Borosilicate matrix glass material for microchannel plate and preparation method thereof

A micro-channel plate, borosilicate technology, applied in glass manufacturing equipment, manufacturing tools, electron multiplier tubes, etc., can solve the problems of human body and environmental hazards, reduce adsorption residual gas and impurities, and stress is not completely removed, etc. Achieve good corrosion resistance and mechanical properties, solve problems of deformation and breakage, and facilitate widespread application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

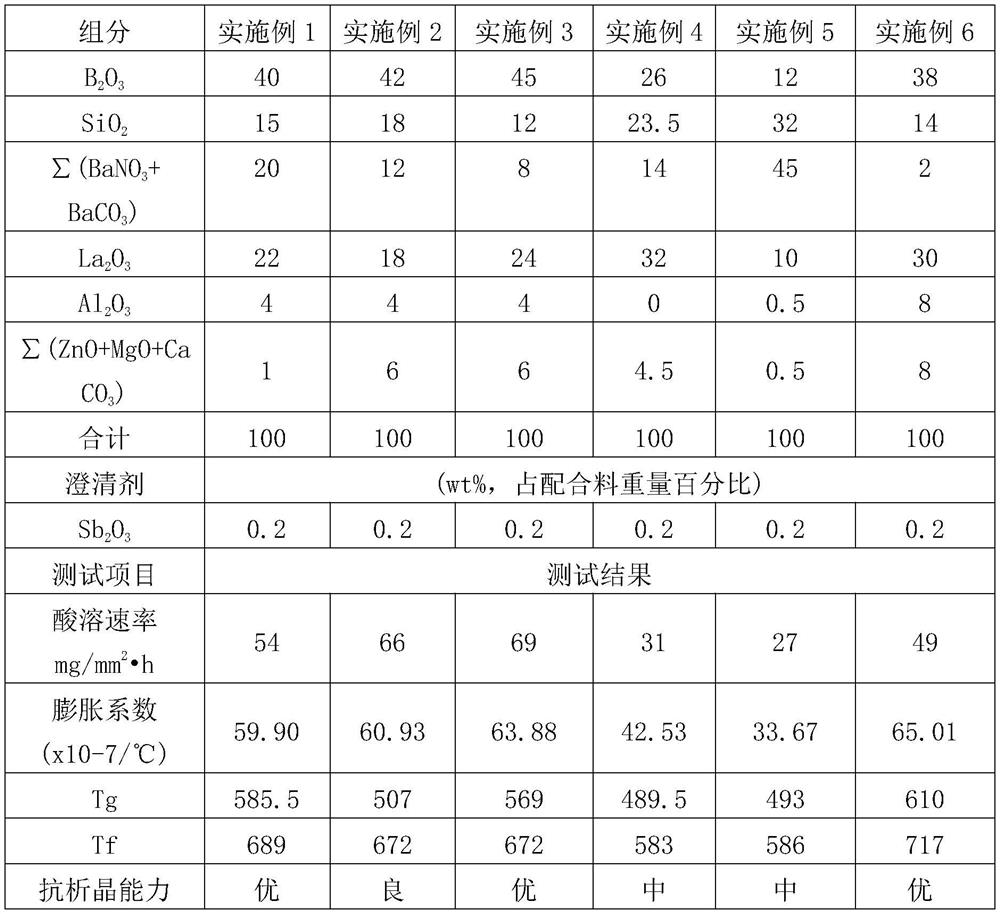

[0036] Embodiment: The preparation core glass rod technology of the present invention is to be raw material mixing with boric acid, silicon dioxide, nitric acid dam or carbonate dam, lanthanum oxide, aluminum oxide, zinc oxide, magnesium oxide, calcium carbonate, add and account for the weight of batch 0.2 % clarifier Sb 2 o 3 , the batch materials were clarified by high temperature melting at 1450°C, and the core glass rod was cast at 1380°C; the specific components and test results of the core glass rod are shown in Table 1.

[0037] Table 1:

[0038]

[0039] Σ( ) in Table 1 represents the total content of each compound represented by the chemical formula in parentheses, and not all of the compounds are required.

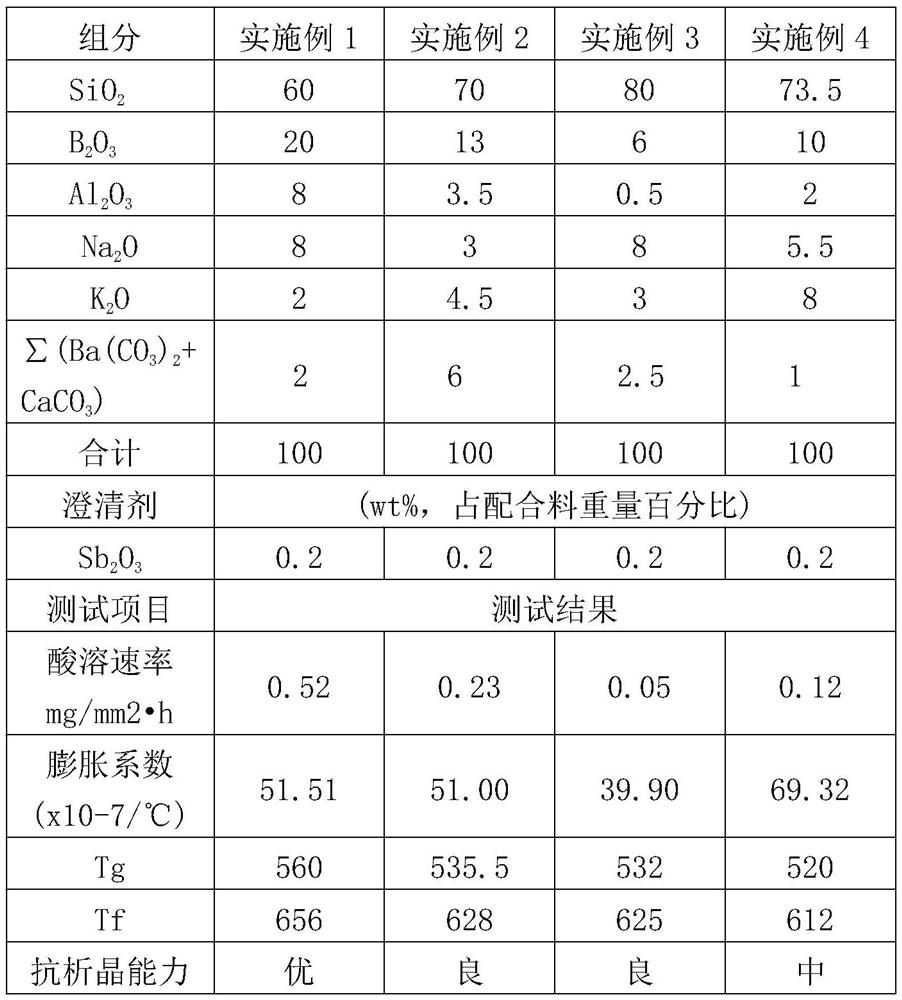

[0040] The process of preparing the leather glass rod of the present invention is to mix silicon dioxide, boric acid, aluminum oxide, potassium oxide, sodium oxide, carbonate dam, and calcium carbonate as raw materials, and add clarifier Sb accounting for 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com