Preparation method and application of high-efficiency seawater full electrolysis catalyst for hydrogen phosphide production

A phosphide and catalyst technology, which is applied in the field of preparation of hydrogen phosphide catalysts for high-efficiency full electrolysis of seawater, can solve problems such as corrosion of production equipment, hindrance of full contact between electrodes and electrolyte, and chlorine gas as a side reaction of chlorine analysis, so as to reduce corrosion, The effect of excellent oxygen evolution selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Step 1. Add ferric nitrate (81mg, 0.2mmol), nickel nitrate (175mg, 0.6mmol), ammonium molybdate (124mg, 0.1mmol), urea (240mg, 4mmol) and ammonium fluoride (59mg, 1.6mmol) in sequence In a stirrer filled with 40 mL of deionized water, stir evenly for 10 min, and set the speed of the stirrer at 500 r / min. After the mixture is fully dissolved, transfer the mixed solution to a 50 mL hydrothermal kettle.

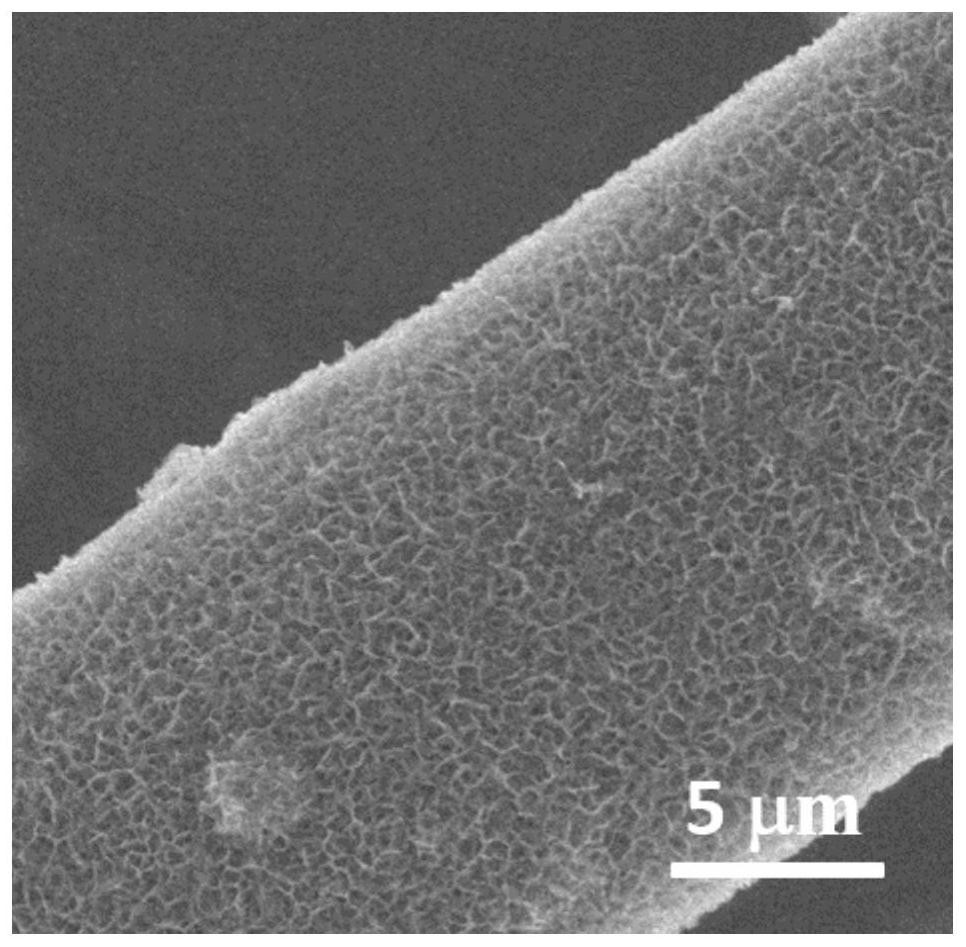

[0017] Step 2. Take carbon fiber paper with a length of 3 cm and a width of 2 cm and place it in the hydrothermal kettle of step 1. After ultrasonic treatment for 7 minutes, conduct a hydrothermal reaction at a temperature of 120 ° C. The reaction time is controlled at 12 hours. After the reaction is completed, The carbon fiber paper was taken out, rinsed repeatedly with deionized water 4 times, and dried in a vacuum drying oven for 12 h at a temperature of 60 °C to obtain a NiFeMo@CFP sample. Its scanning electron microscope image, such as figure 1 As shown, the NiFeMo ...

Embodiment 2

[0020] Step 1. Add ferric nitrate (81mg, 0.2mmol), nickel nitrate (350mg, 1.2mmol), ammonium molybdate (124mg, 0.1mmol), urea (240mg, 4mmol) and ammonium fluoride (59mg, 1.6mmol) in sequence In a stirrer filled with 40 mL of deionized water, stir evenly for 10 min, and set the speed of the stirrer at 300 r / min. After the mixture is fully dissolved, transfer the mixed solution to a 50 mL hydrothermal kettle.

[0021] Step 2. Take carbon fiber paper with a length of 3 cm and a width of 2 cm and place it in the hydrothermal kettle of step 1. After ultrasonic treatment for 10 minutes, conduct a hydrothermal reaction at a temperature of 160 ° C. The reaction time is controlled at 18 hours. After the reaction is completed, The carbon fiber paper was taken out, rinsed repeatedly with deionized water 4 times, and dried in a vacuum drying oven for 12 h at a temperature of 60 °C to obtain a NiFeMo@CFP sample.

[0022] Step 3. Weigh 120 mg of sodium hypophosphite and place it upstream of...

Embodiment 3

[0024] Step 1. Add ferric nitrate (81mg, 0.2mmol), nickel nitrate (175mg, 0.6mmol), ammonium molybdate (500mg, 0.4mmol), urea (240mg, 4mmol) and ammonium fluoride (59mg, 1.6mmol) in sequence In a stirrer filled with 40mL of deionized water, stir evenly for 8min, and set the speed of the stirrer at 700r / min. After the mixture is fully dissolved, transfer the mixed solution to a 50mL hydrothermal kettle.

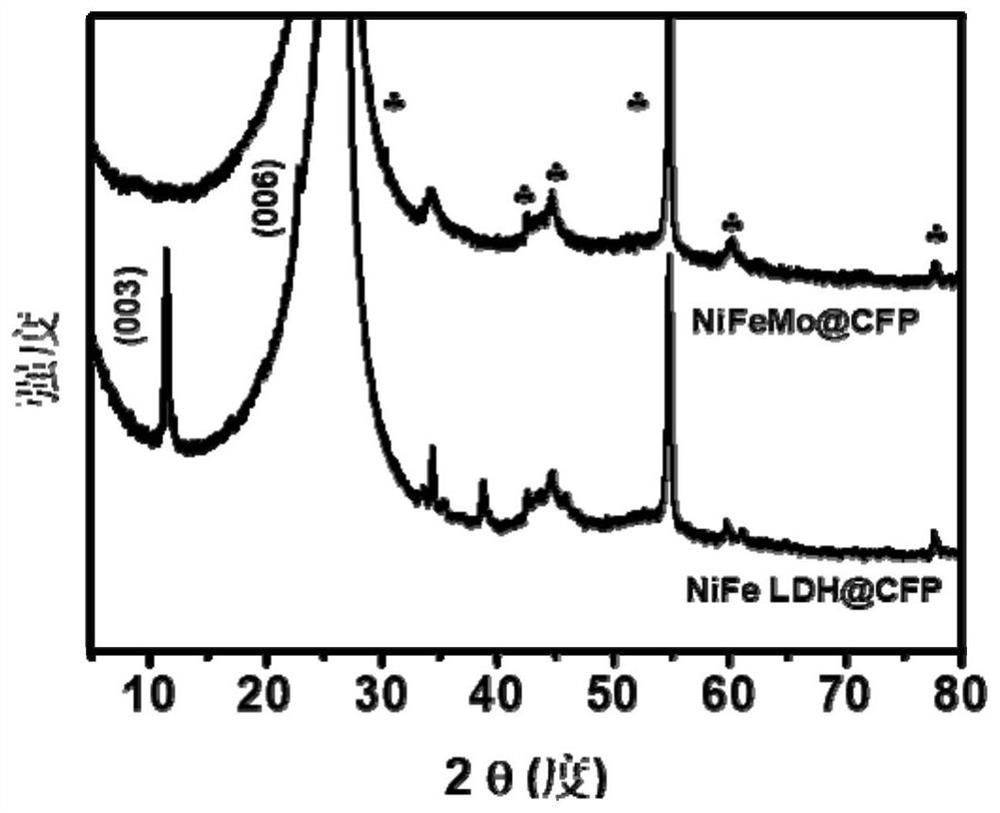

[0025] Step 2. Take carbon fiber paper with a length of 4 cm and a width of 2 cm and place it in the hydrothermal kettle of step 1. After ultrasonic treatment for 8 minutes, conduct a hydrothermal reaction at a temperature of 120°C. The reaction time is controlled at 12 hours. After the reaction is completed, The carbon fiber paper was taken out, rinsed repeatedly with deionized water four times, and dried in a vacuum drying oven for 12 hours at a temperature of 80 °C to obtain a NiFeMo@CFP sample. XRD spectrum, such as figure 2 As shown, it can be seen that Mo 6+ After the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com