Method for producing D-1, 2, 4-butantriol by simultaneous saccharification and fermentation of corncobs

A simultaneous saccharification and fermentation and corn cob technology, applied in the biological field, can solve the problems of many steps and unfavorable for large-scale fermentation, and achieve the effects of simple operation, large commercial production space, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1 Containing the construction of YjhG gene strain

[0032] (1) Use primers at the 5' end and 3' end of the YjhG gene to introduce restriction sites (NcoI and HindIII), perform double restriction digestion on the YjhG gene and the pCWJ plasmid, and then connect the YjhG gene to the pCWJ vector;

[0033] (2) Transfer the above recombinant vector into the competent cells of Escherichia coli Trans 1T1 (Quanshijin Biotechnology Co., Ltd.), spread on LB plates with 50mg / L chloramphenicol resistance, and culture overnight at 37°C;

[0034] (3) Pick a single colony grown on the plate, transfer it to LB medium containing 50mg / L chloramphenicol resistance, then extract the plasmid, and then perform digestion verification with restriction enzymes Spe I and Kpn I , finally obtained the recombinant plasmid pCWJ-YjhG.

[0035] Referring to the above method, proceed to prepare the recombinant plasmids pTRC99a-xylB-mdlC and pTRC99a-yjhG-adhP.

Embodiment 2

[0036] Example 2 Recombinant Escherichia coli uses xylose as a substrate to ferment and produce 1,2,4-butanetriol

[0037] Streak and activate the genetically engineered bacteria containing the recombinant plasmid pTRC99a-xylB-mdlC and the recombinant plasmid PCWJ-yjhG-adhP on the LB plate (streptavidin resistance and ampicillin resistance), pick a single colony, insert 5 mL LB culture culture medium at 37°C, 200 rpm for 7-10 h.

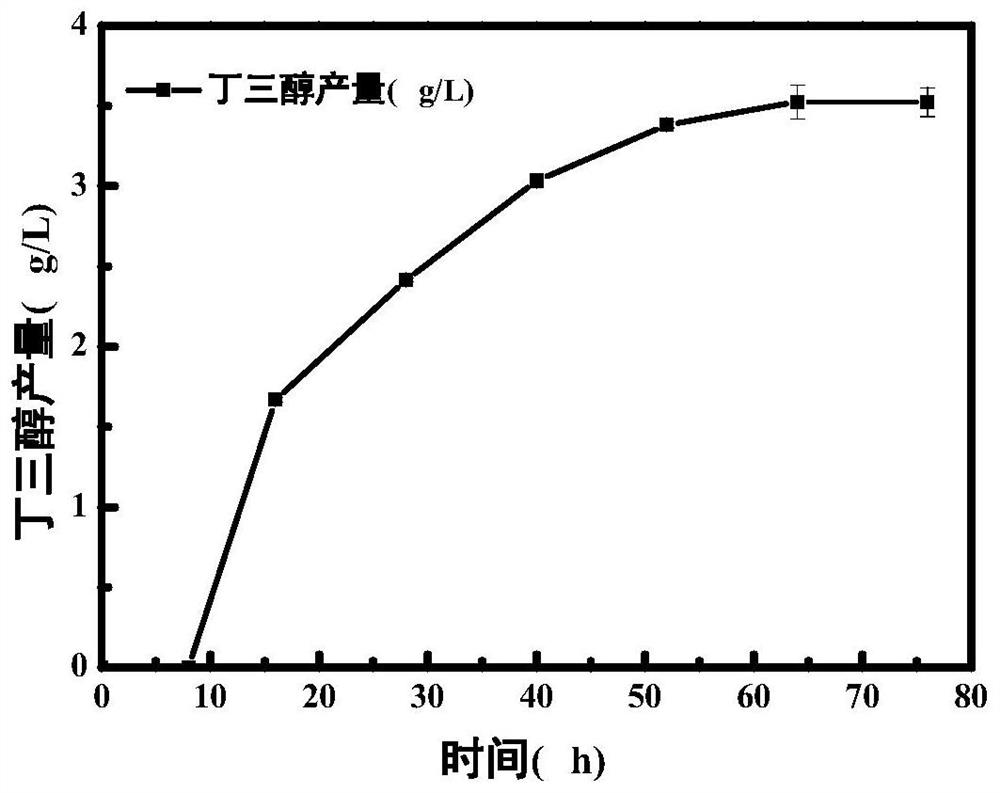

[0038] Take a group of 500ml Erlenmeyer flasks, fill them with 50ml fermentation medium containing 10g / L xylose respectively, inoculate the seed solution prepared by recombinant E. When culturing to OD600=2, add IPTG to a final concentration of 1 mmol / L. After adding IPTG, culture at 33°C for 66 hours until the end of fermentation. Samples are taken every 12 hours to measure the production of D-1,2,4-butanetriol , the result is as figure 1 . As can be seen from the figure, the production rate of the bacterial strain significantly decreased after 6...

Embodiment 3

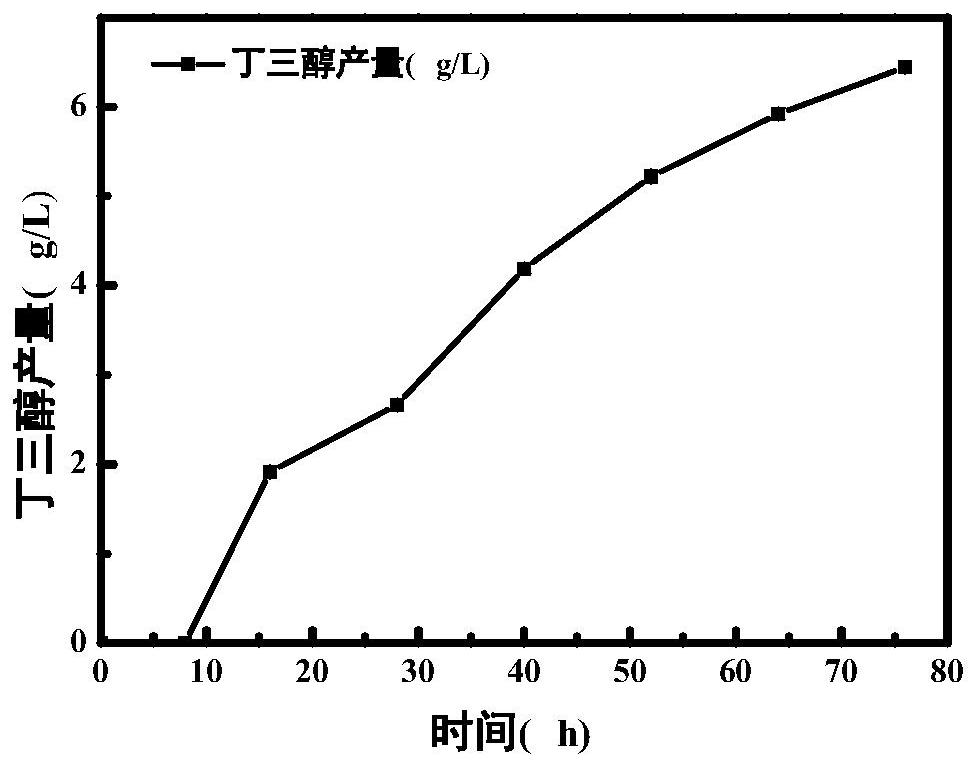

[0040] Example 3 Synchronous saccharification and fermentation of recombinant Escherichia coli using corn cob as a substrate to produce 1,2,4-butanetriol

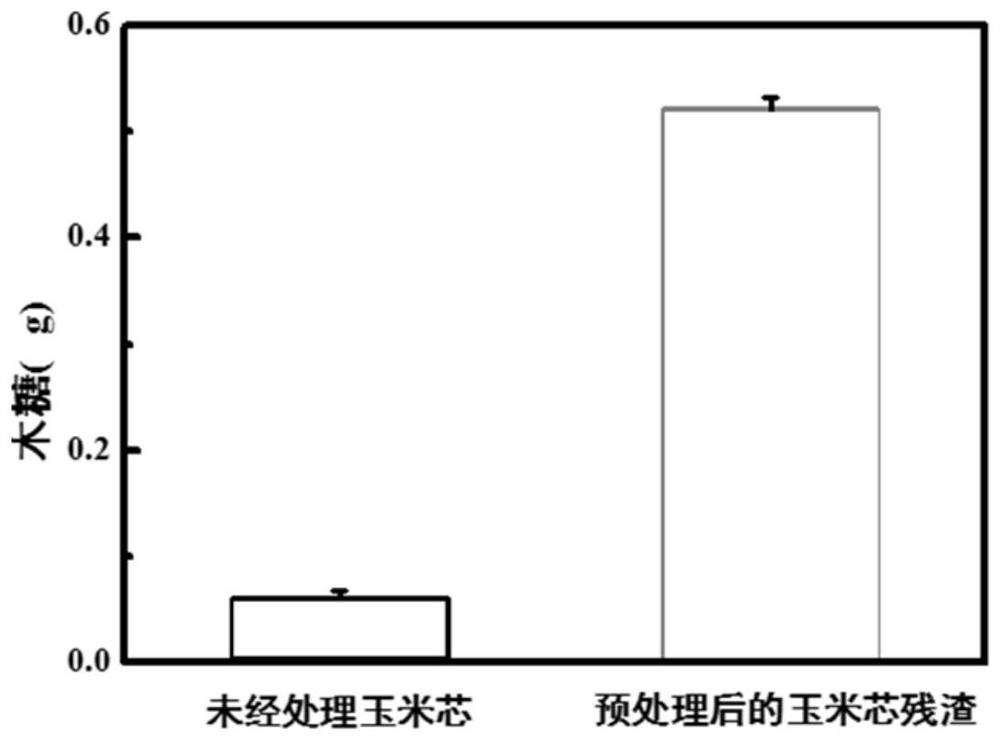

[0041] Corncobs were crushed through a 40-mesh sieve, and 1 mol / L sodium hydroxide solution and corncobs were mixed at a solid-to-liquid ratio of 10%. The mixed suspension hydrolyzate was subjected to high-temperature treatment, and the corncob residue was obtained by filtration, and the residue was washed with pure water until neutral.

[0042] Prepare LB medium with 5g / L yeast powder, 10g / L peptone, and 5g / L sodium chloride. Divide into 500mL Erlenmeyer flasks, with a liquid volume of 50mL, add 2g of pretreated corncob residue to LB medium to make a fermentation medium, and sterilize it for use.

[0043] Streak and activate the genetically engineered bacteria containing the recombinant plasmid pTRC99a-xylB-mdlC and the recombinant plasmid PCWJ-yjhG-adhP on the LB plate (streptavidin resistance and ampicillin resistance),...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap