A kind of anti-spotting agent for nylon dyeing and its application method

An application method, nylon technology, applied in the field of textile printing and dyeing, can solve the problem of difficult to remove dark spots on the cloth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

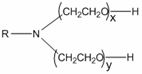

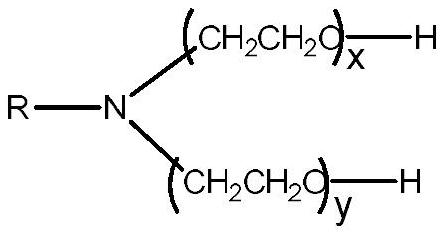

Method used

Image

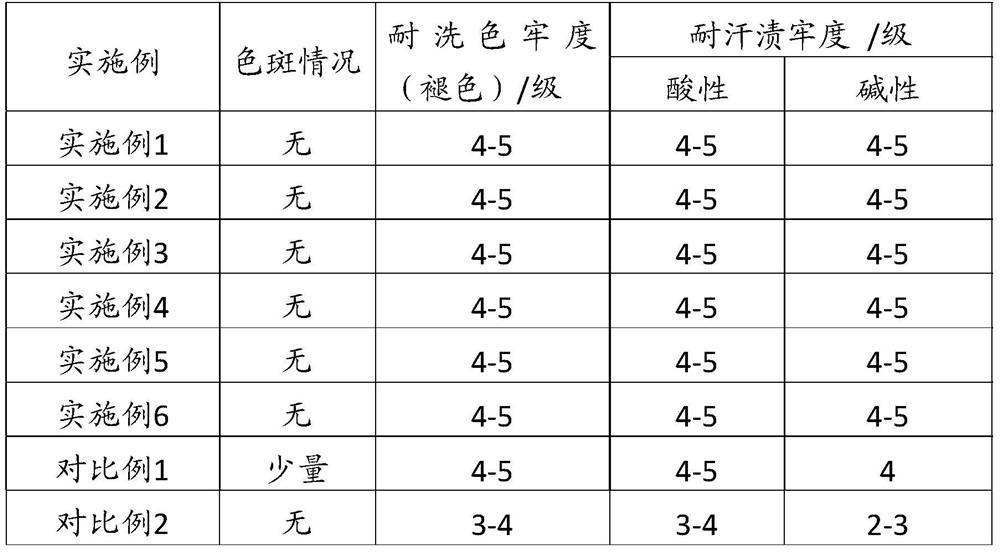

Examples

Embodiment 1

[0032] (1) Fabric type: nylon matte weft-knitted plain weave (40D / 34F, 120g / m 2 )

[0033] (2) The process flow is as follows:

[0034] Preparation of carboxymethylated fatty amine polyoxyethylene ether: Add 0.1 mol of fatty amine polyoxyethylene ether (AC1803), 0.12 mol of chloroacetic acid, and 0.24 mol of sodium hydroxide in the reaction kettle, and react at a temperature of 80°C for 4 After one hour, the temperature was lowered to 40°C; an equal volume of ethanol was added to the reaction mixture, the white precipitate was filtered off, the ethanol was evaporated under reduced pressure at 40°C, and the milky yellow paste obtained was the carboxymethylated fatty amine polyoxygen vinyl ether.

[0035] Compounding of anti-fixation stain agent: by mass percent, carboxymethylated fatty amine polyoxyethylene ether 15%, chelating dispersant (sodium citrate 2%, low molecular weight maleic acid-acrylic acid copolymer 2%) %), 0.05% of organic silicon defoamer, and the balance of ...

Embodiment 2

[0038] (1) Fabric type: nylon matte weft-knitted plain weave (70D / 34F, 150g / m 2 )

[0039] (2) The process flow is as follows:

[0040] Preparation of carboxymethylated fatty amine polyoxyethylene ether: Add 0.1 mol of fatty amine polyoxyethylene ether (AC1803), 0.24 mol of chloroacetic acid, and 0.48 mol of sodium hydroxide in the reaction kettle, and react at 100°C for 2 After one hour, the temperature was lowered to 40°C; an equal volume of ethanol was added to the reaction mixture, the white precipitate was filtered off, the ethanol was evaporated under reduced pressure at 40°C, and the milky yellow paste obtained was the carboxymethylated fatty amine polyoxygen vinyl ether.

[0041]Compounding of anti-spotting agent: by mass percentage, 30% of carboxymethylated fatty amine polyoxyethylene ether, chelating dispersant (4% of sodium tartrate, 4% of low molecular weight sodium polyacrylate), organic silicon 0.1% of defoaming agent and water as the balance, compounded to fo...

Embodiment 3

[0044] (1) Fabric type: Nylon and nylon (70D / 30F×70D / 30F, 190T)

[0045] (2) The process flow is as follows:

[0046] Preparation of carboxymethylated fatty amine polyoxyethylene ether: Add 0.1 mol of fatty amine polyoxyethylene ether (AC1807), 0.16 mol of chloroacetic acid, and 0.32 mol of sodium hydroxide in the reaction kettle, and react at a temperature of 90°C for 3 After one hour, the temperature was lowered to 40°C; an equal volume of ethanol was added to the reaction mixture, the white precipitate was filtered off, the ethanol was evaporated under reduced pressure at 40°C, and the milky yellow paste obtained was the carboxymethylated fatty amine polyoxygen vinyl ether.

[0047] Compounding of anti-spotting agent: by mass percentage, 20% of carboxymethylated fatty amine polyoxyethylene ether, chelating dispersant (3% of iminodiacetic acid, 3% of polyaspartic acid), organic 0.1% of silicon defoaming agent and water as the balance, compounded to form nylon dyeing anti-f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com