Monatomic Ag-loaded nitrogen-doped TiO2 catalyst as well as preparation and application thereof

A nitrogen doping and catalyst technology, which is applied in the fields of catalytic materials and environmental protection, achieves the effects of simple and easy preparation method, no attenuation in the ability of catalytically degrading formaldehyde, and increased absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

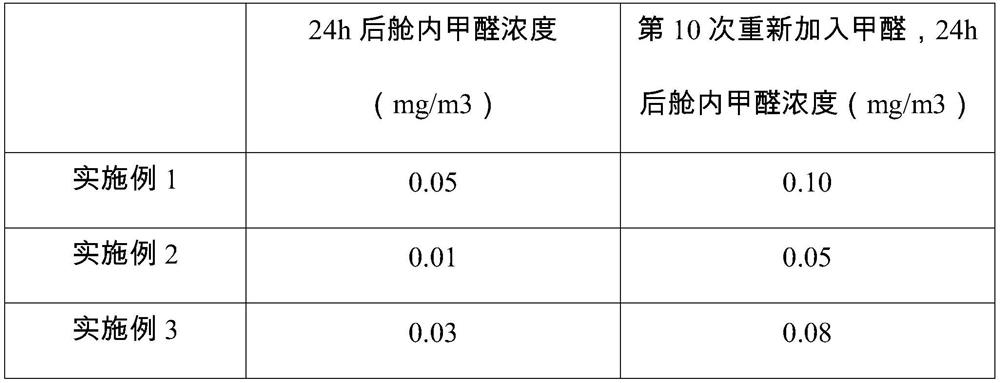

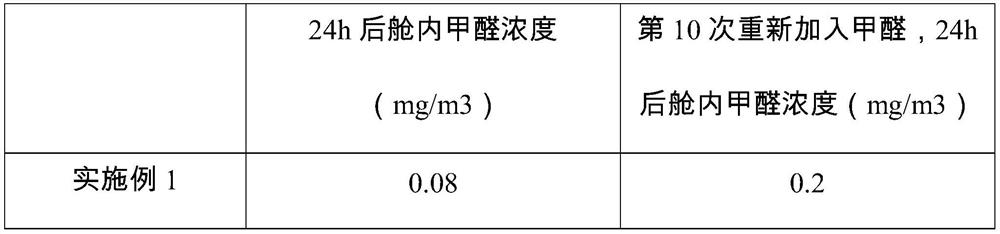

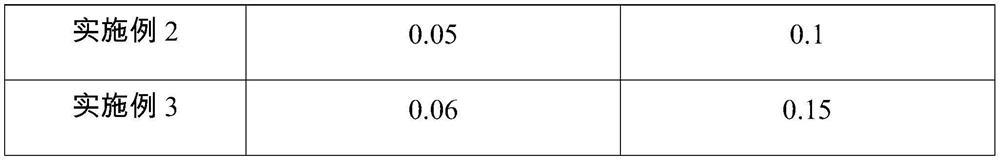

Examples

preparation example Construction

[0030] Single-atom Ag-loaded nitrogen-doped TiO of the present invention 2 The preparation method of catalyst is characterized in that, comprises the steps:

[0031] (1) dissolving the titanium source in an organic solvent to obtain solution A;

[0032] (2) dissolving silver source and nitrogen source in a mixed solvent of water, acid and organic solvent to obtain solution B;

[0033] (3) Add solution B dropwise to solution A under the action of an ultrasonic instrument, after complete dropwise addition, continue ultrasonication for 1-5 hours to form a stable gel;

[0034] (4) Dry the gel in step (4) in a constant temperature drying oven to obtain dry gel, grind it into powder, and place it in a hydrogen atmosphere furnace for high-temperature roasting to obtain single-atom Ag-loaded nitrogen-doped nano-TiO 2 catalyst.

[0035] Preferably, the ratio of the titanium source to the organic solvent in step (1) is (0.01-1):1.

[0036] Preferably, the material ratio of water, ac...

Embodiment 1

[0050](1) 0.1mol of titanium tetrachloride is added dropwise to 0.1mol of ethanol under the action of a magnetic stirrer, fully stirred, and mixed uniformly to obtain solution A;

[0051] (2) Get the ethylene glycol of 1mol water, 0.1mol hydrochloric acid and 0.1mol and mix under the effect of magnetic stirrer to obtain mixed solvent; Under the effect of magnetic stirrer, add 0.001mol silver nitrate and 0.01mol ammonium acetate, fully stir, Mix evenly to obtain solution B;

[0052] (3) Add solution B dropwise to solution A at a rate of 1mL / min under the action of an ultrasonic instrument (temperature 0°C, frequency 50HZ), and after complete dropwise addition, continue ultrasonication for 1 hour to form a stable gel;

[0053] (4) Dry the gel in step (4) in a constant temperature drying oven at 50°C for 24 hours to obtain dry gel, grind it into powder, and place it in a hydrogen atmosphere furnace for 300°C for 6 hours to obtain a monoatomic Ag-loaded nitrogen-doped gel. Doped ...

Embodiment 2

[0055] (1) 0.1 mol of tetraisopropyl titanate was added dropwise to 10 mol of methanol under the action of a magnetic stirrer, fully stirred, and mixed uniformly to obtain solution A;

[0056] (2) Take 1mol of water, 1mol of nitric acid and 10mol of methanol and mix them uniformly under the action of a magnetic stirrer to obtain a mixed solvent; under the action of a magnetic stirrer, add 0.1mol of silver acetate and 1mol of ammonium carbonate, fully stir, and mix evenly to obtain solution B ;

[0057] (3) Add solution B dropwise to solution A at a rate of 10mL / min under the action of an ultrasonic instrument (temperature is 25°C, frequency is 100HZ). After the drop is complete, continue ultrasonication for 5 hours to form a stable gel;

[0058] (4) Dry the gel in step (4) in a constant temperature drying oven at 100°C for 6h to obtain dry gel, grind it into powder, and place it in a hydrogen atmosphere furnace at 500°C for 0.5h to obtain monoatomic Ag-loaded nitrogen doped T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com