Preparation method of functional glycosyl ionic liquid

A technology of functional sugars and ionic liquids, applied in the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve the problems of easy pollution of the environment and poor performance of ionic liquids, and achieve high sustainability and thermal stability sex-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

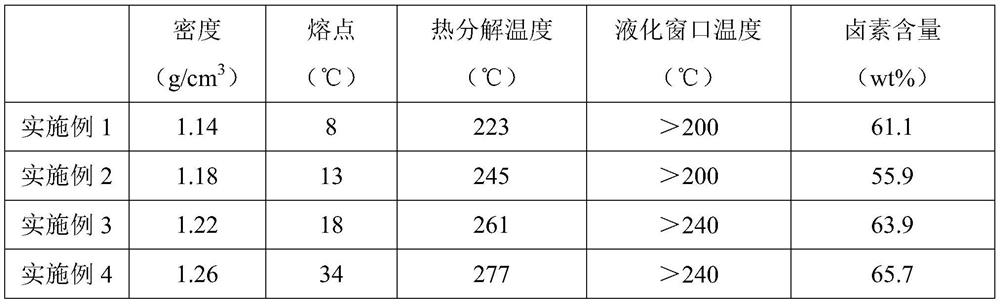

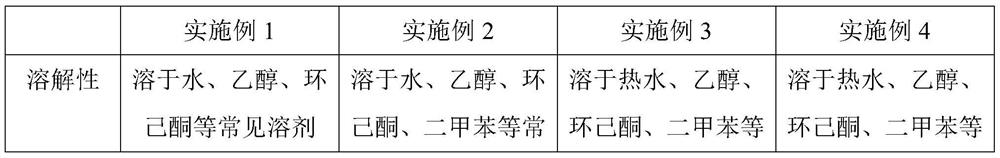

Examples

Embodiment 1

[0029] A method for preparing a functional glycosyl ionic liquid provided in this embodiment is characterized in that it comprises the following steps:

[0030] Step 1: Put glucose and N,N-dimethylacetamide after dehydration into the reactor, the amount of glucose added is 0.1mol, the amount of N,N-dimethylacetamide added is 200ml, in 0 Stir under the condition of ℃, after the glucose dissolves to form a homogeneous solution, add zinc acetate catalyst, the mass of the added zinc acetate catalyst is 0.19g, and then use the dropping funnel to evenly drop 0.1mol of thionyl chloride to the reaction within 2h In the kettle, stir and keep warm at 0°C for 3h, then raise the temperature to 80°C, continue to keep warm for 8h, then cool to normal temperature to obtain a monochloroglucose solution, namely solution A

[0031]Step 2: Add the imidazole powder to the monochloride-substituted glucose solution in step 1, i.e. solution A, the amount of imidazole powder added is 0.04 mol, stir a...

Embodiment 2

[0034] A method for preparing a functional glycosyl ionic liquid provided in this embodiment is characterized in that it comprises the following steps:

[0035] Step 1: Put sucrose and dehydrated N-methylpyrrolidone into the reaction kettle, the amount of sucrose added is 0.1mol, the amount of N,N-dimethylacetamide added is 400ml, and stirred at 5°C , after the sucrose is dissolved to form a homogeneous solution, add N,N-dimethylformamide catalyst, the quality of the added N,N-dimethylformamide catalyst is 6.84g, then use the dropping funnel to distill 0.15mol of dibromo Add sulfoxide evenly into the reaction kettle dropwise within 4 hours, stir and keep warm at 5°C for 3 hours, then raise the temperature to 100°C, continue to keep warm for 12 hours, and cool to room temperature to obtain a monobromine-substituted sucrose solution, namely solution A

[0036] Step 2: Add 4,5-dimethylol-2-phenylimidazole powder to the monobrominated sucrose solution in step 1, solution A, the am...

Embodiment 3

[0039] A method for preparing a functional glycosyl ionic liquid provided in this embodiment is characterized in that it comprises the following steps:

[0040] Step 1: put raffinose and dehydrated N,N-dimethylformamide into the reactor, the amount of raffinose added is 0.1mol, and the amount of N,N-dimethylformamide added is 300ml, stir at 2°C, after the raffinose dissolves to form a homogeneous solution, add a zinc oxide catalyst, the quality of the added zinc oxide catalyst is 7.5g, and then use a dropping funnel to dissolve 0.12mol of phosphorus tribromide in 3h Add it dropwise evenly into the reaction kettle, stir and keep warm at 2°C for 3 hours, then raise the temperature to 90°C, continue to keep warm for 10 hours, and cool to room temperature to obtain a monobrominated raffinose solution, namely solution A

[0041] Step 2: Add 4,5-dicarboxyimidazole powder to the monobromo-substituted raffinose solution in step 1, i.e. solution A, the amount of 4,5-dicarboxyimidazole ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap