Wear-resistant plastic bag and preparation method thereof

A technology of plastic bags and wear-resistant agent, applied in the field of plastic bag preparation, can solve the problems affecting quality and market sales, poor wear resistance and antibacterial performance, etc., and achieve the effect of reducing aggregation and good dispersion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

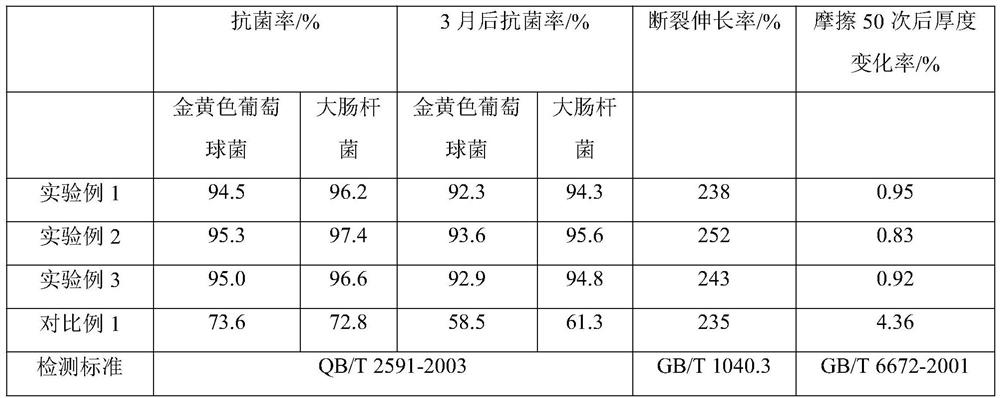

Examples

Embodiment 1

[0047] A wear-resistant plastic bag is composed of the following raw materials in parts by weight: 100 parts of polybutylene succinate and 3 parts of wear-resistant masterbatch; wherein, the wear-resistant masterbatch is calculated by weight percentage and includes the following components: polybutylene succinate Tetrafluoroethylene 0.5%, composite anti-wear agent 12%, nano-titanium dioxide 0.2%, stearic acid 0.25%, polyphenylene ether ketone 0.5%, polydimethylsiloxane 0.3%, octadecyldiethanolamine 0.38%, 4.2% of talcum powder, 0.6% of 2,6-di-tert-butyl-4-methylphenol, 0.36% of coupling agent, 0.52% of plasticizer, and the balance is polybutylene succinate chips.

[0048] The preparation method of composite anti-wear agent comprises the following steps:

[0049] One, the preparation of porous calcium carbonate;

[0050] Weigh an appropriate amount of Na with a particle size of 50 μm 2 CO 3 solid, and transfer it to a suction filtration device, and then slowly add an appropr...

Embodiment 2

[0068] The preparation process of the wear-resistant plastic bag is similar to that of Example 1, except that the ratio of the raw materials used is different; specifically: 110 parts of polybutylene succinate and 10 parts of wear-resistant masterbatch;

[0069] Among them, the wear-resistant masterbatch includes the following components by weight percentage: 0.6% polytetrafluoroethylene, 16% composite wear-resistant agent, 0.3% nano-titanium dioxide, 0.28% stearic acid, 0.55% polyphenylene ether ketone, 0.32% methyl siloxane, 0.45% octadecyldiethanolamine, 4.5% talc, 0.68% 2,6-di-tert-butyl-4-methylphenol, 0.42% coupling agent, 0.56% plasticizer , and the balance is polybutylene succinate chips.

Embodiment 3

[0071] The preparation process of the wear-resistant plastic bag is similar to that of Example 1, except that the ratio of the raw materials used is different; specifically: 120 parts of polybutylene succinate and 18 parts of wear-resistant masterbatch;

[0072] Among them, the wear-resistant masterbatch includes the following components by weight percentage: 0.8% polytetrafluoroethylene, 20% composite wear-resistant agent, 0.4% nano-titanium dioxide, 0.32% stearic acid, 0.6% polyphenylene ether ketone, 0.36% methyl siloxane, 0.52% octadecyldiethanolamine, 5.0% talc, 0.75% 2,6-di-tert-butyl-4-methylphenol, 0.55% coupling agent, 0.6% plasticizer , and the balance is polybutylene succinate chips;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com