High-air-permeability degradable drug-loaded skin wound dressing and preparation method thereof

A skin wound and air permeability technology, which is applied in the field of highly breathable and degradable drug-loaded skin wound dressing and its preparation, can solve the problems of waste of land resources, exacerbation of pain in patients, and adhesion of dressing wounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

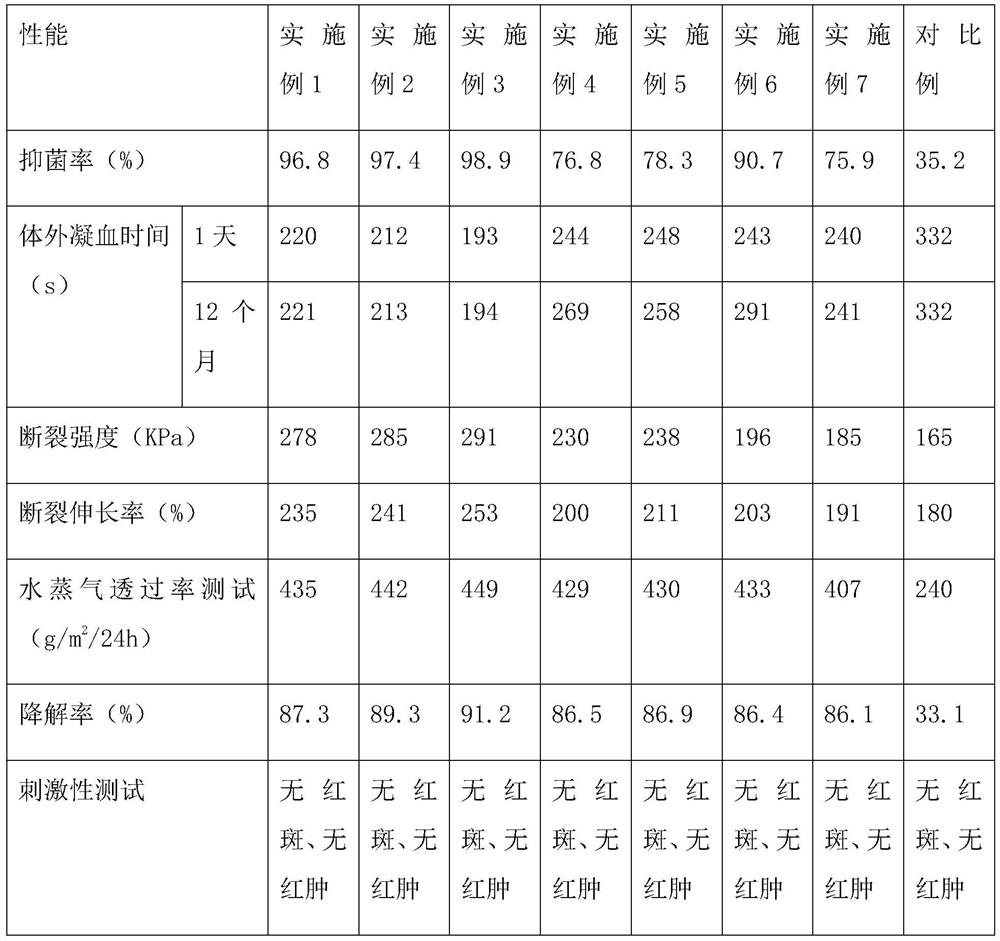

Examples

Embodiment 1

[0061] A highly breathable and degradable drug-loaded skin wound dressing, comprising a dressing inner layer, a dressing outer layer, and a repair adhesive layer; the repair adhesive layer is located between the dressing inner layer and the auxiliary material outer layer; the dressing inner layer is The inner layer spinning solution is obtained by electrospinning, and the outer layer of the dressing is obtained by subjecting the outer layer spinning solution to electrospinning.

[0062] The repair glue layer includes the following raw material components: in parts by weight, 80 parts of porous drug-loaded microspheres, 30 parts of dialdehyde pectin, 30 parts of pullulan, 40 parts of o-aminobenzyl chloride, 15 parts of dopamine, 35 parts of hydroxycucurbitan; the thickness of the repair adhesive layer is 1 μm.

[0063] The inner layer spinning solution includes the following raw material components: in parts by weight, 10 parts of polyvinylidene fluoride, 600 parts of gelatin, ...

Embodiment 2

[0083]A highly breathable and degradable drug-loaded skin wound dressing, comprising a dressing inner layer, a dressing outer layer, and a repair adhesive layer; the repair adhesive layer is located between the dressing inner layer and the auxiliary material outer layer; the dressing inner layer is The inner layer spinning solution is obtained by electrospinning, and the outer layer of the dressing is obtained by subjecting the outer layer spinning solution to electrospinning.

[0084] The repair glue layer includes the following raw material components: in parts by weight, 90 parts of porous drug-loaded microspheres, 45 parts of dialdehyde pectin, 45 parts of pullulan, 45 parts of o-aminobenzyl chloride, 25 parts of dopamine, 40 parts of hydroxycucurbitan; the thickness of the repair adhesive layer is 25 μm.

[0085] The inner layer spinning solution includes the following raw material components: in parts by weight, 20 parts of polyvinylidene fluoride, 80 parts of gelatin, 7...

Embodiment 3

[0105] A highly breathable and degradable drug-loaded skin wound dressing, comprising a dressing inner layer, a dressing outer layer, and a repair adhesive layer; the repair adhesive layer is located between the dressing inner layer and the auxiliary material outer layer; the dressing inner layer is The inner layer spinning solution is obtained by electrospinning, and the outer layer of the dressing is obtained by subjecting the outer layer spinning solution to electrospinning.

[0106] The repair glue layer includes the following raw material components: in parts by weight, 100 parts of porous drug-loaded microspheres, 60 parts of dialdehyde pectin, 60 parts of pullulan, 50 parts of o-aminobenzyl chloride, 35 parts of dopamine, 45 parts of hydroxycucurbitan; the thickness of the repair adhesive layer is 50 μm.

[0107] The inner layer spinning solution includes the following raw material components: in parts by weight, 30 parts of polyvinylidene fluoride, 100 parts of gelatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com