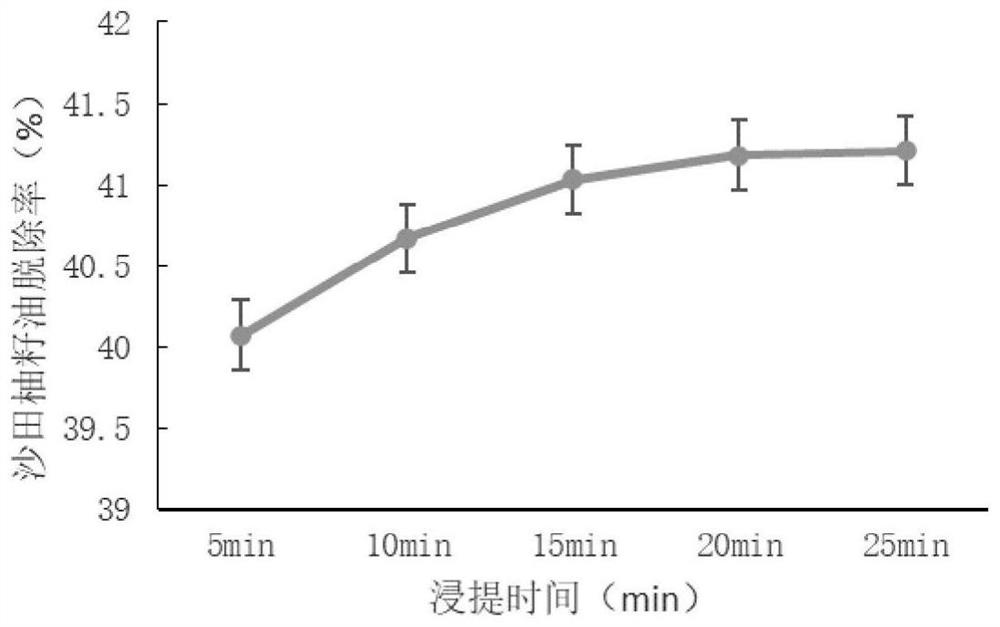

[0069] Example 2 Optimization of Shatian pomelo seed degreasing process

[0070] 1. Determination of oil removal rate of pomelo seed in Shatian

[0071] Weigh the weight of a 33mm×80m filter paper cylinder as m 1 , add the pretreated Shatian pomelo seed powder into the weighed filter paper cylinder, and record the weight as m 2 , Install the metal filter cartridge joint on the filter paper cartridge, and buckle the filter paper cartridge on the magnet ring of the sample rod after installation. Use a measuring cylinder to take 100mL of organic solvent into the aluminum extraction cup, place the extraction cup on the cup holder, move the extraction cup into the 2055 Sostec-Avanti extraction device, set the extraction temperature to 135 At a constant temperature of ℃, set the extraction time to 15 minutes, the rinsing time to 30 minutes, and the solvent recovery time to 10 minutes. After the extraction, place the solid residue and the filter paper tube in a hot air drying oven ...

Embodiment 3

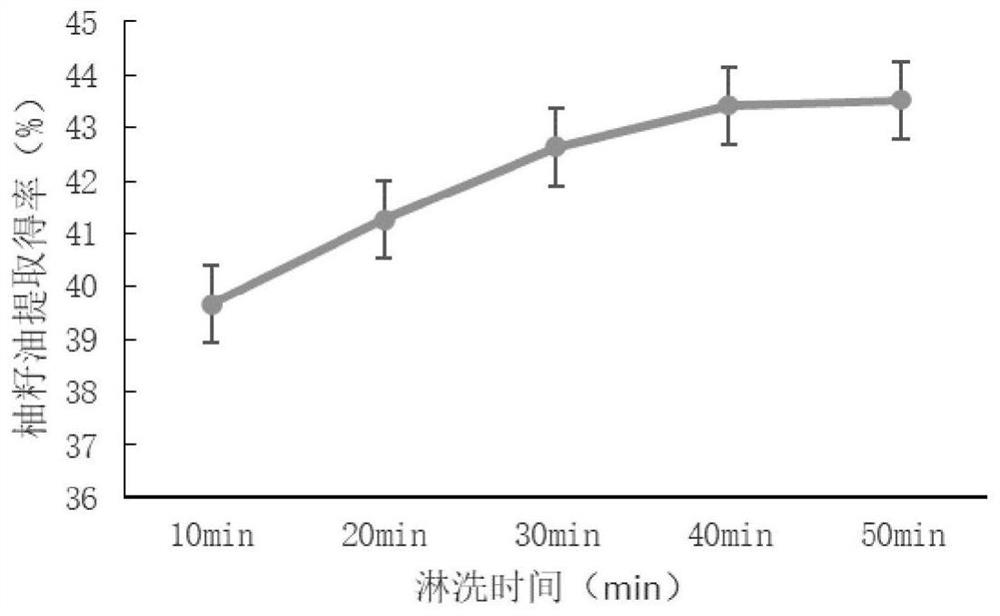

[0120]R1=44.64+1.41A+1.65B+1.82C+0.65AB+0.8AC+0.53BC-2.51A2-2.11B2-2.38C2Example 3 Optimization of Shatian pomelo seed polysaccharide extraction process

[0121] 1.1 Standard curve drawing

[0122] Accurately weigh 10 mg of glucose dried at 120°C to a constant weight, put it in a 100 ml volumetric flask, dissolve it in distilled water and constant volume to obtain a glucose standard solution with a concentration of 0.1 mg / ml. Accurately measure 0.0, 0.2, 0.4, 0.6, 0.8, 1.0, 1.2, 1.4, 1.6ml of each standard solution and put them in a 10ml volumetric flask, add distilled water to make up to 2ml, then add 1.0ml of phenol with a volume fraction of 5% solution and 7ml of concentrated sulfuric acid solution, shake well, heat in a water bath at 25°C, cool to room temperature, measure the absorbance value at 490nm, take the absorbance value as the ordinate, and the glucose concentration (mg / ml) as the abscissa, and draw a standard curve.

[0123] 1.2 Extraction of polysaccharides

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com