High-dielectric elastic composite material as well as preparation method and application thereof

An elastic composite material, high dielectric technology, applied in chemical instruments and methods, electrospinning, rayon manufacturing, etc., can solve problems such as difficulty in achieving mechanical flexibility, and achieve the effect of optimizing dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0077] 2) The in-situ composite preparation method of the present invention realizes the self-assembly design of various polymer materials and inorganic nanomaterials. This process provides the basis for the orderly design of microstructures, and at the same time realizes the large-area preparation of composite films.

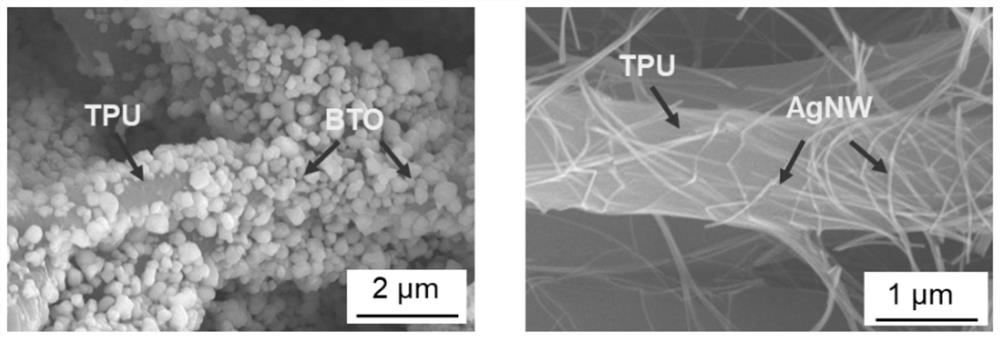

[0078] 3) The in-situ composite process of the present invention overcomes the difficulty of dispersing inorganic nanomaterials in high-viscosity polymer materials, avoids the agglomeration of nanomaterials, and can regulate the distribution of nanomaterials in an orderly manner.

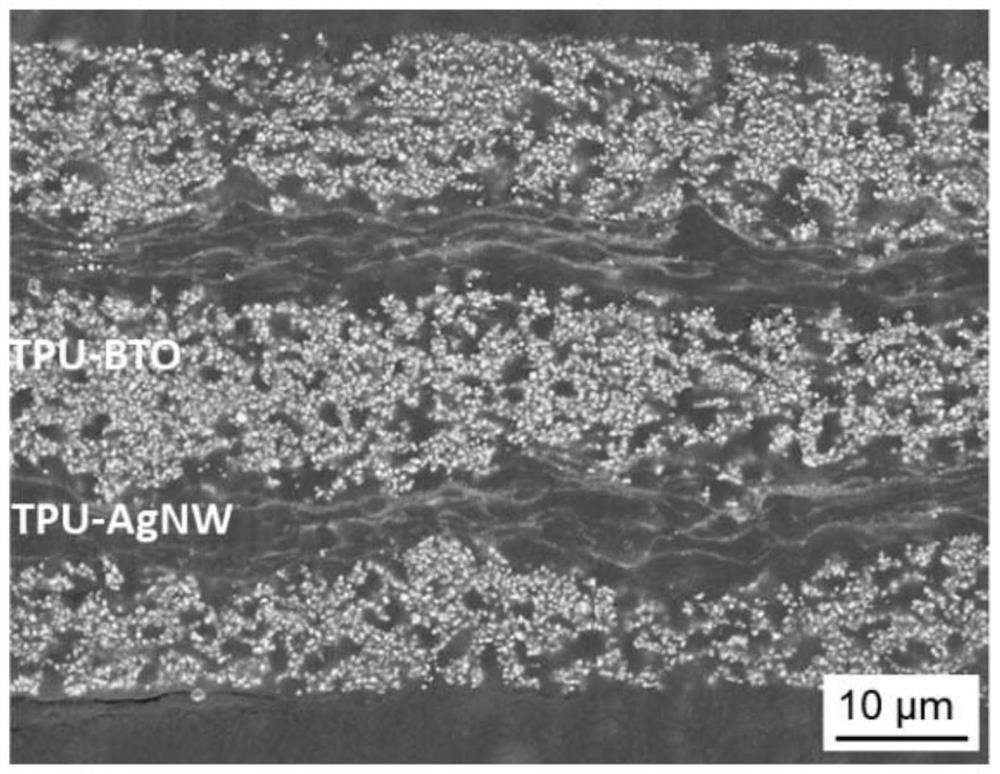

[0079] 4) The present invention has prepared the elastic composite film that the ceramic nanomaterial is distributed in three-dimensional network structure in the elastic matrix, and the aggregation network structure of nanoparticles in the polymer enhances its dipole polarization effect under the electric field, which is beneficial to improve the composite material the dielectric con...

Embodiment 1

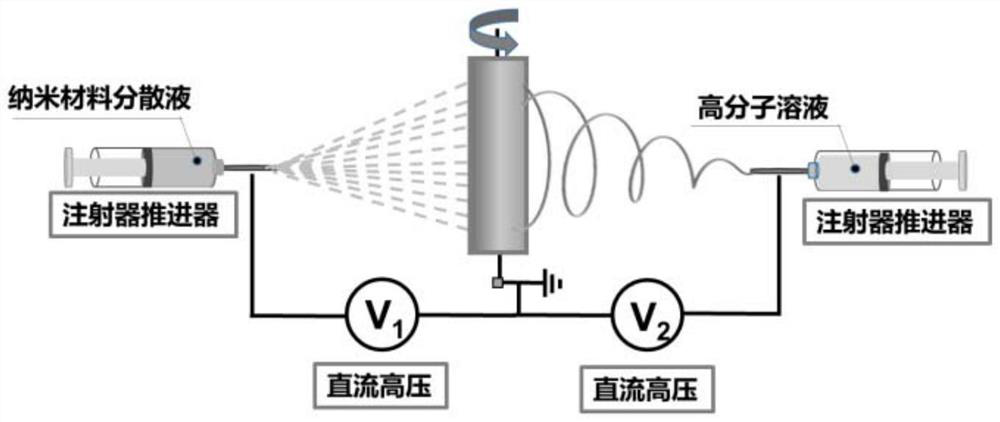

[0095] In this embodiment, a rapid non-equilibrium preparation method of in-situ compounding is adopted, and by means of a high-voltage electric field, the in-situ assembly of active nanomaterials in the process of forming polymer fibers is realized to form a continuous network. Combined with the hot pressing process, the stacked and assembled heterogeneous films are prepared into a dense and integrated elastic composite film, which realizes uniform and stable preparation of elastic composite materials.

[0096] Specific steps are as follows:

[0097] (1) Adopting hexafluoroisopropanol as solvent, the preparation mass fraction is 4% polyurethane (TPU, BASF 1180A) solution was magnetically stirred at room temperature for 6 hours to obtain a clear and transparent solution.

[0098] (2) Disperse the dried barium titanate (BTO) nanoparticles (nanoparticle diameter is 300nm) in absolute ethanol solution, the concentration of BTO is 0.1g / ml, initially use magnetic stirring for 10m...

Embodiment 2

[0109] Fabrication and testing of flexible strain sensors based on elastic composite materials:

[0110] (1) An elastic conductive film with AgNW uniformly distributed in the TPU fiber network was prepared by in-situ composite method. On the double injection electrospinning instrument, one end spins the TPU solution, the spinning voltage is 10kV, the injection speed is 0.2mm / min, and the spinning distance is 17cm; the other end carries out synchronous electrostatic spraying of the AgNW dispersion, and the spraying voltage is 12kV , injection speed 1.0mm / min, spraying distance 14cm. The aluminum foil on the roller was used to receive the TPU fiber and the BTO nanoparticle synchronously, and the receiving end was connected with a negative pressure of -2kV to prepare a TPU-AgNW conductive composite film.

[0111] (2) Transfer the TPU-AgNW conductive composite film to the polydimethylsiloxane (PDMS) film substrate, and use a laser cutting machine to cut the conductive film into a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com