Lead sulfide quantum dot solar cell and preparation method thereof

A technology of solar cells and quantum dots, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as cumbersome processes, low ligand exchange efficiency, and material consumption, so as to simplify the operation process, improve ligand exchange efficiency, The effect of reducing the consumption of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

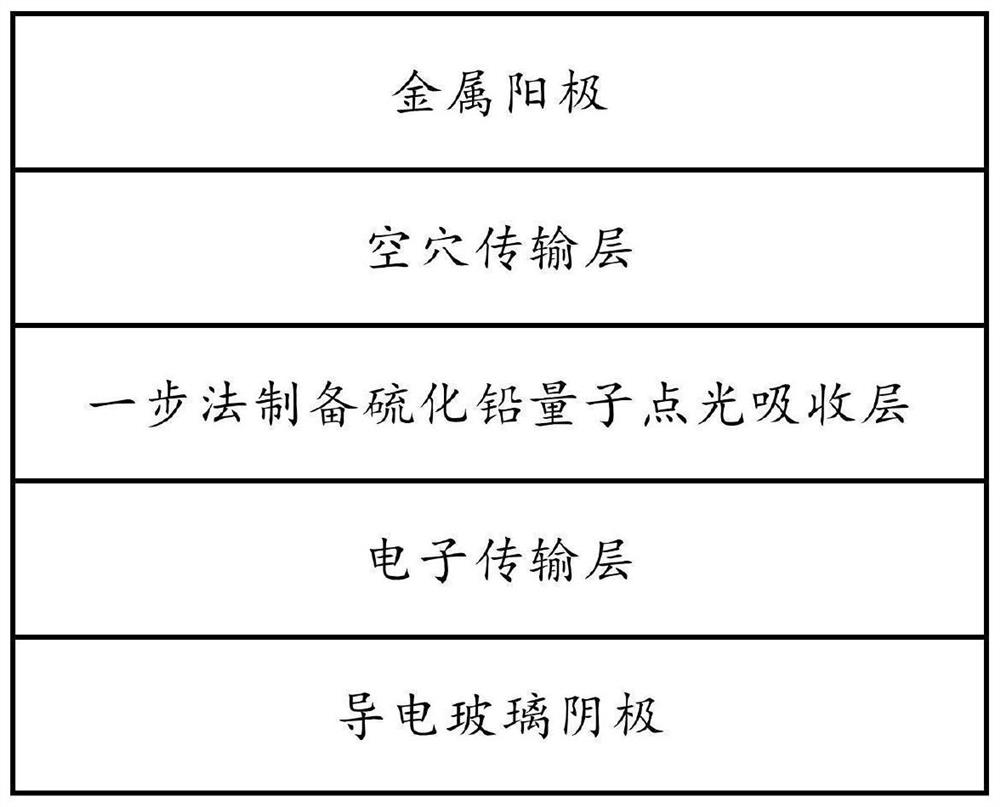

[0034] The invention provides a lead sulfide quantum dot solar cell and a preparation method thereof. A light-absorbing layer of a quantum dot solar cell is prepared by a one-step method to obtain a high-performance lead sulfide quantum dot solar cell. The material PbS of the light-absorbing layer of the lead sulfide quantum dot solar cell provided by the present invention is treated with a solution containing the second ligand in a one-step method to replace the first ligand originally attached to the PbS, effectively removing the long-chain ligand in the light-absorbing layer, The charge transport performance of the light-absorbing layer is increased, and the charge recombination effect of the light-absorbing layer is reduced, thereby improving the photoelectric conversion efficiency of the battery. The lead sulfide quantum dot battery provided by the present invention has the characteristics of excellent efficiency, good stability, and easy preparation, and compared with th...

Embodiment 1

[0044] 1. Preparation of lead sulfide with first ligand: 6 mmol of lead oxide PbO and 15 mmol of oleic acid OA were dissolved in 50 mL of 1-octadecene. The mixed solution was evacuated for 20 minutes, then heated to 100°C and kept for 2 hours, and kept stirring during the process. The lead precursor, lead oleate, was prepared and cooled under nitrogen flow. 630 μl of hexamethyldisilazane TMS was added to 10 mL of 1-octadecene at a temperature of 80° C. to prepare a sulfur precursor, and the temperature of the lead oleate solution dropped to 90° C. at this time. When the temperature of the lead oleate is 85°C, inject the sulfur precursor solution into it quickly, and keep stirring during the process. The preparation of lead sulfide (lead sulfide quantum dot original solution) with long-chain oleic acid ligands was completed.

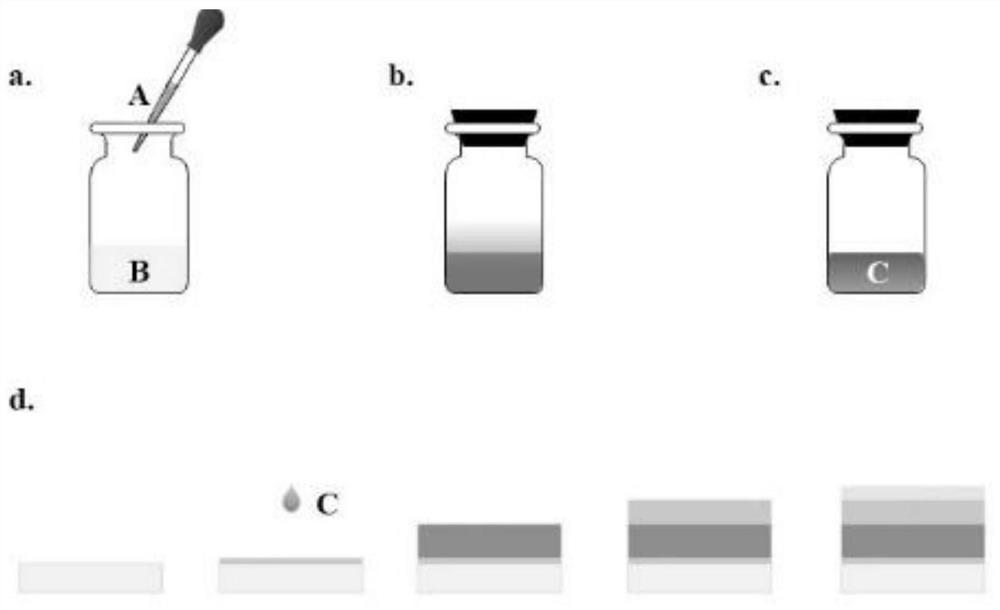

[0045] 2. Ligand exchange to obtain lead sulfide with a second ligand: 20 mL of dimethylformamide DMF, 0.1 mol / L lead iodide PbI 2 , 0.04mol / L lead br...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com