Preparation and application of chitosan-stabilized ferrous sulfide composite biochar material

A technology of ferrous sulfide and biochar, applied in the field of environmental restoration, can solve problems such as dioxins that cannot meet the emission standards and environmental threats

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: material preparation

[0029] 1) Preparation of biochar: crush the cleaned and dried highland barley stalks, pass through a 40-mesh standard sieve for later use. Measure 50mL of 98% concentrated sulfuric acid into a 250mL round bottom flask, add 65g of highland barley straw powder, add 1.3g of asphalt, raise the temperature to 200°C, keep it for 2h, after cooling to room temperature, add deionized water, and stir for 15min Filtrate, wash and filter repeatedly until the filter residue has a pH value of 7, put it in a vacuum drying oven, set the temperature at 150°C, dry for 16 hours, and pass through a 100-mesh standard sieve to obtain biochar.

[0030] 2) Preparation of FeS: Weigh 3.1591g FeSO 4 ·7H 2 O was dissolved in 50mL of deionized water, stirred on a magnetic stirrer for 30min, and weighed 2.7273gNa 2 S·9H 2 O was dissolved in 30mL of deionized water, sonicated with an ultrasonic cleaner for 15min to make it completely dissolved, then transferre...

Embodiment 2

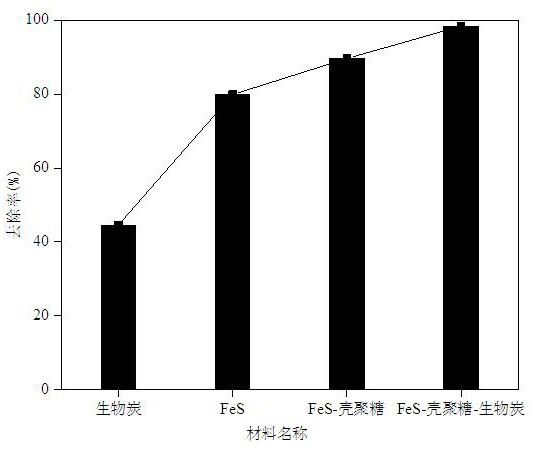

[0033] Example 2: Comparative experiment on the effect of different materials to remove Cr(Ⅵ)

[0034] Weigh 0.1g of biochar, FeS, FeS-chitosan, and FeS-chitosan-biochar, respectively, and add them to 50mL of simulated wastewater with an initial chromium concentration of 100mg / L, seal and place in a water bath with a constant temperature of 25°C In the shaker, samples were taken for analysis after 24 hours of reaction, and the experiment was set up for parallel experiments. The comparison of the removal rate obtained by analysis and calculation is as followsfigure 1 shown.

Embodiment 3

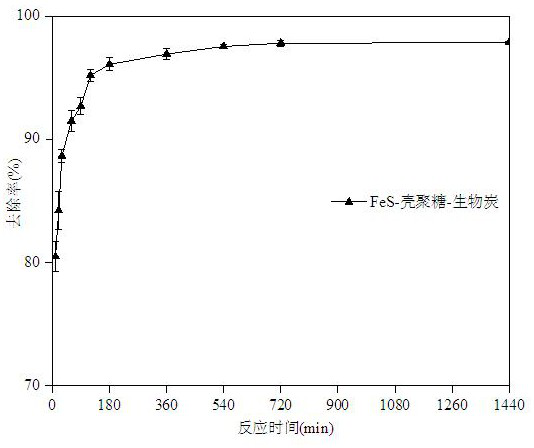

[0035] Example 3: Experiment of the Cr(Ⅵ) removal rate of FeS-chitosan-biochar as a function of time

[0036] Weigh 0.1 g of FeS-chitosan-biochar, add it to 50 mL of simulated wastewater with an initial chromium concentration of 100 mg / L, seal it and place it in a constant temperature 25°C water bath shaker, and react at 10, 20, 30, After 60, 90, 120, 180, 360, 540, 720, and 1440 minutes, samples were taken for analysis, and the experiments were set up for parallel experiments. The removal rate obtained by analysis and calculation changes with time as figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com