Anaerobic microorganism culture medium deoxygenization device capable of adjusting gas composition and deoxygenization method

A technology composed of anaerobic microorganisms and gases, applied in enzymatic/microbiology devices, biochemical cleaning devices, biochemical equipment and methods, etc. Complex operation and other problems, to achieve the effect of simplifying the experimental operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

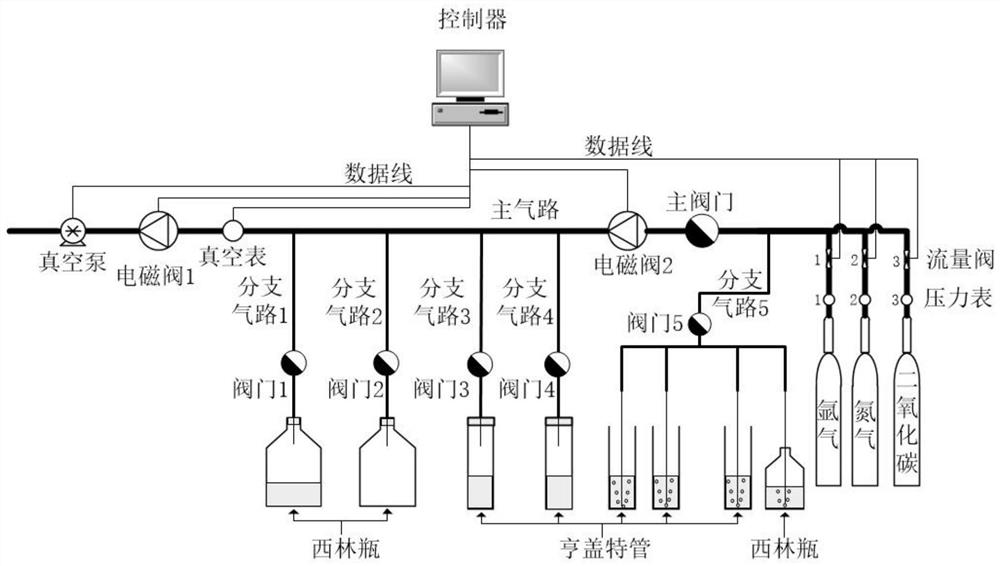

[0035] This embodiment provides an oxygen removal device for anaerobic microorganism culture medium whose gas composition can be adjusted, and its gas circuit structure is as follows: figure 1 shown.

[0036] The anaerobic microbial culture medium deoxygenation device with adjustable gas composition includes a system controller, a pressure gauge, a gas flow valve, a solenoid valve, a vacuum gauge, a vacuum pump, an air system and valves, and its structure is as follows:

[0037] The gas circuit system is composed of a main gas circuit and a plurality of branch gas circuits. One end of the main gas circuit is a vacuum pump, and the other end of the vacuum pump is connected to the outside atmosphere. The vacuum pump is used to pump out the gas in the gas circuit. The other end of the vacuum pump is connected to an electromagnetic valve 1 through an air pipeline, and the other end of the electromagnetic valve 1 is provided with a vacuum gauge for detecting the vacuum degree of th...

Embodiment 2

[0049] Such as Figure 4~7 As shown, the gas circuit system according to Embodiment 1 provides an automatic anaerobic microorganism preparation device, including a main gas circuit 211, a box body 230 and a controller 232, and the upper surface of the box body 230 is detachably connected with a support ring 231, The lower surface inside the box body 230 is fixedly connected with a bottom plate 222, and the inside of the bottom plate 222 is placed with a main air circuit 211, and the right side of the main air circuit 211 is connected with a vacuum gauge 212, a solenoid valve 1 214 and a vacuum pump 216 in sequence from front to back, and the vacuum pump 216 is placed on the right side of the upper surface of the bottom plate 222, and the bottom of the main gas path 211 is connected to the left side of the vacuum gauge 212 with a branch gas path 1 227, a valve 2 204, a branch gas path 3 208 and a branch gas path 4 213, and the branch There is a valve four 215 connected between ...

Embodiment 4

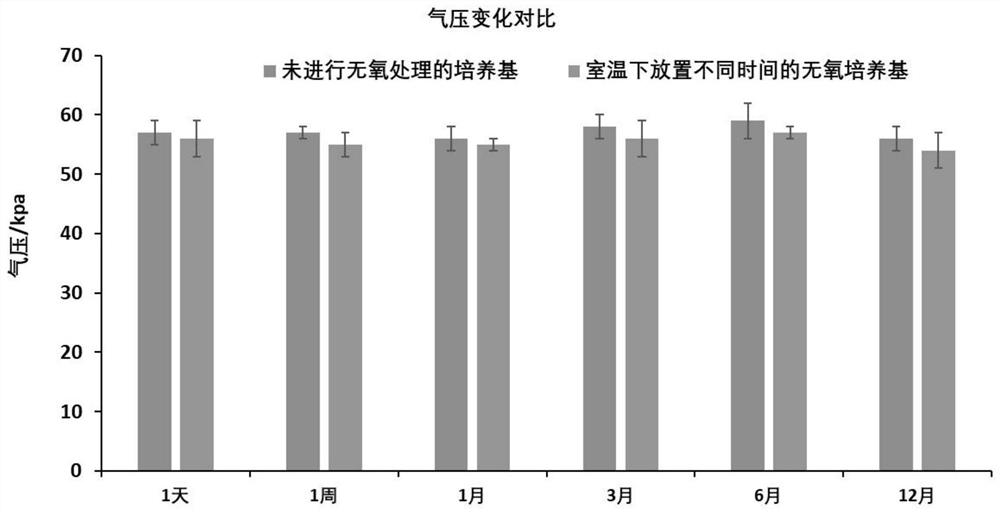

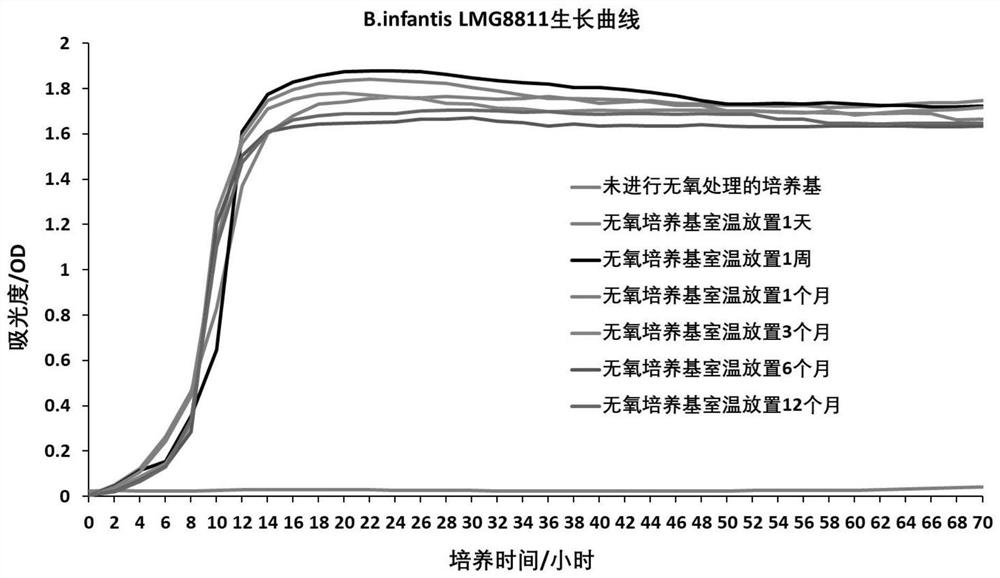

[0056] Bifidobacteria are strictly anaerobic bacteria, even if there is a trace amount of residual oxygen in the culture environment, Bifidobacteria cannot grow. In this example, high-purity nitrogen is used to create an anaerobic environment for the growth of bifidobacteria. In combination with Figures 1 to 3, the specific operation process is as follows:

[0057] Accurately weigh 38g of enhanced Clostridium medium (RCM) (purchased from Merck, Germany), dissolve it in 1000mL of distilled water with heating and stirring, and after the RCM medium is completely dissolved, dispense it into a 30mL Hungate tube. Every Hengate tube is filled with 10mL RCM culture medium solution, then uses the anaerobic microbial culture medium deoxygenation device that can adjust the gas composition in the present invention, the substratum in the Hengate tube is aerated, during aeration Insert the 30 cm long needles connected to the branch gas path 5 into the bottom of the Hengate tube respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com