Lithium battery positive electrode material molybdenum doping method

A positive electrode material and lithium battery technology, applied in the field of metallurgical electrode materials, can solve the problems that the method of doping molybdenum cannot satisfy low energy consumption and uniform diffusion at the same time, and achieve the effects of improving processing performance and electrical performance, easy crushing, and increased gram capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

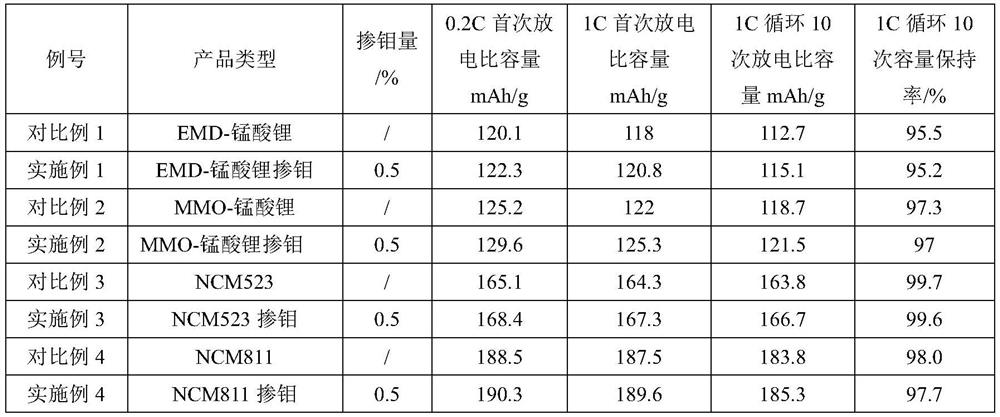

Examples

Embodiment 1

[0030] Lithium manganate product example 1: Lithium manganate doped with 0.5% molybdenum was synthesized by electrolytic manganese dioxide.

[0031] (1) preparation concentration is the lithium molybdate solution of 1.8mol / L; Get the electrolytic manganese dioxide 800Kg that particle size D50 is 16 μ m, add lithium carbonate by the lithium manganese ratio of 0.54, put into the oblique mixer that volume is 2.5 cubic meters Mix for 2 hours; add 22.6 L of the prepared lithium molybdate solution and continue mixing for 0.5 hours. After testing, a mixture with a water content of 2.8% is obtained.

[0032] (2) Put the wet material into the sagger, control the thickness of the material layer in the sagger to 6 cm, the material enters the roller kiln with the sagger, control the temperature rise rate of the heating section of the roller kiln to 5°C / min, and the material passes through 800°C After roasting for 15 hours, it is cooled to about 100°C for 6 hours and released from the furn...

Embodiment 2

[0038] Lithium manganate product example 2: Synthesize lithium manganate doped with 0.5% molybdenum with spherical trimanganese tetraoxide.

[0039] (1) Prepare a lithium molybdate solution with a concentration of 1.8mol / L. Take 800Kg of spherical trimanganese tetraoxide with particle size D50 of 10 μm, add industrial grade lithium carbonate according to the ratio of lithium to manganese of 0.54, put it into an oblique mixer with a volume of 2.5 cubic meters and mix for 2 hours; add the prepared lithium molybdate solution 26.7 L and continue mixing 0.5 hour, after testing, obtain the mixing material that moisture content is 2.5%;

[0040] (2) Put the wet material into the sagger, control the thickness of the material layer in the sagger to 5 cm, the material enters the roller kiln with the sagger, control the temperature rise rate of the heating section of the roller kiln to 5°C / min, and the material passes through 770°C After roasting for 12 hours, it is cooled to about 100°...

Embodiment 3

[0046] Example 3 of 523 ternary product: 523 ternary cathode material doped with 0.5% molybdenum was synthesized by using 523 ternary precursor.

[0047] (1) Prepare a lithium molybdate solution with a concentration of 1.8mol / L. Take 90g of 523 ternary precursor whose particle size D50 is 10 μm, add lithium carbonate according to the ratio of Li:M=1.02, put it into a ball mill tank and mix for 2 hours; add 2.74ml of prepared lithium molybdate solution and continue mixing for 0.5 hours After testing, a mixture with a moisture content of 2.0% was obtained;

[0048] (2) Put the wet material into the sagger, and the material enters the atmosphere furnace with the sagger, and the heating rate of the heating section is controlled to be 5°C / min. The material is roasted at 830°C for 12 hours, and then cooled to about 100°C for 6 hours before being released from the furnace. The material in the sagger is agglomerated but easily crushed, and then crushed and sieved to obtain a 523 ternar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com