MOFs/water hyacinth derivative material, preparation method thereof and degradation method of organic pollutants

A technology for water hyacinth and organic matter, which is applied in the fields of water pollutants, organic compounds/hydrides/coordination complex catalysts, water/sewage treatment, etc., can solve the problems of water pollution, crystal growth, metal ion leaching, etc. High utilization rate, overcoming the effects of easy agglomeration and excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Weigh 1mmol Co(NO 3 ) 2 ·6H 2 0 and 5mmol 2-methylimidazole are dissolved in 60mL methanol respectively, mix in stirring, obtain MOFs precursor mixed solution;

[0040] (2) Weigh 20 g of 200-mesh water hyacinth biomass, add it to the MOFs precursor mixed solution, stir magnetically for 24 hours, let it stand for 24 hours, then wash the precipitate with methanol, and dry the precipitate collected by centrifugation at 65 °C , to obtain MOFs / water hyacinth precursor;

[0041](3) The dried MOFs / water hyacinth precursor was placed in a rectangular crucible and calcined in a muffle furnace to 350 °C with a heating rate of 2 °C / min and a holding time of 2 hours. The calcined samples were collected, stirred in 0.1 mol / L hydrochloric acid for 6 hours, washed with deionized water until neutral, and dried at 65°C to obtain MOFs / water hyacinth-derived materials.

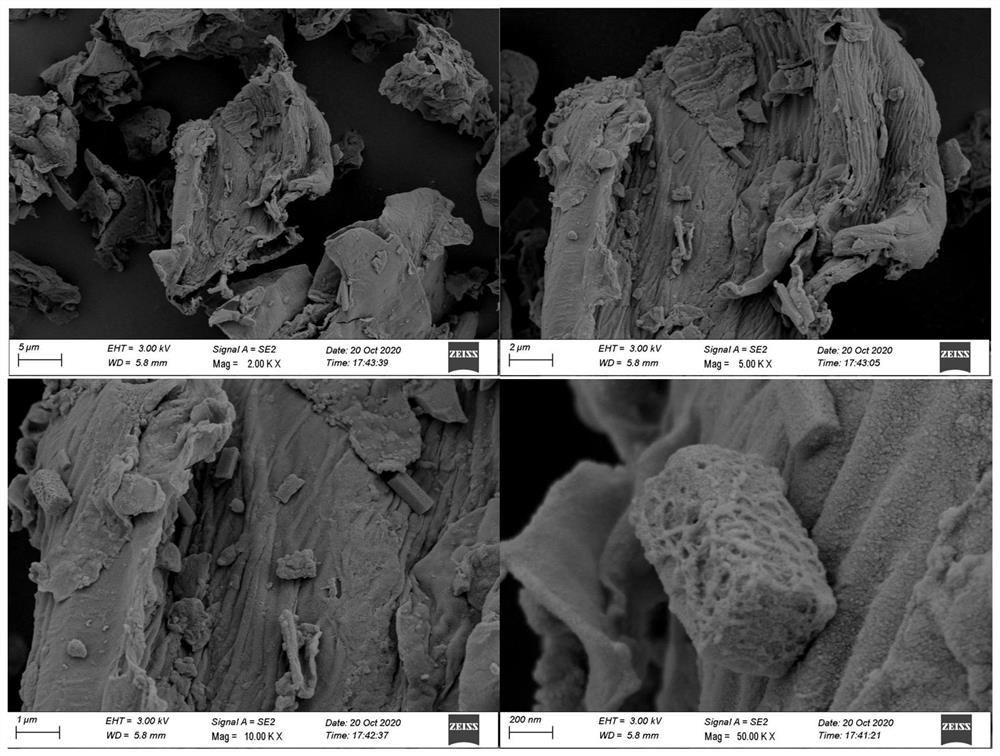

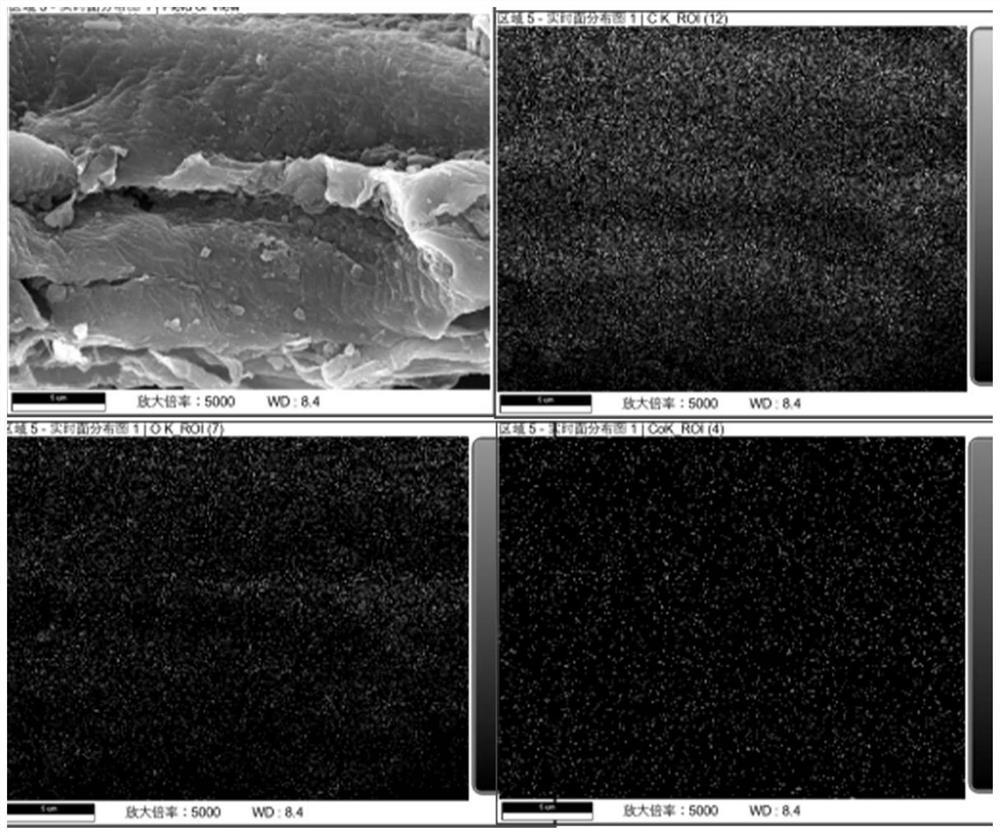

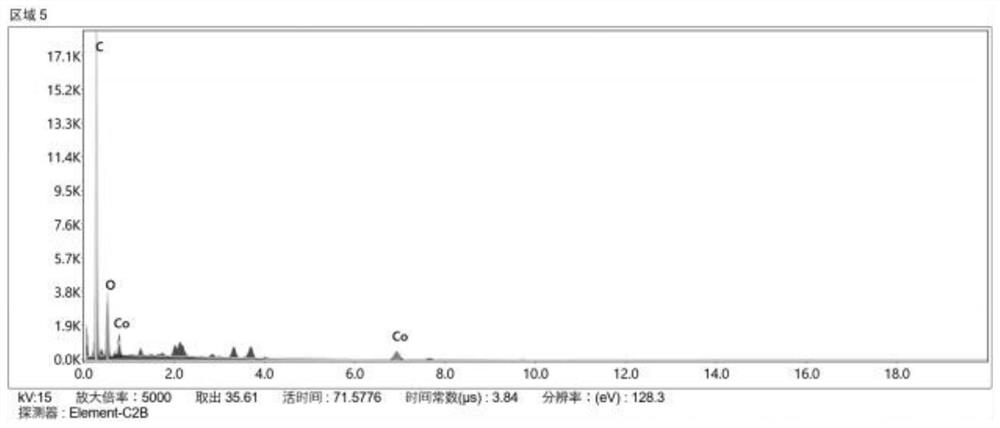

[0042] The scanning electron microscope figure of the product that the embodiment of the present application 1 ...

Embodiment 2

[0047] Pipette 100ml 20mg L -1 Put the bisphenol A solution in a 250ml Erlenmeyer flask, then add 10mg of the product obtained in Example 1 and Comparative Example 1 respectively, vibrate on a constant temperature shaker at 25°C at a speed of 180r / min, and after shaking for 60min, add 1mL of 200mmol / The LPMS solution starts the degradation reaction, samples are taken at specific time intervals, and the concentration of bisphenol A in the samples is tested after filtering with a disposable filter head. In addition, control groups using only the same amount of PMS solution and only using the same amount of MOFs / water hyacinth derived materials prepared in Example 1 to participate in the degradation were respectively set up. Take time as the abscissa, and the concentration ratio of bisphenol A before and after solution treatment as the ordinate, and draw a graph.

[0048] Figure 6 It is a comparison chart of the degradation performance of bisphenol A in Example 2 of the prese...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com