Multilayer nano-composite resin, preparation method and application of multilayer nano-composite resin in dye wastewater

A nano-composite and resin technology, applied in the fields of energy and wastewater treatment, chemical instruments and methods, water pollutants, etc., can solve the problems of difficult separation, small size, easy agglomeration, etc., achieve high research value, simple and convenient reaction process, structure novel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

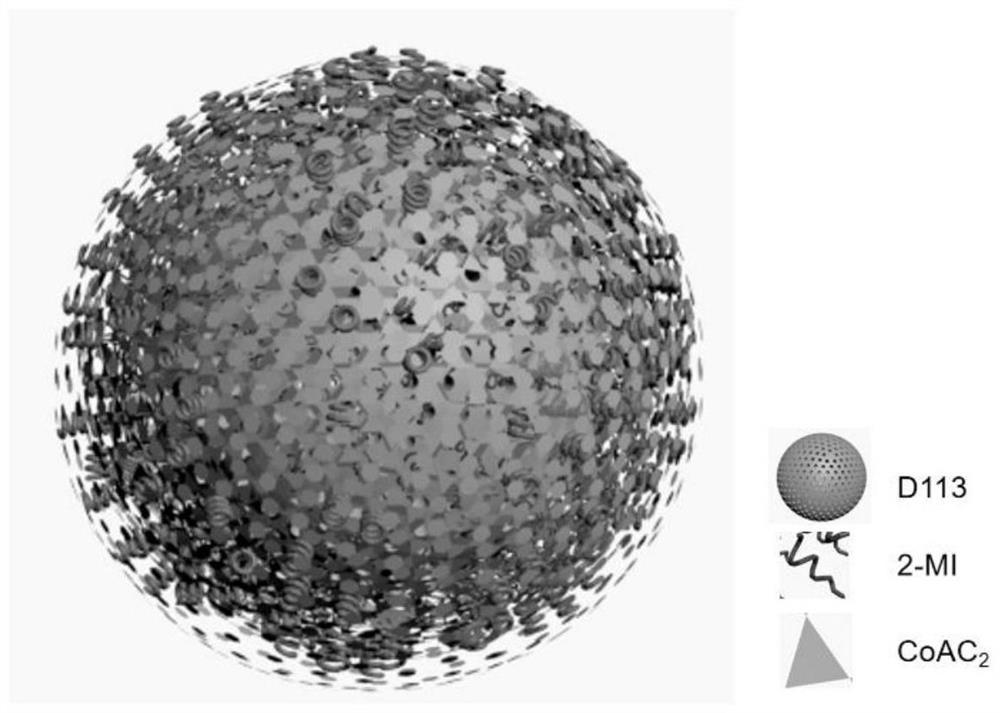

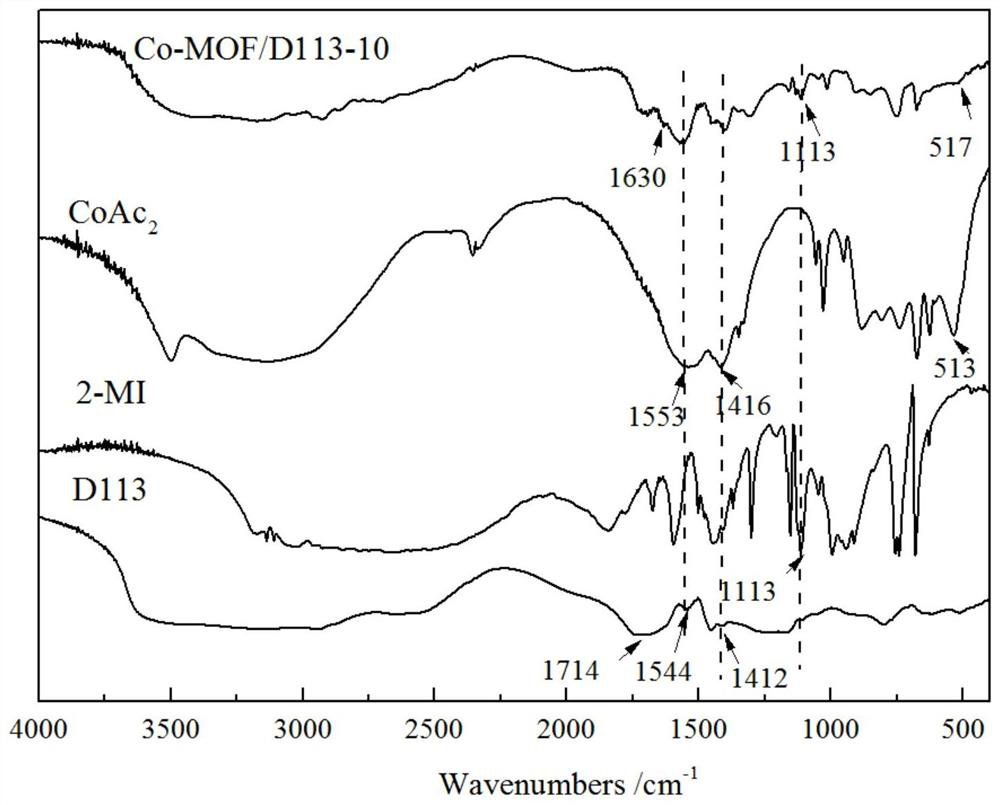

[0028] D113 is a polyacrylic acid type weak acid resin based on allyl itaconate and divinylbenzene as a secondary crosslinking agent. Good-quality D113 resin has a neat spherical appearance, uniform milky white, high strength, generally not easy to break, no abnormal particles, no impurities, basically no cracked balls, and the spherical rate is 100%. D113 shows excellent separation and enrichment performance, and it is low in cost, large in adsorption capacity, good in strength, and can be used repeatedly. In the swollen state, D113 has both the gaps between the polymer chains and the macropores (several to hundreds of nanometers) produced by the porogen during synthesis; although the gaps between the chains disappear after dehydration, the macropores can still be reserved. D113 is suitable for the selective adsorption and separation of various heavy metal ions due to its stable skeleton structure, rich surface functional groups, adjustable pore structure, and large adsorpti...

Embodiment 2

[0034] This example provides a method for preparing multilayer nanocomposite resin Co-MOF-D113-10, the process steps are:

[0035] (1) Raw material pretreatment: soak and swell the ion exchange adsorption resin in distilled water for more than 24 hours, wash with deionized water and suction filter to obtain the pretreatment resin;

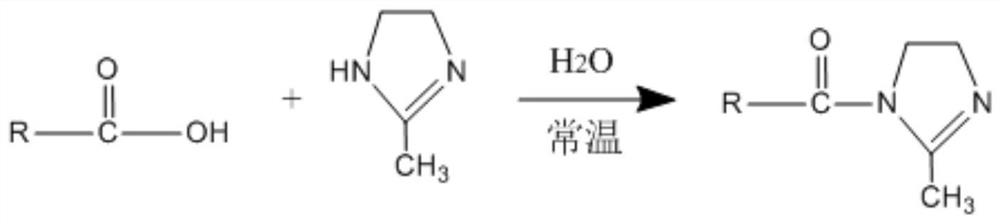

[0036] (2) Preparation of 2-MI / D113: Add the pretreated resin prepared in step (1) to the 2-methylimidazole solution, add a magnet at room temperature and stir for 30min to 2h. Repeated washing with absolute ethanol and deionized water, suction filtration and drying to obtain 2-MI / D113 resin.

[0037] (3) Preparation of Co-MOF / D113-1: add the pretreated resin obtained in step (2) to cobalt acetate solution, and react at room temperature. Water was washed repeatedly, suction filtered and dried to obtain Co-MOF / D113-1 resin.

[0038] (4) Take the product of step (3), and then repeat (2) (3) step 9 times to obtain the product Co-MOF / D113-10. After t...

Embodiment 3

[0052] In this example, the nanocomposite resin of the above example is used in the separation and adsorption experiment of rhodamine B. The results show that the Co-MOF / D113-10 resin has excellent adsorption selectivity for rhodamine B, and the adsorption capacity is large. About 303.7mg / g, refer to the structure after adsorption of Rhodamine B Figure 4 hint.

[0053] The material can be applied to the adsorption of organic cation RB in the environment or food. In various printing and dyeing wastewater containing organic cation RB, rhodamine B can be recognized and adsorbed by the nanocomposite resin described in claim 1 to form complex ions or complexes. The specific adsorption process is:

[0054] Take 50mg of Co-MOF / D113-10 and add it to a 250mL iodine flask, add 25mL of 0.2mol / LHAc-NaAc buffer solution with a pH of 2 to 7 to swell for 12h, then add 5mL of 2000ppm rhodamine B standard stock solution, at 15 Under the temperature of ℃~35℃, use a constant temperature oscil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap