Double-component thermosetting epoxy glue with low water absorption rate as well as preparation method and application thereof

A low water absorption, two-component technology, applied in the field of coating adhesives, can solve the problems of low optical properties and incompatible water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

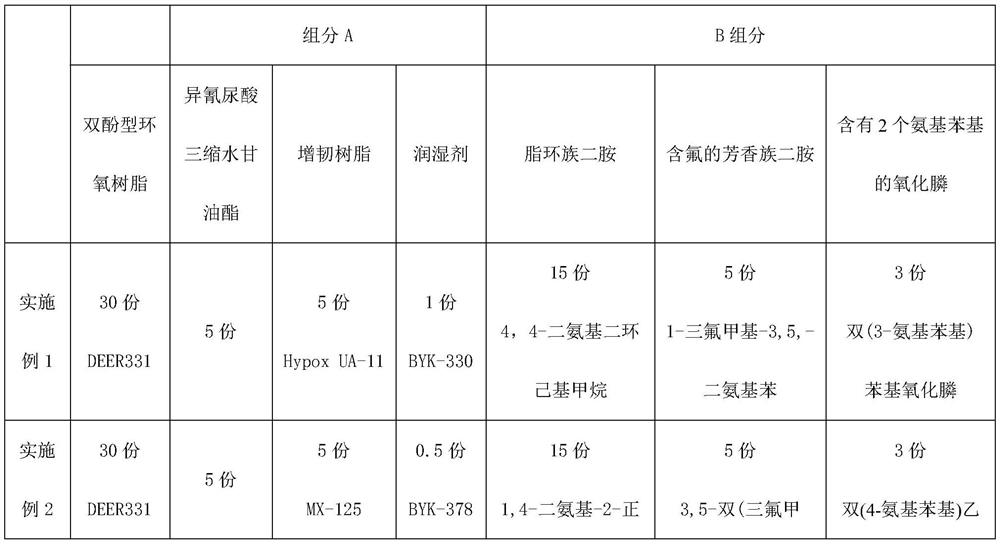

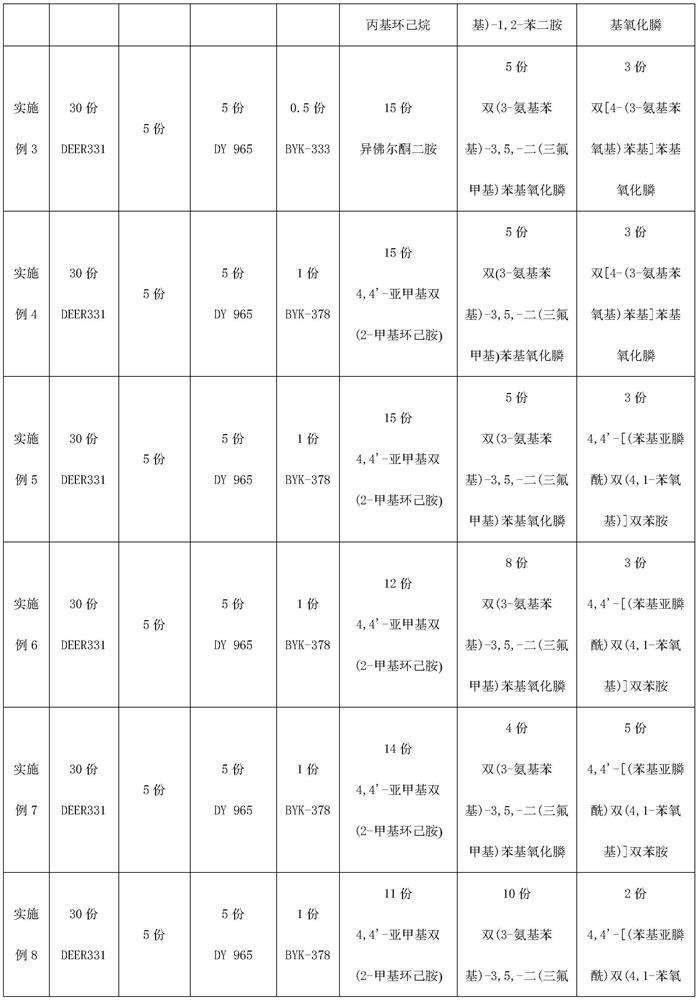

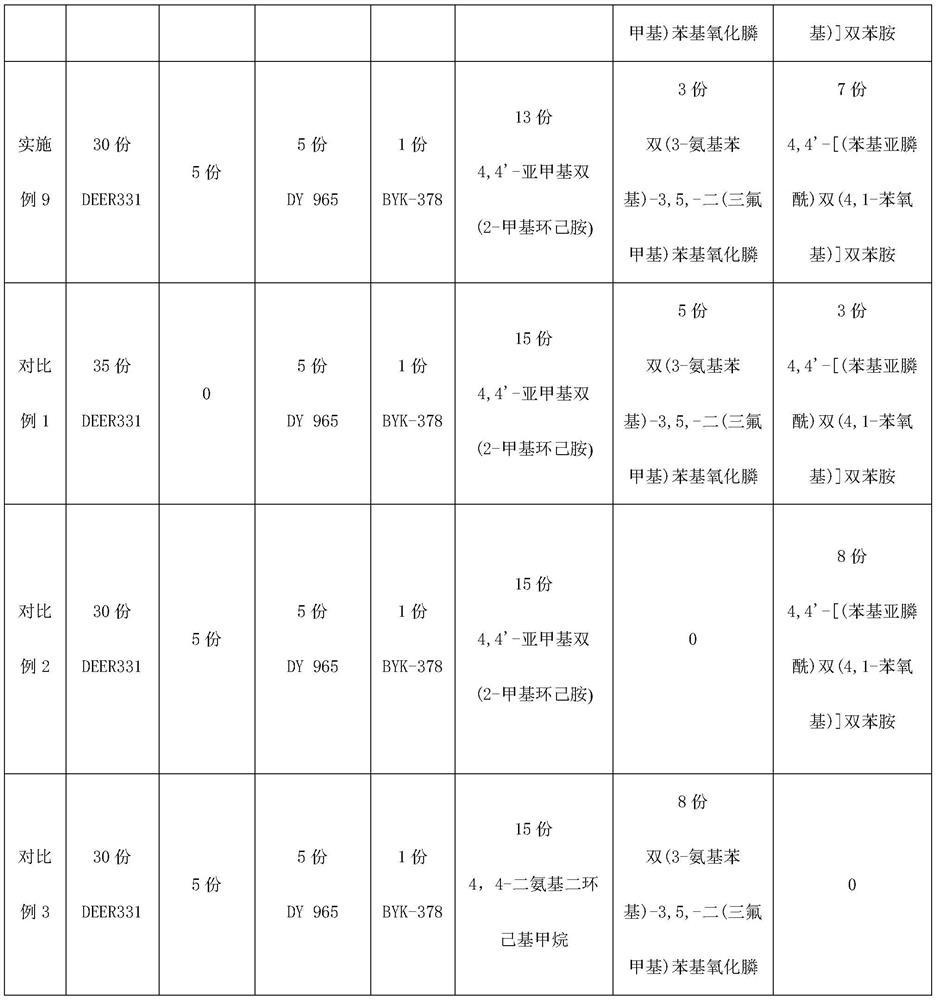

Examples

Embodiment 1

[0030] (1) Preparation of component A: Stir and mix 30 parts of bisphenol A epoxy resin DEER331, 5 parts of triglycidyl isocyanurate, and 15 parts of MHR-070 resin at 80°C, and then add 40 parts of reactive diluent ED-509S, 5 parts of toughening resin HypoxUA-11, 1 part of wetting agent BYK-330, 0.3 parts of defoamer Hemings 5300, 0.5 parts of anti-yellowing additive SKELA-0025, after cooling, add 5 parts of liquid Phosphate ester flame retardant DEEP, mixed evenly to obtain component A;

[0031] (2) Preparation of component B: 15 parts of 4,4-diaminodicyclohexylmethane, 5 parts of 1-trifluoromethyl-3,5,-diaminobenzene, 3 parts of bis(3-aminophenyl ) phenylphosphine oxide, 3 parts of accelerator AC399, and 20 parts of reactive diluent ED-509S are mixed evenly to obtain component B.

[0032] When applying, mix evenly according to the mass ratio of component A and component B 3:1, spray on the PCB board, and can be cured at medium temperature (80°C / 1h+100°C / 0.5h), control the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com