Preparation method of graphene@ cobalt prussian blue nanocrystalline composite material, method for preparing working electrode by using graphene@ cobalt prussian blue nanocrystalline composite material and application of graphene@ cobalt prussian blue nanocrystalline composite material

A technology of ene-coated cobalt and Prussian blue, which is applied in the preparation of graphene-coated cobalt-based Prussian blue nanocrystalline composite materials, and in the field of electrocatalytic reduction of nitrate nitrogen in sewage, which can solve complex preparation methods and serious secondary pollution , Nitrogen selectivity is poor and other problems, to achieve the effect of high nitrogen selectivity, fast speed, cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]This embodiment provides a method for preparing graphene-coated cobalt-based Prussian blue nanocrystalline composite material Co PBA-rGO, comprising the following steps:

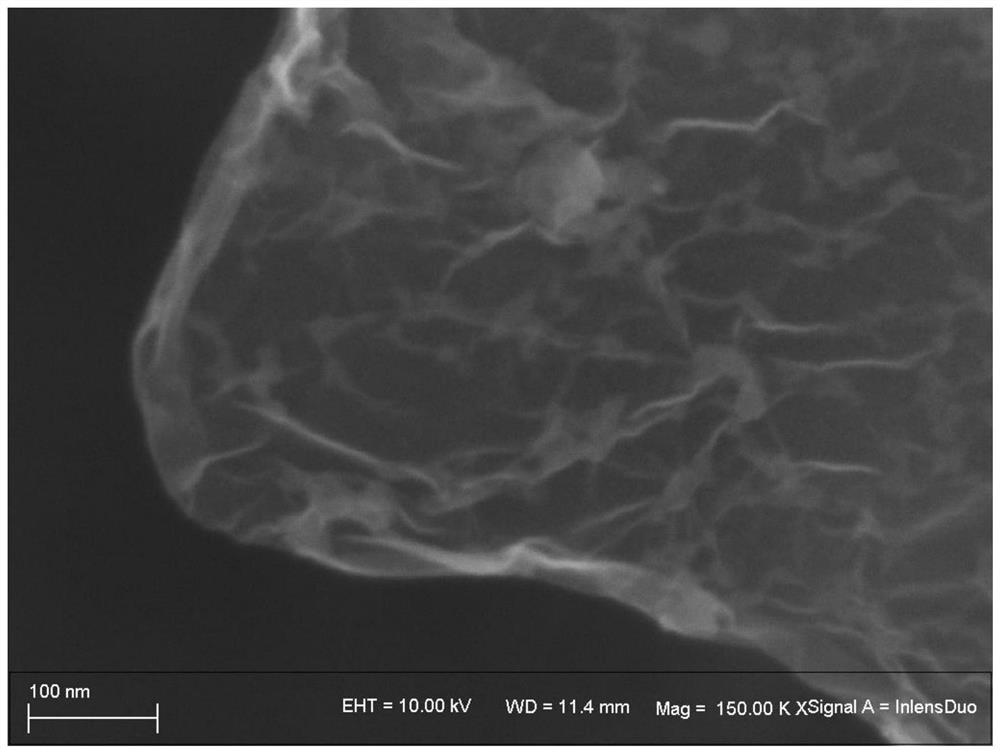

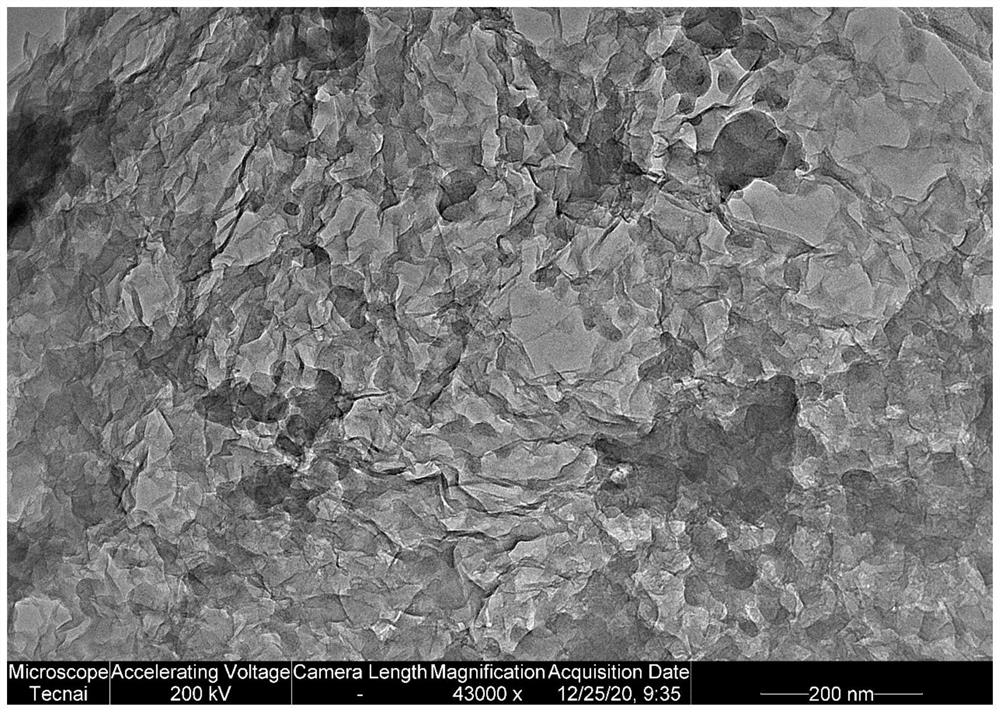

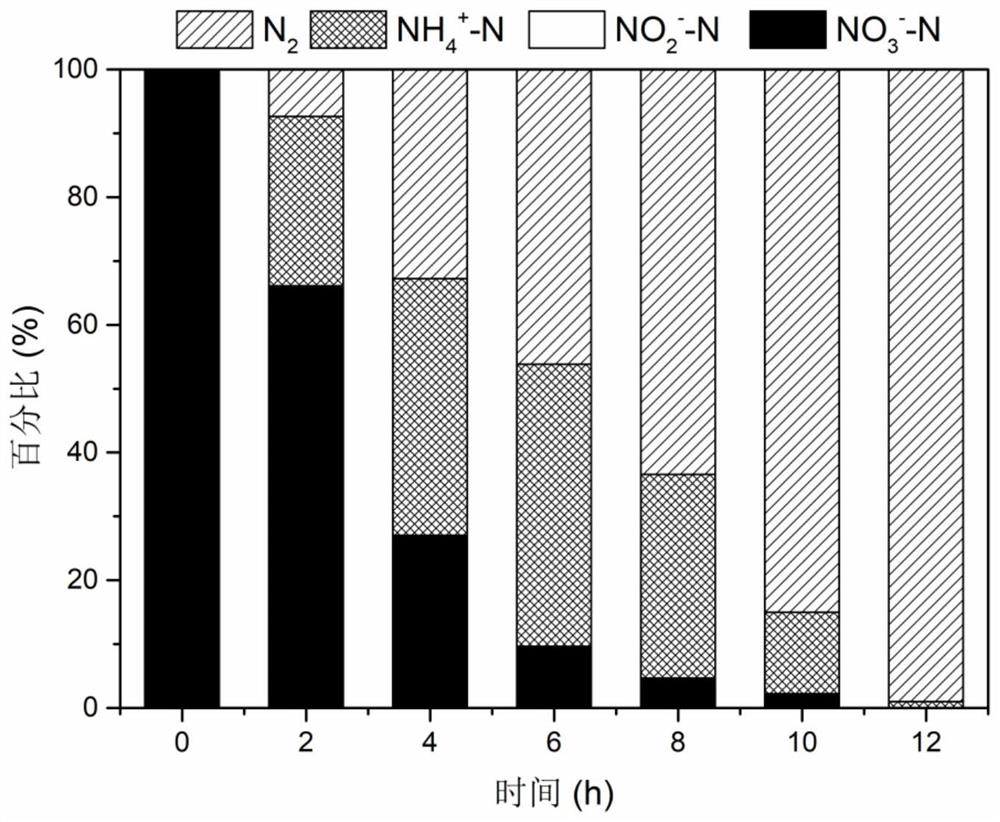

[0036] Add 0.5 mL of 0.2 mol / L potassium cobalt cyanide solution to 100 mL of 1 g / L graphene oxide dispersion, stir for 10 min and sonicate for 5 min respectively. Next, add 5 mL of 0.5 mol / L cobalt chloride solution to the above mixture, stir for 12 hours, centrifuge at 10,000 rpm for 10 minutes, freeze-dry the obtained solid for 24 hours, and then calcinate at 350°C for 2 hours in argon to obtain graphene-coated cobalt Prussian blue-like nanocrystalline composite CoPBA-rGO. The SEM and TEM images of the composite material CoPBA-rGO synthesized in this example are as follows: figure 1 and figure 2 shown. It can be seen that cobalt-like Prussian blue nanocrystals are uniformly coated in graphene. Co PBA-rGO, carbon black and 10g / L polyvinylidene fluoride in N-methylpyrrolidone solution (prepared ...

Embodiment 2

[0038] The preparation method and application of the graphene-coated cobalt-based Prussian blue nanocrystalline composite material provided in this example are basically the same as in Example 1, except that the volume of potassium cobaltcyanide solution is 0.25mL, cobalt chloride The volume of the solution was 2.5 mL. The removal rate of nitrate nitrogen by electrocatalytic reduction was 91.82%, the nitrogen selectivity was 63.43%, and no nitrate nitrogen was detected (<0.02mg / L).

Embodiment 3

[0040] The preparation method and application of the graphene-coated cobalt-based Prussian blue nanocrystalline composite material provided in this example are basically the same as in Example 1, except that the volume of potassium cobalt cyanide solution is 0.75mL, cobalt chloride The volume of the solution was 7.5 mL. The removal rate of nitrate nitrogen by electrocatalytic reduction was 90.60%, the nitrogen selectivity was 96.84%, and no nitrate nitrogen was detected (<0.02mg / L).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com