Heat-resistant degradable plastic and preparation method thereof

A technology for degrading plastics and heat resistance, which is applied in the field of heat-resistant degradable plastics and its preparation, and can solve distortion, inorganic filler dispersion, poor compatibility, mechanical properties and heat resistance, and poor heat resistance of degradable plastic products and other problems, to achieve the effect of reducing internal stress, reducing interface effects and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

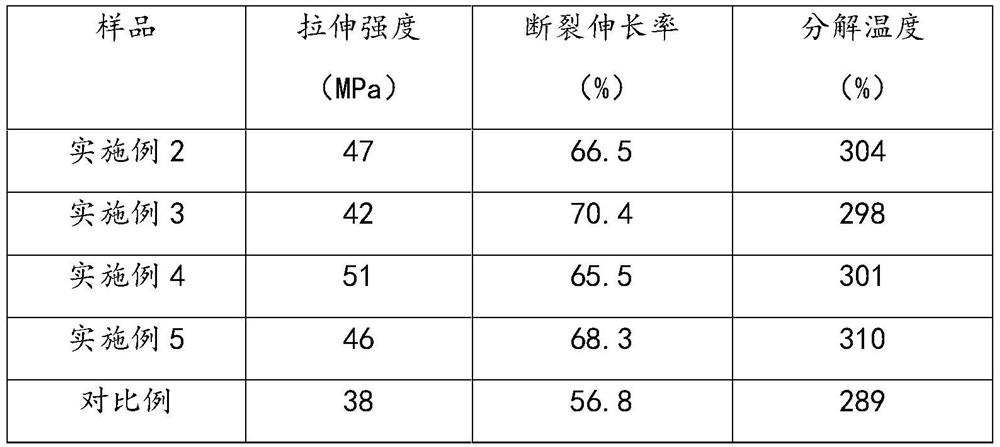

Examples

preparation example Construction

[0016] 1. Preparation of modified nano-silica particles

[0017] The modified silica nanoparticles are chitosan modified silica nanoparticles. Because a large number of hydrogen bonds can be formed between chitosan and silicon dioxide, composite nanoparticles with a porous structure on the surface can be made by using the reverse microemulsion method. The specific preparation example is as follows:

Embodiment 1

[0019] The present embodiment provides a kind of preparation method of modified chitosan modified nano silicon dioxide particle, and concrete steps are as follows:

[0020] (1) Mix 800 L of cyclohexane, 200 L of surfactant polyethylene glycol octyl phenyl ether (Triton X-100) and 200 L of co-surfactant n-hexanol, add 50 L of double distilled water, stir vigorously for 5 minutes, and then oil Water-encapsulated microemulsions;

[0021] (2) Add chitosan solution (5%, 100L) to the above-mentioned microemulsion, add sodium hydroxide to adjust the pH value to neutrality, then add tetraethyl orthosilicate 100kg, ammoniacal liquor 20kg in the microemulsion successively, After stirring evenly, continue to stir and react for 24;

[0022] (3) After the reaction in step (2) is completed, add 500L of acetone for demulsification. After demulsification, nanoparticles are separated from the microemulsion. After centrifugation, the obtained particles are washed with 100L of acetone, 100L of ...

Embodiment 2

[0025] This embodiment provides a heat-resistant and degradable plastic, which includes the following composition: 42 parts of polyvinyl alcohol, 18 parts of polydibutyl succinate, 30 parts of corn starch, 2 parts of urea, 25 parts of modified silica nanoparticles 3 parts, epoxy resin 3 parts;

[0026] The preparation method of the heat-resistant and degradable plastics comprises weighing 250 g of modified silicon dioxide nanoparticles, 420 g of polyvinyl alcohol, 180 g of poly(dibutyl succinate), 300 g of corn starch, 20 g of urea, and 30 g of epoxy resin, and then adding Fully mix and react in a high-speed mixer, and keep the mixing temperature at 85°C. After reacting for 2 hours, extrude and granulate through a twin-screw extruder to obtain degradable plastic masterbatches.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com