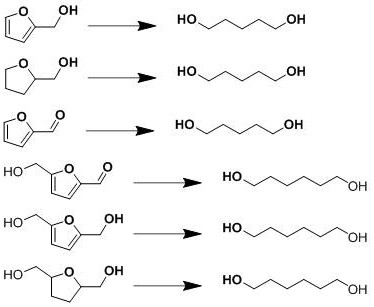

Method for preparing 1,5-pentanediol or 1,6-hexanediol using bio-based furan compounds

A technology based on furan and pentanediol, applied in the field of chemical synthesis, can solve the problems of time-consuming, harsh reaction conditions, difficult industrialization, etc., and achieve the effect of expanding the scope of application and efficient transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Preparation of composite catalyst 10% Ni / 10% Ce / silica: 2g of silica was added to the mixed solution containing 0.1mol / L nickel nitrate and 0.1mol / L cerium nitrate, stirred well for 2h, 20ml of 0.1mol / L ammonium oxalate was slowly added dropwise to the above mixed solution, and continued to stir for 2h; The mixed solution was loaded into a hydrothermal kettle, hydrothermal at 180 °C for 24 h, filtered, washed, dried and calcined in air for 3 h at 400 °C, and then reduced in hydrogen at 300 °C for 3 h to obtain a composite catalyst Ni / 10%Ce / silica;

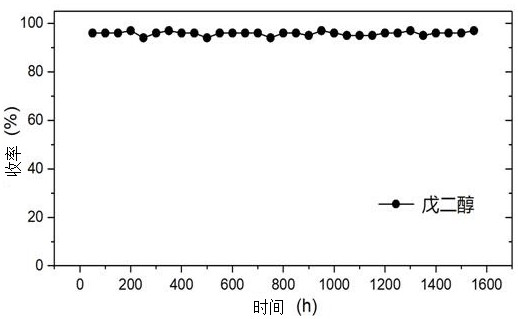

[0023] Preparation of 1,5-Pentanediol: Take the composite catalyst Ni / 10% Ce / prepared above 0.2g of silica and 30ml of water are placed in the high-pressure reactor, and then 10g of furfuryl alcohol is added, hydrogen is replaced three times, and the final hydrogen pressure is 4MPa; heated to 120 °C, the reaction is fully stirred for 24 hours, the reactor is cooled with water to room temperature, the gas is slowly discharged, t...

Embodiment 2

[0027] Preparation of the composite catalyst 30% Ni / yttrium oxide: 0.1mol / L nickel nitrate solution and 0.1mol / L cerium nitrate solution mixed, fully stirred for 1h, 20ml of 0.1mol / L potassium hydroxide slowly added to the above mixed solution, continue to stir for 2h, the mixed solution into a water heat kettle, 140 ° C hydrothermal 24h, filtered, washed, calcined in the air for 6h, and then reduced in hydrogen at 350 ° C for 3h, that is, the composite catalyst 30% Ni / cerium oxide was obtained;

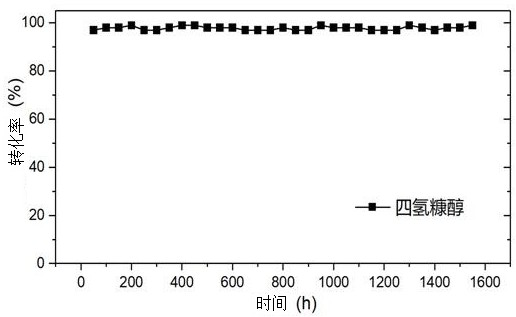

[0028] Preparation of 1,5-Pentanediol: Take 30% Ni / of the above composite catalyst 0.2g cerium oxide and 30ml of ethanol are placed in the high-pressure reactor, and then 5g of tetrahydrofuryl alcohol is added, the hydrogen is replaced three times, the final hydrogen pressure is 5MPa, heated to 200 °C, the reaction is fully stirred for 12 hours, the reactor is cooled with water to room temperature, the gas is slowly discharged, the high-pressure reactor is unloaded and filtere...

Embodiment 3

[0032] Preparation of composite catalyst 0.01% Ru / 50% lanthanum / activated carbon: 2g of activated carbon powder was added to the mixed solution of 0.5mol / L lanthanum nitrate and 0.001mol / L ruthenium chloride, stirred well for 6h, dried, calcined in nitrogen at 550 °C for 3h, and then reduced to 3h at 350 °C in hydrogen, that is, the composite catalyst Ru / 50% lanthanum / activated carbon was obtained;

[0033] Preparation of 1,5-Pentanediol: Ru / 50% lanthanum / , a composite catalyst prepared above Activated carbon 0.2g and tetrahydrofuran 30ml placed in the high-pressure reactor, and then added 2.0g furfury alcohol, hydrogen replacement three times, the final hydrogen pressure is 4MPa, heated to 150 °C, fully stirred under the reaction for 8 hours, cool the reactor with water to room temperature, slowly discharge the gas, unload the high-pressure reactor and filter, the filtrate is chromatographic analysis (the filtrate is equipped with HP-5 capillary column using Shimadzu 2014C gas ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com