Raw fluorosilicone rubber with high vinyl activity and preparation method thereof

A fluorosilicone rubber and high vinyl technology, which is applied in the field of high vinyl active fluorosilicone rubber and its preparation, can solve the problems of processing performance, mechanical properties, insufficient vinyl activity and utilization rate, and inability to achieve good cross-linking effect and other problems, to achieve the effect of simple and effective preparation method, avoiding low utilization rate and reducing shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

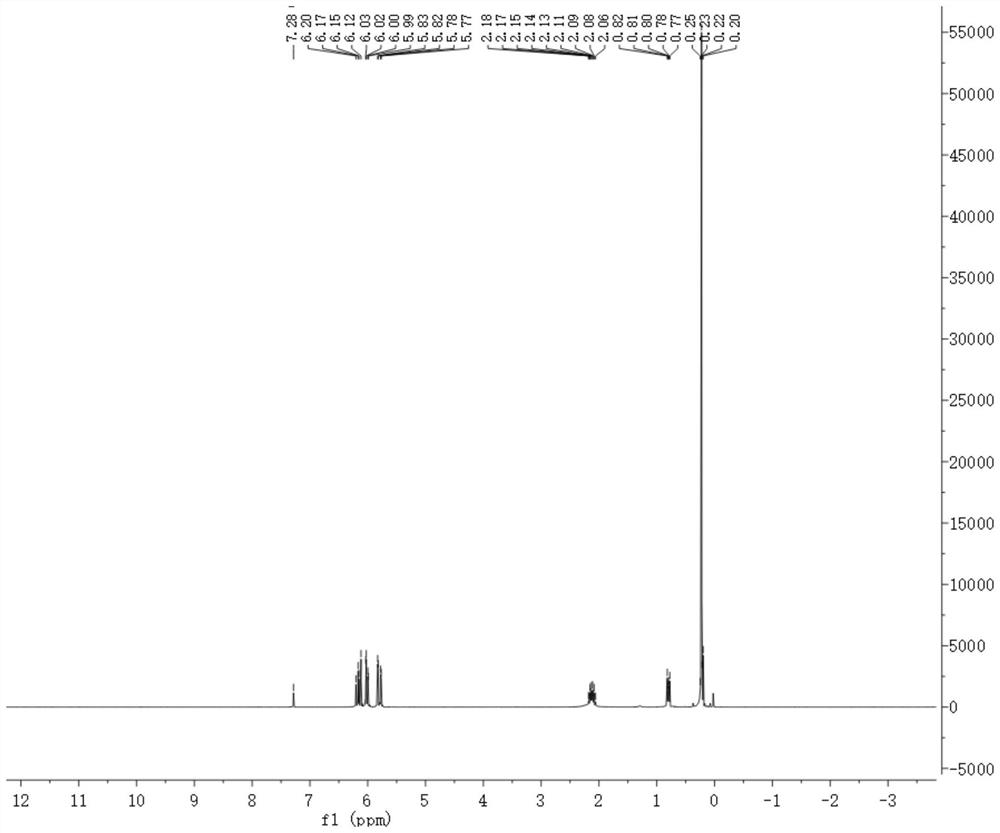

[0065] The preparation of vinyl fluorine silicon monomer comprises steps as follows:

[0066] (1) Under nitrogen protection, add 926g trifluoropropyl trichlorosilane and 1389g ethyl acetate to the reactor equipped with mechanical stirring, thermometer, condenser, constant pressure dropping funnel, start stirring and mix the materials evenly, Use an ice-water bath to lower the temperature of the kettle to 0-10°C, then dropwise add a mixture of 470g of vinyldimethylsilanol (purity 95.6%) and 445g of triethylamine to the kettle for dechlorination reaction, the reaction is exothermic, dropwise During this period, keep the temperature of the kettle at 0-10°C, continue stirring for 1h-2h after the dropwise addition is completed, then return the system to room temperature, remove triethylamine hydrochloride by filtration, wash the filter cake with 200g of ethyl acetate, collect the filtrate, and obtain 1-ethylene Base-3-trifluoropropyl-1,1-dimethyl-3,3-dichlorodisiloxane solution;

...

Embodiment 2

[0070] The preparation of vinyl fluorine silicon monomer comprises steps as follows:

[0071] (1) Under the protection of nitrogen, add 833g trifluoropropyltrichlorosilane and 1200g ethyl acetate to the reaction kettle equipped with mechanical stirring, thermometer, condenser, constant pressure dropping funnel, start stirring and mix the materials evenly, Use an ice-water bath to lower the temperature of the kettle to 0-10°C, then dropwise add a mixture of 423g vinyldimethylsilanol (95.6% purity) and 400g triethylamine to the kettle for dechlorination reaction, the reaction exothermic, dropwise During this period, keep the temperature of the kettle at 0-10°C, continue stirring for 1h-2h after the dropwise addition is completed, then return the system to room temperature, remove triethylamine hydrochloride by filtration, wash the filter cake with 200g of ethyl acetate, collect the filtrate, and obtain 1-ethylene Base-3-trifluoropropyl-1,1-dimethyl-3,3-dichlorodisiloxane solutio...

Embodiment 3

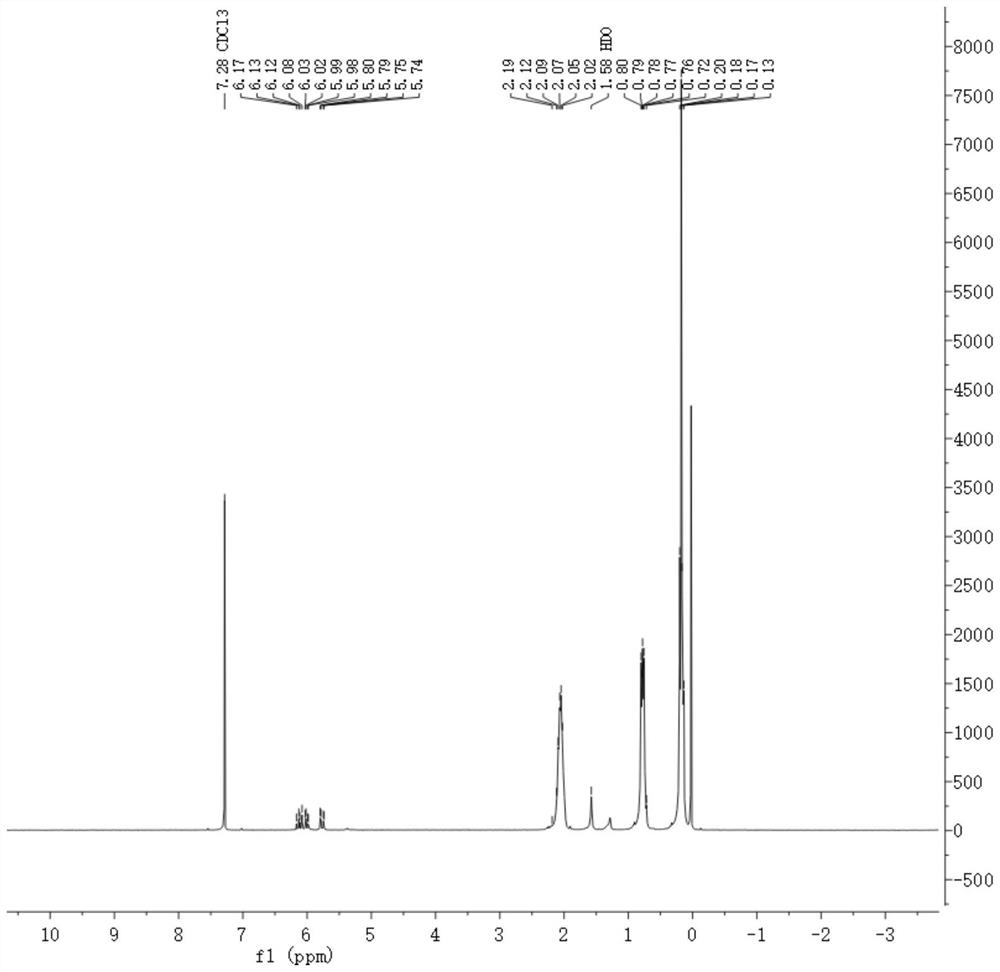

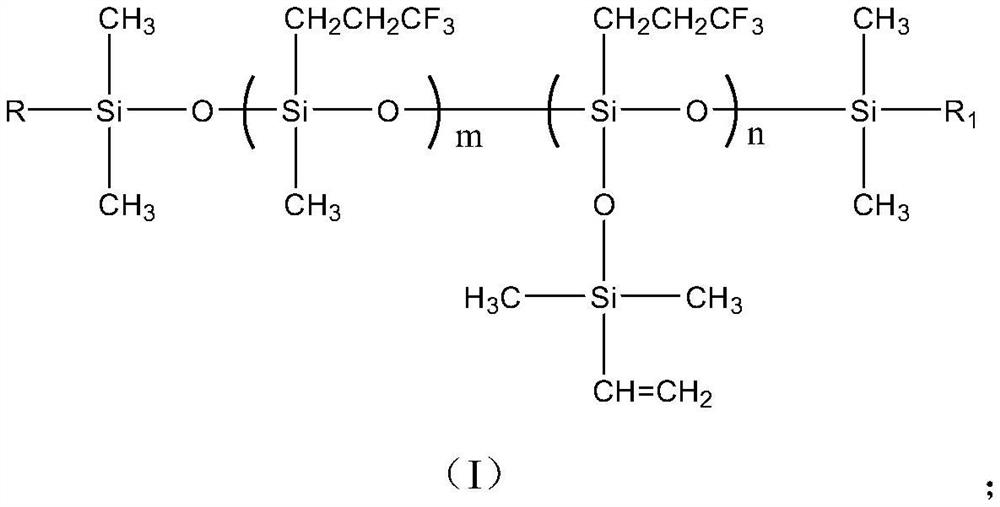

[0074] A high vinyl active fluorosilicone rubber raw rubber with the following structure:

[0075]

[0076] The preparation steps are as follows:

[0077] (1) Add 5200g trimethyltri(3,3,3-trifluoropropyl)cyclotrisiloxane (D 3 F) and 56g of vinyl fluorosilicon monomer of formula (II), start stirring, and dehydrate under the conditions of 40°C to 50°C and -0.099MPa to -0.1MPa for 2h;

[0078] (2) Use high-purity nitrogen to restore the pressure, then add 30g vinyl dimethyl silanol (purity 95.6%) and 4.3g sodium hydroxide alkali gel (NaOH content 4.02%) to the kettle and slowly heat up to 120°C for copolymerization Reaction, after the reaction starts, keep stirring at 120°C to 130°C for 3h;

[0079] (3) After the reaction is complete, add 90g of vinyldimethylacetoxysilane into the kettle, keep stirring at 100°C to 120°C for 12h for neutralization and capping;

[0080] (4) Under the pressure of -0.099MPa to -0.1MPa, raise the temperature to 200-220°C, remove small molecules ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com