Low-surface treatment heavy anti-corrosion coating as well as preparation method and application thereof

A low-surface treatment, heavy-duty anti-corrosion technology, applied in the field of coatings, can solve the problems that the anti-corrosion effect cannot reach the expected effect, it is difficult to reach the base surface treatment level, and the solvent content is high, and achieve excellent permeability and adhesion, adhesion and Good salt spray resistance and low surface treatment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

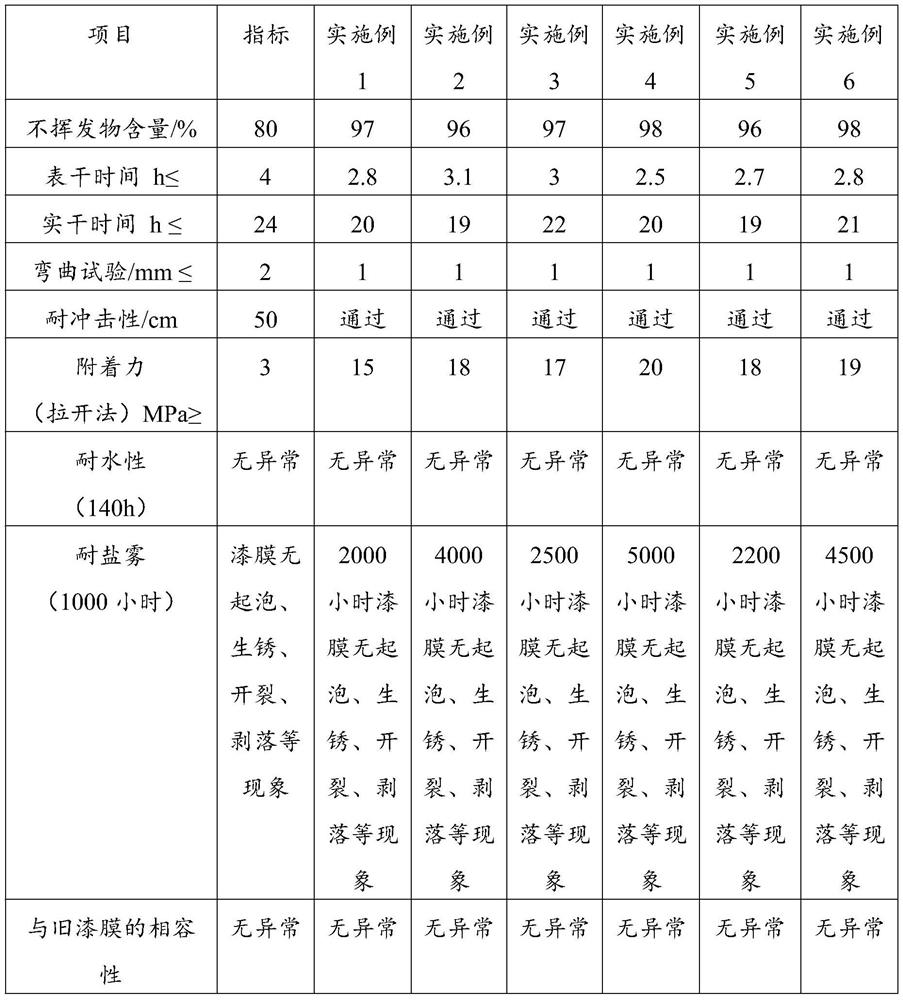

Examples

preparation example Construction

[0057] The present invention also provides a preparation method of low surface treatment heavy-duty anti-corrosion coating, comprising the steps of:

[0058] (1) Mix the first film-forming resin, the second film-forming resin, epoxy diluent, hydrocarbon resin, coupling agent and auxiliary agent, stir at 100-500rpm for 5-15min, then add titanium dioxide, mineral Powder, anti-rust pigment, inorganic powder, pigment, adjust the rotation speed at 1000-1500rpm, stir for 30-40min, grind until the particle size is 10-40μm, and filter to obtain component A;

[0059] (2) Mix the first curing agent, the second curing agent, modifier, accelerator and adhesion promoter, and stir for 30 to 40 minutes at a rotation speed of 100 to 800 rpm to obtain component B;

[0060] (3) Mix component A and component B to obtain a low surface treatment heavy-duty anti-corrosion coating.

[0061] The present invention also provides an application of a low-surface-treatment heavy-duty anti-corrosion paint...

Embodiment 1

[0064] The invention provides a low-surface treatment heavy-duty anti-corrosion coating, which is prepared from raw materials containing the following parts by mass:

[0065] Component A: 18 parts of tung oil-based epoxy resin, 12 parts of tung oil modified phenolic epoxy resin, 10 parts of gallic acid-based epoxy resin, 1 part of cashew nut shell oil diluent, 10 parts of xylene formaldehyde resin, rutile titanium dioxide 20 parts, 5 parts of mica powder, 25 parts of zinc phosphate, 1 part of silicon dioxide powder, 5 parts of 3-glycidyl etheroxypropyl trimethoxysilane, 1 part of inorganic pigment, 3 parts of corrosion inhibitor, defoamer 2 copies;

[0066] Component B: 5 parts of fatty amine, 25 parts of cashew shell oil modified polyamide, 2 parts of ketimine, 3 parts of benzyl alcohol, 0.5 part of aminosilane;

[0067] Wherein, the weight ratio of A component and B component is 5:1.

[0068] The present invention also provides a preparation method of low surface treatment...

Embodiment 2

[0073] The invention provides a low-surface treatment heavy-duty anti-corrosion coating, which is prepared from raw materials containing the following parts by mass:

[0074] Component A: 10 parts of tung oil-based epoxy resin, 10 parts of tung oil modified phenolic epoxy resin, 20 parts of itaconic acid-based epoxy resin, 15 parts of cashew nut shell oil diluent, 1 part of C9 petroleum resin, phenol modified petroleum 1 part of resin, 1 part of rutile titanium dioxide, 15 parts of glass flakes, 20 parts of zinc phosphate, 5 parts of zinc molybdate, 10 parts of silicon dioxide powder, 1 part of 3-glycidyl etheroxypropyl trimethoxysilane, 5 parts of inorganic pigment, 1 part of corrosion inhibitor;

[0075] Component B: 5 parts of fatty amine, 25 parts of cashew nut shell oil modified phenalkamine, 1 part of ketimine, 2 parts of benzyl alcohol, 1 part of salicylic acid, 5 parts of aminosilane;

[0076] Wherein, the weight ratio of A component and B component is 6:1.

[0077] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com