Single-component self-crosslinking polyurethane-polyurea aqueous dispersion as well as preparation method and application thereof

A technology of polyurethane and self-crosslinking, which is applied in the fields of dyeing, textiles and papermaking, etc. It can solve the problems of rigidity of polyurethane chain segments, decrease of adhesion, and decrease of flexibility, and achieve the goal of reducing water absorption, improving adhesion, and good emulsification and dispersion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0082] Another aspect of the present invention provides the preparation method of the aforementioned one-component self-crosslinking polyurethane-polyurea aqueous dispersion, comprising the following steps:

[0083] 1) Put the dehydrated components b), components a), f), c) and solvents into the reaction kettle under the protection of inert gas, and raise the temperature to 60-90 ° C for 3-8 hours to obtain the pre-isocyanate terminal Polymer;

[0084] 2) Dilute the obtained isocyanate-terminated prepolymer with a solvent, lower the temperature to below 40°C, and then add component e) for neutralization;

[0085] 3) adding deionized water to disperse under rapid stirring, and then adding component d) containing amino groups to carry out chain extension reaction;

[0086] 4) Removing the solvent to obtain the one-component self-crosslinking polyurethane-polyurea aqueous dispersion.

[0087] If component d) does not contain amino then can be added together with component b), a...

Embodiment 1

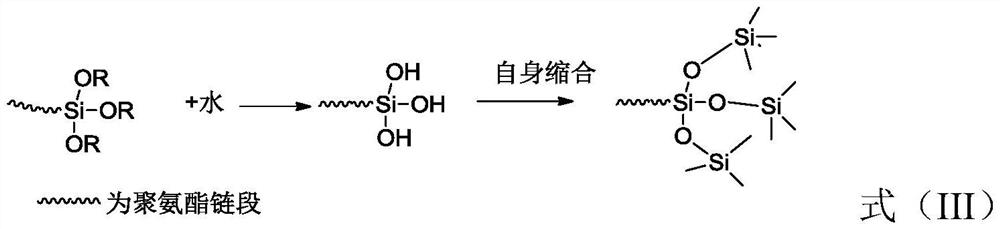

[0110] Add 250g of dehydrated polycaprolactone diol, 50g of liquefied MDI, 10g of HDI, 6g of dimethylolpropionic acid, and 50g of acetone into a 1L four-necked round-bottomed flask equipped with a nitrogen inlet and outlet. Stir the mixture until the NCO reaches 1.36%, lower the temperature below 40°C, add 220g of acetone to dilute, add 2.26g of triethylamine and 5.27g of N,N-dimethylaminopropyltrimethoxysilane for neutralization for about 5min, and stir rapidly Add 398g of deionized water to disperse, then add 2.5g of ethylenediamine for chain extension, and then separate the acetone by distillation to obtain a solvent-free polyurethane-polyurea dispersion. It has a solids content of 45% by weight and an average particle size in the dispersed phase of 203 nm determined by laser correlation, with a pH of 7.5.

Embodiment 2

[0112] Add 250g of dehydrated polytetrahydrofuran diol, 100g of dehydrated polyoxypropylene diol C2020D, 100g of liquefied MDI, 12g of dimethylolpropionic acid and 50g of acetone into a 1L four-port round bottom with nitrogen inlet and outlet In the flask, stir the mixture at 60-90°C until the NCO reaches 1.45%, cool down to below 40°C, add 190g of acetone to dilute, add 4.5g of triethylamine and 10.54g of N,N-dimethylaminopropyltrimethoxysilane Neutralize for about 5 minutes, add 541g of deionized water to disperse under rapid stirring, then add 3.05g of ethylenediamine for chain extension, and separate acetone by distillation to obtain a solvent-free polyurethane-polyurea dispersion. It has a solids content of 45% by weight and an average particle size in the dispersed phase of 193 nm determined by laser correlation, with a pH of 7.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com