Solid-waste-based porous material, preparation and method for ecological restoration of coal gangue mountain

A technology of porous materials and coal gangue, applied in the preparation of organic fertilizers, botanical equipment and methods, fertilization methods, etc., can solve problems such as difficult ecosystems, difficult growth of fungi, unfavorable plant growth, etc., and improve soil structure , Saving natural repair materials and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

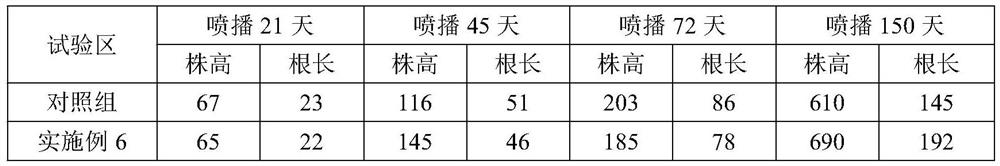

Examples

preparation example Construction

[0023] A preparation method of a solid waste-based porous material, specifically: adding coal gangue powder, fly ash, cement, desulfurized gypsum, and lime to a granulator or a sieving machine, adding a foaming agent to the water, and Water is sprayed several times, and granules of 1-8 mm are made in a granulator or a sieving machine, and solid waste-based porous materials are obtained after flue gas curing. Boiler flue gas contains carbon dioxide, sulfur dioxide, nitrogen dioxide and other acidic gases, which can be used to maintain and neutralize the alkaline substances in the material, so that the pH value of the porous granular material produced can be reduced to neutral. The temperature of the granulator or sieve is 30-50°C; the flue gas curing is specifically: the boiler flue gas and steam with a temperature above 200°C enter the curing device, and the curing temperature of the boiler flue gas and steam is 160- 200℃, the curing time is 2-6h.

[0024] A method for using ...

Embodiment 1

[0032] Embodiment 1 solid waste base porous material

[0033]60% coal gangue powder, 20% fly ash, 5% cement, 2.5% desulfurized gypsum, 12.5% lime, 0.7‰ foaming agent, 0.65 liquid-solid ratio. Foam molding for 6 hours, transfer to 160°C boiler flue gas curing for 4 hours, after drying, crush and sieve to obtain 1-8mm particles.

Embodiment 2

[0034] Example 2 solid waste based porous material

[0035] 50% of coal gangue, 30% of fly ash, 15% of cement, and 5% of desulfurized gypsum are mixed and added to the granulator, and foaming agent 1.5‰ is added to the water, and sprayed into the granulator several times according to the liquid-solid ratio of 18%. In the process, 3-8mm particles were made, and the foaming was stopped at 50°C for 6 hours, and then cured at 160°C for 6 hours to obtain non-fired porous particle materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com