Lithium cobalt oxide composite material and preparation method thereof

A composite material, lithium cobalt oxide technology, applied in the direction of active material electrodes, electrical components, electrochemical generators, etc., can solve the problems of poor stability and poor conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

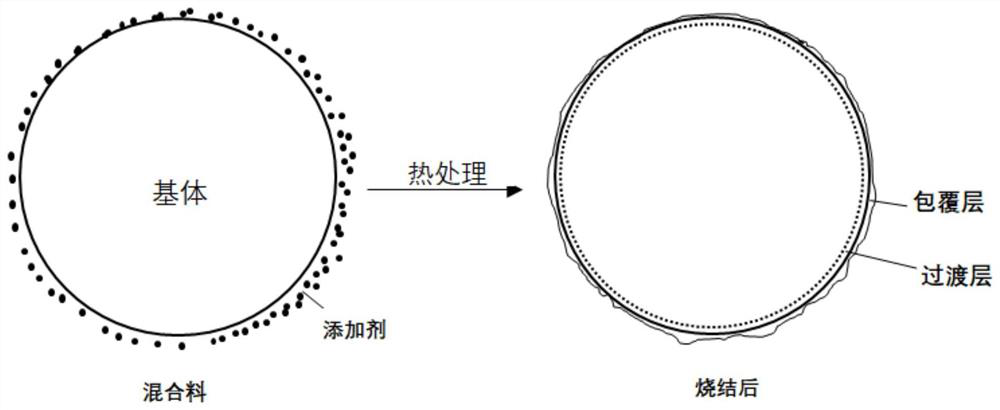

Method used

Image

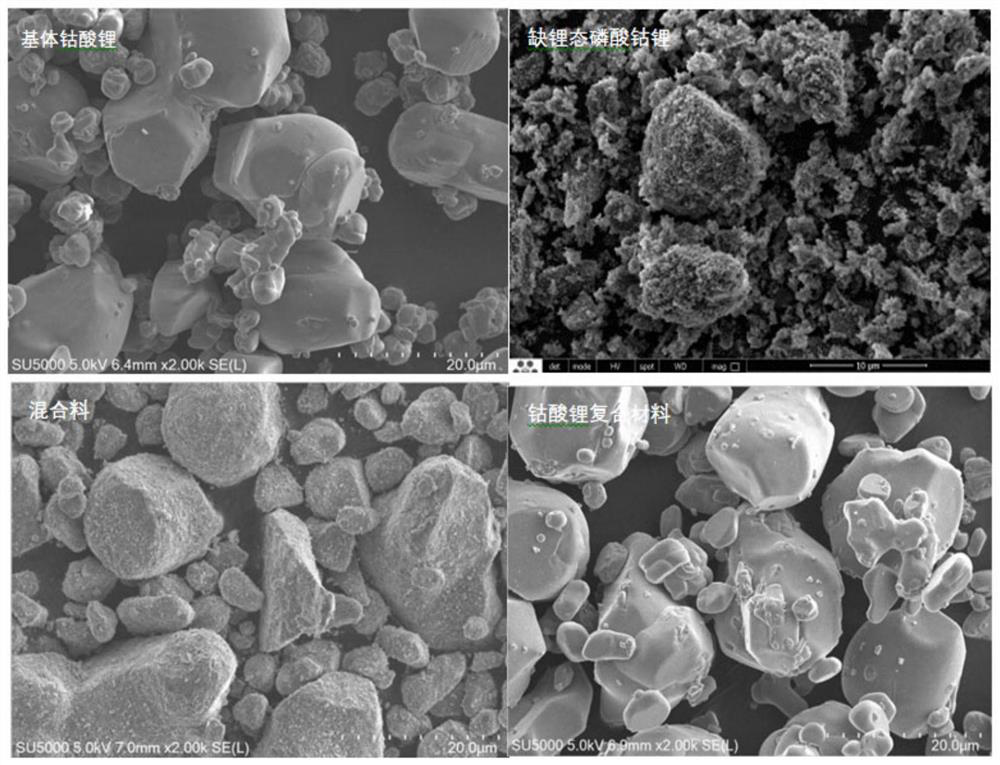

Examples

preparation example Construction

[0054] According to other embodiments of the present invention, the nanoscale lithium-deficient lithium cobalt phosphate Li x CoPO 4 (0.3<x<0.7) preparation method comprises the following steps:

[0055] (1) Lithium nitrate 0.15-1.7mol / L cobalt nitrate salt mixed solution of configuration 0.1-0.5mol / L, the amount of cobalt nitrate substance is 1.5~3 times of lithium nitrate, pH value is adjusted to 4.5-5.5, obtains solution A, standby;

[0056] (2) Configure a mixed solution of 0.1-0.5mol / L phosphoric acid and 0.1-0.5mol / L sodium N-acyl sarcosine, the amount of phosphoric acid is 1.5 to 3 times that of sodium N-acyl sarcosine to obtain solution B ;

[0057] (3) Solution A and solution B are mixed in equal volumes, and subjected to hydrothermal treatment at a temperature of 100-150° C. for 6-8 hours; a solid material is obtained after washing and drying;

[0058] (4) Sintering the obtained solid material, the sintering temperature is 500-700°C, and the sintering time is 3-6...

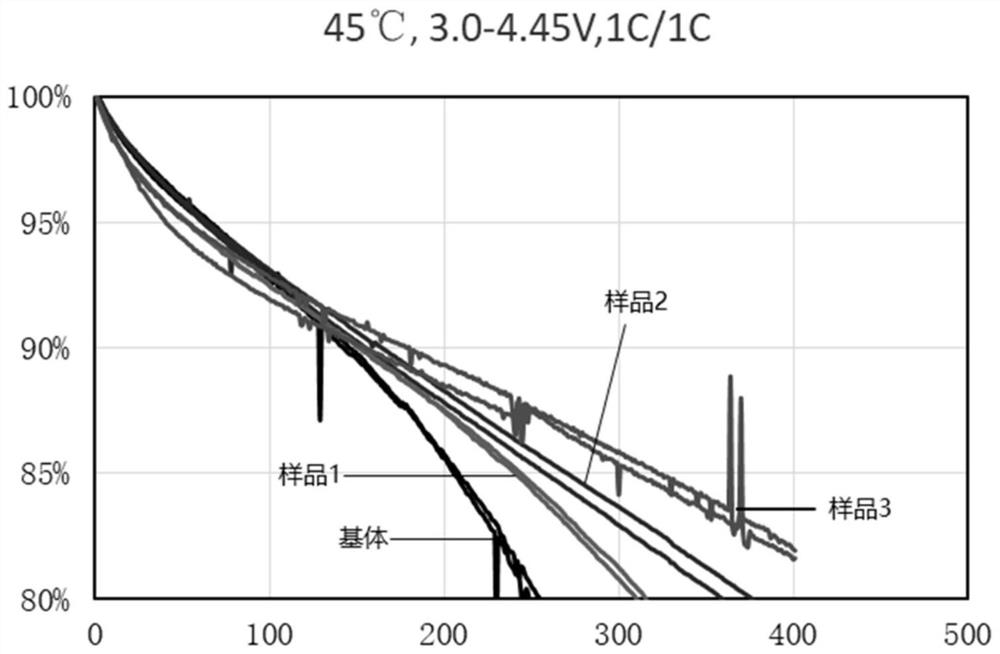

Embodiment 1

[0069] Step 1: Preparation of lithium-deficient lithium cobalt phosphate

[0070] Dissolve 0.1 mol of lithium nitrate and 0.3 mol of cobalt nitrate in 1L of deionized water, adjust the pH to 5.5, then add 0.3 mol of phosphoric acid and 0.1 mol of sodium N-acyl sarcosine to it, and conduct a hydrothermal reaction at 100°C for 6 hours. Cool and dry after the end to obtain a solid precursor; pre-burn the precursor at 180°C for 2 hours in a nitrogen environment, then raise the temperature to 700°C at a rate of 5°C / min, and sinter at a constant temperature for 3 hours to obtain lithium-deficient cobalt phosphate Lithium Li 0.33 CoPO 4 . Lithium-deficient cobalt phosphate lithium Li 0.33 CoPO 4 Pulverized to obtain nano-scale lithium-deficient lithium cobalt phosphate Li 0.33 CoPO 4 .

[0071] The second step: preparation of lithium cobalt oxide composite material

[0072] Take 500g of matrix lithium cobaltate, and take 0.2g of pulverized lithium-deficient lithium cobalt pho...

Embodiment 2

[0086] Step 1: Preparation of lithium-deficient lithium cobalt phosphate

[0087] Dissolve 0.1 mol of lithium nitrate and 0.10 mol of cobalt nitrate in 1L of deionized water, adjust the pH to 5.0, then add 0.15 mol of phosphoric acid and 0.1 mol of sodium N-acyl sarcosine to it, and conduct a hydrothermal reaction at 120°C for 8 hours. Cool and dry after the end to obtain a solid precursor; pre-burn the precursor at 180°C for 2 hours in a nitrogen environment, then raise the temperature to 500°C at a rate of 3°C / min, and sinter at a constant temperature for 3 hours to obtain lithium-deficient cobalt lithium phosphate Li 0.66 CoPO 4 . Lithium-deficient cobalt phosphate lithium Li 0.66 CoPO 4 Pulverized to obtain nano-scale lithium-deficient lithium cobalt phosphate Li 0.66 CoPO 4 .

[0088] The second step: preparation of lithium cobalt oxide composite material

[0089] Take 500g of matrix lithium cobaltate, and take 0.10g of pulverized lithium-deficient cobalt lithium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com