Method for synthesizing ammonia through high-temperature electrolysis by taking low-concentration gas as fuel

A low-concentration gas, high-temperature electrolysis technology, applied in fuel cells, electrolysis components, electrolysis processes, etc., can solve the problems of complex separation and concentration technology, low gas concentration, and difficulty in improving ammonia conversion rate, so as to improve electrolysis efficiency and increase Synthesis rate, the effect of improving comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

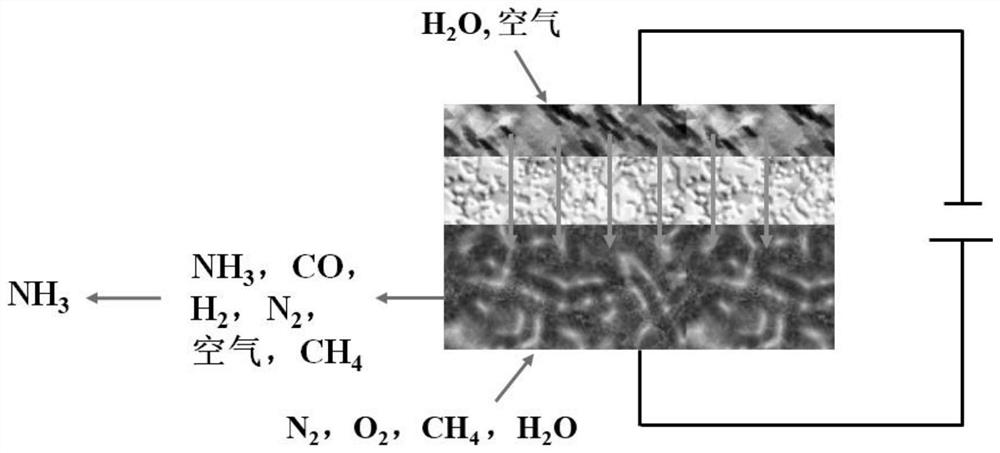

[0024] A method for high-temperature electrolytic ammonia synthesis using low-concentration gas as fuel, comprising the following steps:

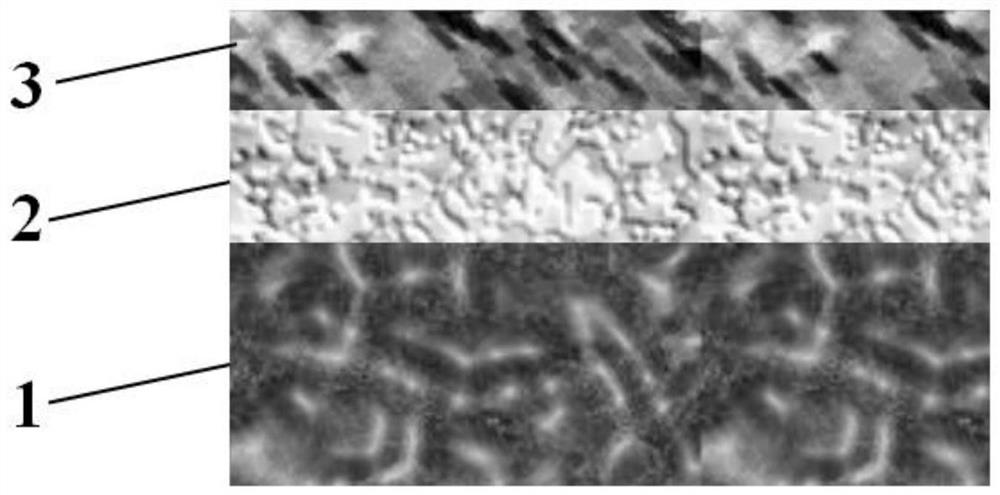

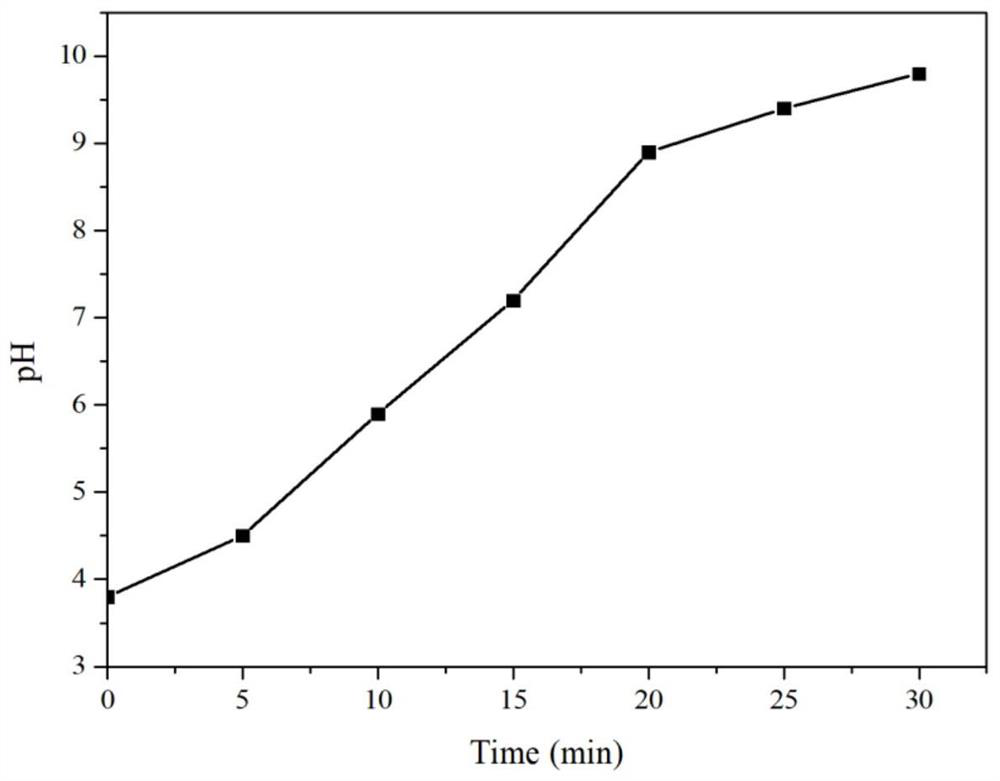

[0025] (1) Preparation of cathode, anode and electrolyte materials, the specific synthesis method is as follows: according to the cathode (NiO, BaZr 0.3 Ce 0.5 Y 0.2 o 3-δ ), anode (BaZr 0.3 Ce 0.5 Y 0.2 o 3-δ , La 0.6 Sr 0.4 co 0.2 Fe 0.8 o 3-δ ), electrolyte (BaZr 0.3 Ce 0.5 Y 0.2 o 3-δ ) The ingredients of each composition take metal nitrate raw material, and add into water successively to obtain the mixed solution that contains each ion, after stirring evenly, add complexing agent in the mixed solution, the addition amount of complexing agent is the molar number of metal ion in the solution The complexing agent is one or two of ethylenediaminetetraacetic acid and citric acid. St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com