Method for preparing imidodisulfuryl fluoride through micro-channel reactor

A bisfluorosulfonimide, microchannel reactor technology, applied in chemical instruments and methods, chemical/physics/physicochemical reactors, iminodisulfonic acid/nitrilotrisulfonic acid, etc., can solve the process of Long route, equipment corrosion, unfavorable use and other problems, to achieve the effect of stable and reliable process, short reaction time and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

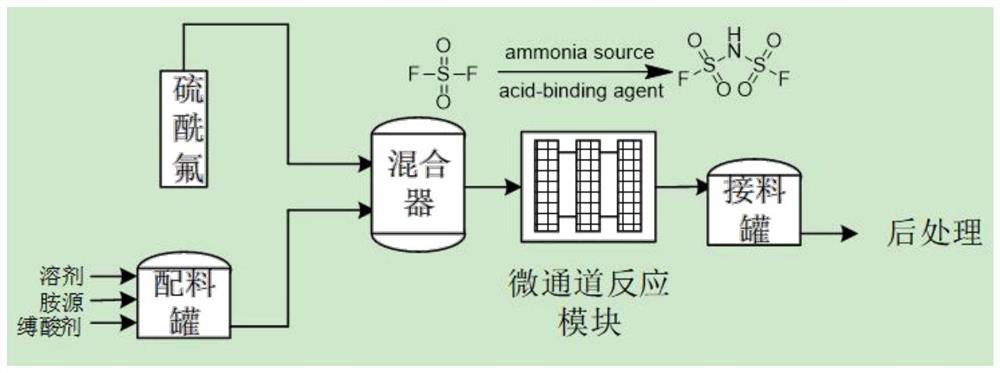

Method used

Image

Examples

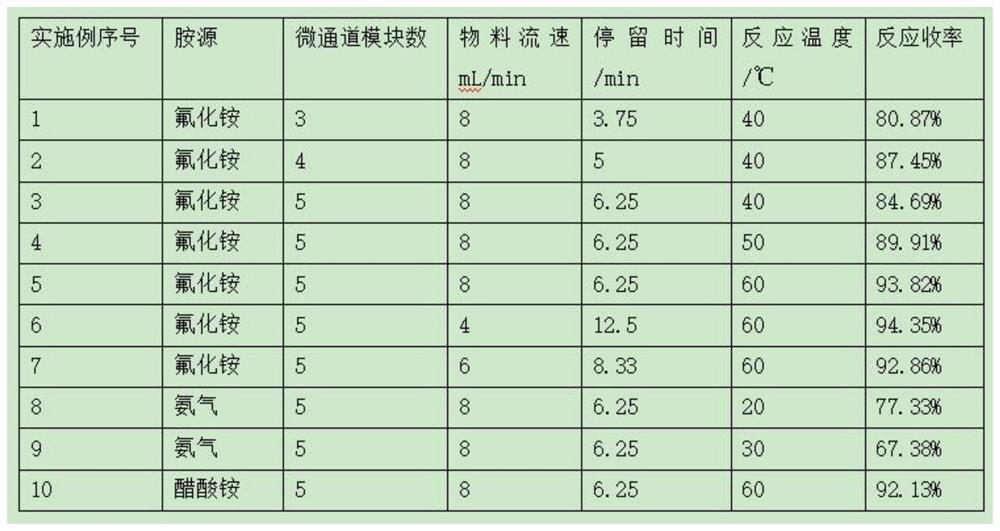

Embodiment 1

[0039] ①Add ammonium fluoride (converted according to purity), triethylamine (water content<500ppm) and methanol (water content<500ppm) into the liquid storage bottle according to the mass ratio of 1:5.465:19, and wait until the ammonium fluoride is completely dissolved , put aside;

[0040] ②Set the temperature of the high and low temperature machine at 40°C, and add methanol, triethylamine solution, and sulfuryl fluoride gas with a mass concentration of 3.93% ammonium fluoride into the mixer by a plunger pump and a gas flow meter respectively. The flow rate of 3.93% ammonium fluoride in methanol and triethylamine solution is 8mL / min, the flow rate of sulfuryl fluoride gas is 318mL / min, and the molar ratio of reactant sulfuryl fluoride: triethylamine: ammonium fluoride is 2.1:2:1;

[0041] ③The mixed solution in the premixer is injected into the microchannel of the microchannel module for reaction. There are 3 microchannel reaction modules with a liquid holding capacity of 3...

Embodiment 2

[0044] The difference from Example 1 is that there are 4 microchannel reaction modules with a liquid holding capacity of 40mL, and the reaction materials stay in the microchannel for 5min to obtain 10.72g of colorless liquid with a water content of 0.15% and a molar yield of 87.45%.

Embodiment 3

[0046] The difference from Example 1 is that there are 5 microchannel reaction modules with a liquid holding capacity of 50mL, and the reaction materials stay in the microchannel for 6.25min to obtain 10.38g of colorless liquid with a water content of 0.14% and a molar yield of 84.69%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com