Hyperaccumulator plant biomass recycling method

A technology for hyper-accumulation of plant and biomass resources, applied in ion exchange regeneration, chemical/physical processes, pulping with organic compounds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

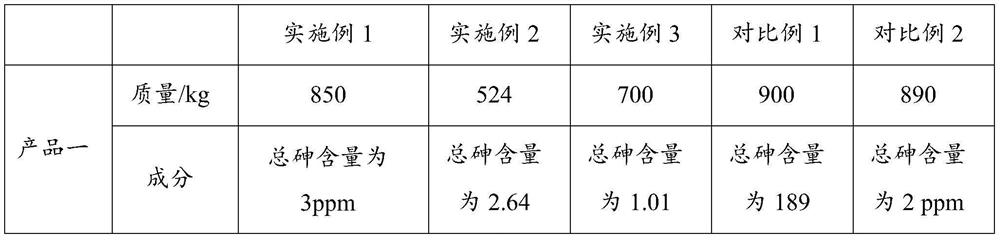

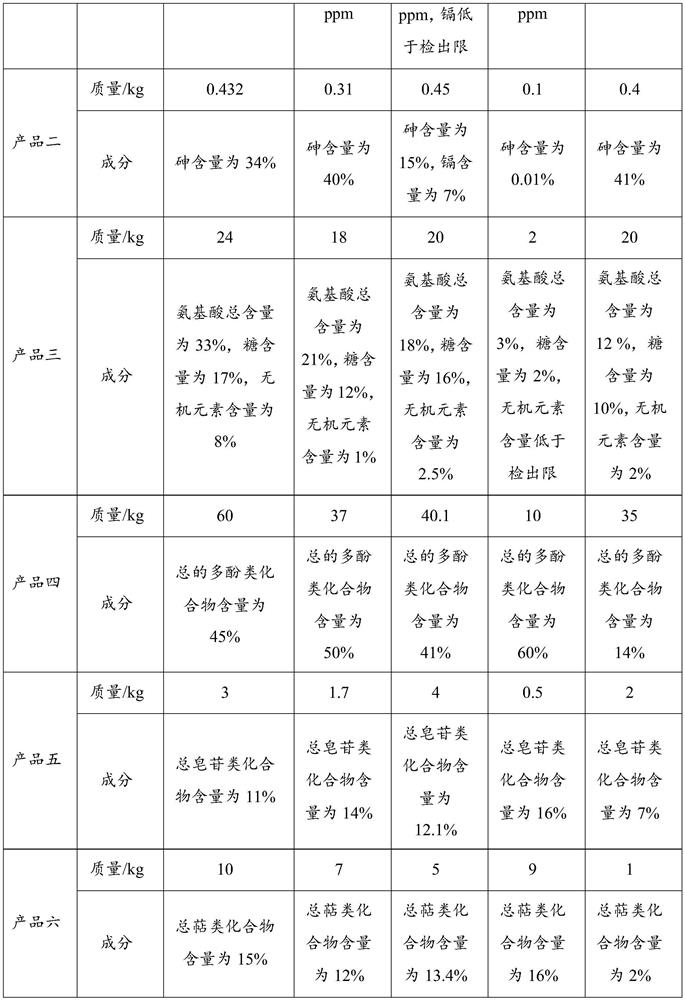

Examples

Embodiment 1

[0051] This embodiment provides a method for resource utilization of hyperaccumulated plant biomass, which specifically includes the following steps:

[0052] Collect 2.5 tons of the above ground part of fresh centipede grass from moderately arsenic-polluted farmland, its water content is 60%, after directly crushing and homogenizing, use 6000L of ethanol aqueous solution with a volume fraction of 47%, at 60 ℃, 25KHz ultrasonic extraction for 180min, extract Incubate for 2 hours after the end, collect the first extraction solution and the first extraction residue;

[0053] The first extraction residue was further heated and extracted with 8000 L of ethanol aqueous solution with a volume fraction of 95% at 80° C. for 180 minutes, and kept for 2 hours after the extraction was completed, and the second extraction liquid and the second extraction residue were collected;

[0054] The second extraction residue was further dissolved in 5000 L of ethanol with a volume fraction of 65%,...

Embodiment 2

[0062] This embodiment provides a method for resource utilization of hyperaccumulated plant biomass, which specifically includes the following steps:

[0063] Collect fresh 3.1 tons of aboveground parts of centipede grass from heavily arsenic-polluted farmland, with a moisture content of 80%, stored at a humidity of 60%, at a temperature of 10 degrees Celsius, and protected from direct sunlight for 2 days, then freeze-dried for 3 days , measure its moisture content to be 10%, after cutting to 0.1mm, use 4340L ethanol aqueous solution with a volume fraction of 75%, ultrasonically extract at 40°C and 60KHz for 20min, keep warm for 1 hour after extraction, collect the first extract and the second - extraction residue;

[0064] The first extraction residue was further heated and extracted with 3500 L of ethanol aqueous solution with a volume fraction of 35% at 40° C. for 140 minutes, and kept for 1 hour after the extraction was completed, and the second extraction liquid and the s...

Embodiment 3

[0073] This embodiment provides a method for resource utilization of hyperaccumulated plant biomass, which specifically includes the following steps:

[0074] From moderate cadmium polluted farmland, 1 ton of fresh Sedum sedum above ground is collected, and its water content is 60%; 1.6 tons of above ground parts of fresh centipede grass are collected, and its water content is 75%; After collecting and directly pulverizing the homogenate, use 8000L of methanol aqueous solution with a volume fraction of 64%, heat and extract at 80°C for 120min, keep warm for 2 hours after the extraction, and collect the first extraction solution and the first extraction residue;

[0075] The first extraction residue was further extracted with 5600L of methanol aqueous solution with a volume fraction of 55%, ultrasonically extracted at 60°C and 40KHz for 20 minutes, and kept for 2 hours after the extraction was completed, and the second extraction solution and the second extraction residue were col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com