Low-temperature-resistant online variable-viscosity agent and preparation method thereof

A low-temperature and viscosity-resistant technology, which is applied in the preparation of low-temperature online viscosity-changing agent composition, low-temperature online viscosity-changing agent and its preparation field, can solve the problems of not being able to be used as a drag reducer, and is not easy to stick and break milk, extend the shelf life, and stabilize the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] In the second aspect, the present invention provides a method for preparing an anti-low temperature online viscosifying agent, the anti-low temperature online viscosifying agent adopts the composition for preparing an anti-low temperature online viscosifying agent described in the first aspect of the present invention Prepared, the composition used to prepare the anti-low temperature online viscosity change agent described in the present invention is the raw material for preparing the low temperature online viscosity change agent, and the preparation method includes the following steps:

[0037] (a) Mix acrylamide, 2-acrylamido-2-methylpropanesulfonic acid, methacryloyloxyethyl-N,N-dimethylpropanesulfonate, structure modifier and water to obtain The first mixed solution, then adding sodium hydroxide to the first mixed solution to adjust the pH value of the first mixed solution is 6.5~7.5 (such as 6.5, 6.6, 6.7, 6.8, 6.9, 7.0, 7.1, 7.2 , 7.3, 7.4 or 7.5) is preferably 7....

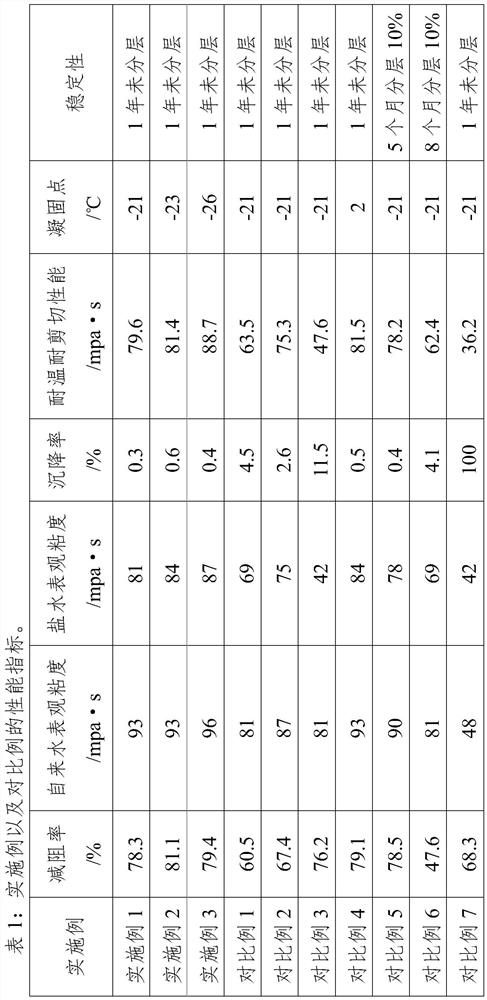

Embodiment 1

[0061] The composition used to prepare the anti-low temperature online viscosity change agent in this embodiment is composed of a dispersed water phase, a continuous oil phase and a process treatment agent;

[0062] The dispersed aqueous phase is composed of the following components in parts by weight:

[0063] 100 parts of acrylamide, 150 parts of 2-acrylamide-2-methylpropanesulfonic acid, 40 parts of methacryloyloxyethyl-N,N-dimethylpropanesulfonate, N-octadecylpropene 5 parts of amide (long-chain flexible monomer), 29 parts of sodium hydroxide, 0.05 parts of N,N-methylenebisacrylamide (structure regulator), 50 parts of sodium chloride (point depressant), 300 parts of water;

[0064] The continuous oil phase is composed of the following components in parts by weight:

[0065] Qilu Petrochemical Shengli Oil Refinery D110 white oil (oily solvent) 200 parts, Span 80 emulsifier 13.1 parts, isomerized tridecyl alcohol polyoxyethylene ether 1307 emulsifier 6.9 parts, hydrophobic ...

Embodiment 2

[0076] The composition used to prepare the anti-low temperature online viscosity change agent in this embodiment is composed of a dispersed water phase, a continuous oil phase and a process treatment agent;

[0077] The dispersed aqueous phase is composed of the following components in parts by weight:

[0078] 125 parts of acrylamide, 175 parts of 2-acrylamide-2-methylpropanesulfonic acid, 50 parts of methacryloyloxyethyl-N,N-dimethylpropanesulfonate, methacrylamide 18 8 parts of alcohol polyoxyethylene ether (long-chain flexible monomer), 33.5 parts of sodium hydroxide, 0.1 part of pentaerythritol triallyl ether (structure modifier), 65 parts of sodium acetate (point depressant), 260 parts of water;

[0079] The continuous oil phase is composed of the following components in parts by weight:

[0080] Qilu Petrochemical Shengli Oil Refinery D110 white oil (oily solvent) 230 parts, cetearyl polyoxyethylene ether-10 emulsifier 12.6 parts, propylene glycol block polyether L61 e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com