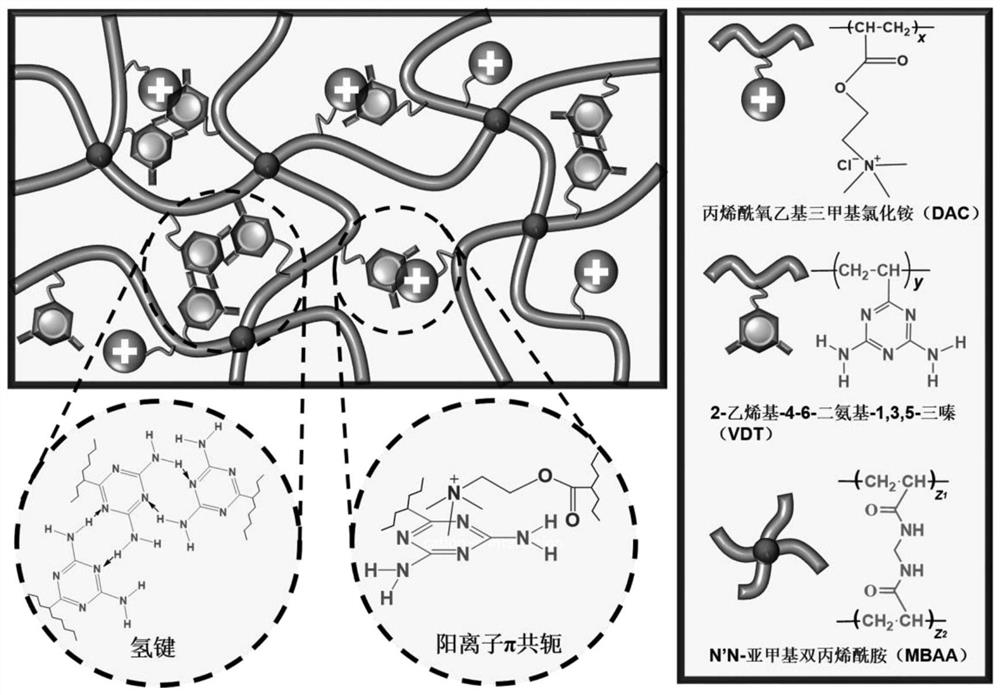

High-adhesion composite hydrogel with synergism between strong hydrogen bonds and cation-pi interaction, and preparation method thereof

A composite hydrogel and cation technology, which is applied in the fields of pharmaceutical formulation, coating, and medical science, can solve the problems of complex operation, common method of high adhesion of difficult hydrogel, etc., and achieve simple preparation process, excellent adhesion With the effect of simple performance and process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Step 1): Weigh DAC, VDT, MBAA, and KA and dissolve them in 10 mL of dimethyl sulfoxide, and stir in a water bath at 70°C for 30 min under light-shielding conditions to obtain a uniform mixed solution, so that in the obtained mixed solution, DAC The concentration is 315 mg / mL, the VDT is 151 mg / mL, the molar weight of MBAA accounts for 0.5% of the total molar amount of the monomers, and the molar amount of KA accounts for 0.25% of the total molar amounts of the monomers.

[0024] Step 2): inject the mixed solution obtained in step 1) into a glass mold under light-shielding conditions, and place it under an ultraviolet light for 12 hours to obtain a strong hydrogen bond and cation π synergistic high-adhesion composite hydrogel film.

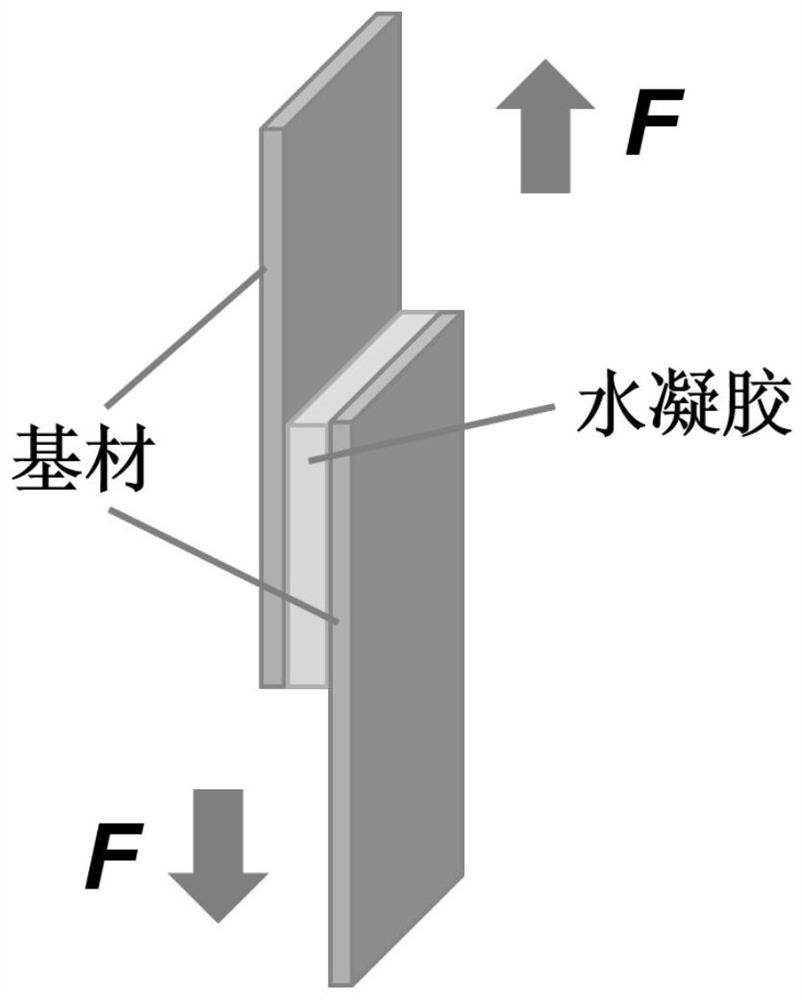

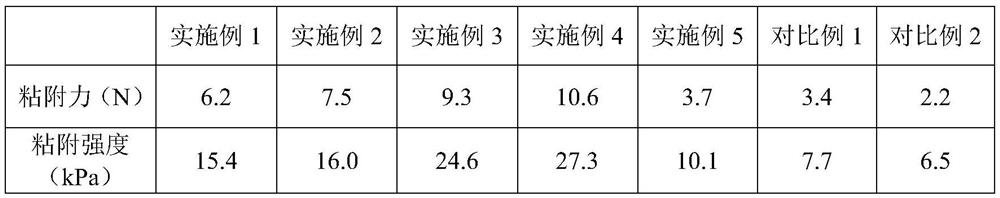

[0025] The hydrogel material obtained in this embodiment and the glass press figure 2 For the lap joint shown, the adhesion force is 6.2N and the adhesion strength is 15.4kPa as measured by the adhesion shear strength test using an electron...

Embodiment 2

[0027] Step 1): Weigh DAC, VDT, MBAA, and KA and dissolve them in 10 mL of dimethyl sulfoxide, and stir in a water bath at 70°C for 30 min under light-shielding conditions to obtain a uniform mixed solution, so that in the obtained mixed solution, DAC The concentration is 291 mg / mL, the VDT is 156 mg / mL, the molar weight of MBAA accounts for 0.1% of the total molar amount of the monomers, and the molar amount of KA accounts for 0.25% of the total molar amounts of the monomers.

[0028] Step 2): inject the mixed solution obtained in step 1) into a glass mold under light-shielding conditions, and place it under an ultraviolet light for 12 hours to obtain a strong hydrogen bond and cation π synergistic high-adhesion composite hydrogel film.

[0029] The hydrogel material obtained in this embodiment and the glass press figure 2 For the lap joint shown, the adhesion force is 7.8N and the adhesion strength is 17.3kPa as measured by the adhesion shear strength test using an electron...

Embodiment 3

[0031] Step 1): Weigh DAC, VDT, MBAA, and KA and dissolve them in 10 mL of dimethyl sulfoxide, and stir in a water bath at 70°C for 30 min under light-shielding conditions to obtain a uniform mixed solution, so that in the obtained mixed solution, DAC The concentration is 291 mg / mL, the VDT is 156 mg / mL, the molar weight of MBAA accounts for 0.5% of the total molar amount of the monomers, and the molar weight of KA accounts for 0.25% of the total molar amounts of the monomers.

[0032] Step 2): inject the mixed solution obtained in step 1) into a glass mold under light-shielding conditions, and place it under an ultraviolet light for 12 hours to obtain a strong hydrogen bond and cation π synergistic high-adhesion composite hydrogel film.

[0033] The hydrogel material obtained in this embodiment and the glass press figure 2 For the lap joint shown, the adhesion force is 9.3N and the adhesion strength is 24.6kPa as measured by the adhesion shear strength test using an electron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com