Heat-insulating corrosion-resistant powder coating material and preparation method thereof

A powder coating and corrosion-resistant technology, used in powder coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve problems such as inappropriateness, emission, and easy powdering of the coating film, and achieve increased porosity, widened lamellar spacing, and improved dispersive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

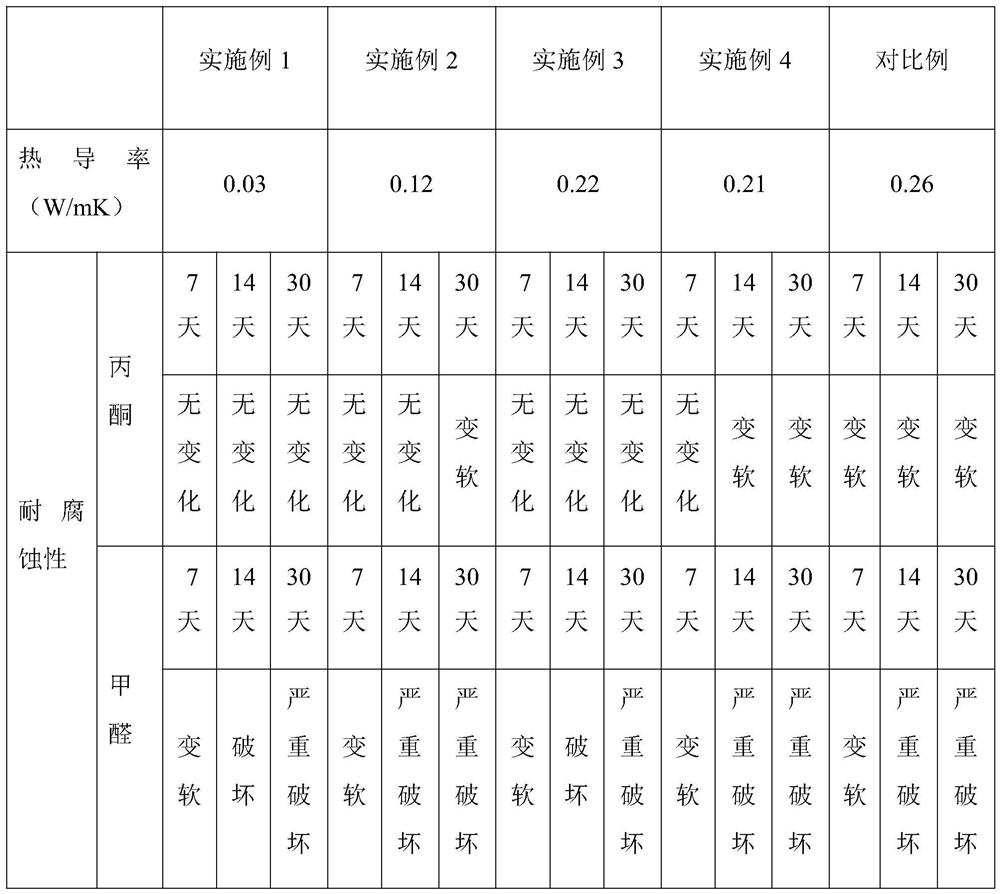

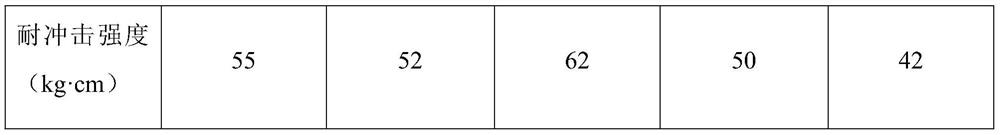

Examples

Embodiment 1

[0035] A thermal insulation and corrosion-resistant powder coating, in parts by weight, mainly comprising: 55 parts of epoxy resin E-44, 3 parts of m-phenylenediamine, 1 part of organic silicon leveling agent, and 1 part of silane coupling agent KH- 550 and 40 parts insulation filler.

[0036] A preparation method of a thermal insulation and corrosion-resistant powder coating, the preparation method of the thermal insulation and corrosion-resistant powder coating mainly comprises the following preparation steps:

[0037] (1) Mix dopamine and water in a beaker at a mass ratio of 1:10, add tris hydrochloride with 1.2 times the mass of dopamine to the beaker, and add 0.8 times the mass of dopamine to the beaker The nano-zinc powder was treated, stirred and reacted for 18 hours at a temperature of 25 °C, and then filtered to obtain a modified nano-zinc powder blank. After drying for 3h under the conditions of , the modified nano-zinc powder was obtained;

[0038] (2) potassium t...

Embodiment 2

[0045] A thermal insulation and corrosion-resistant powder coating, in parts by weight, mainly comprising: 55 parts of epoxy resin E-44, 3 parts of m-phenylenediamine, 1 part of organic silicon leveling agent, and 1 part of silane coupling agent KH- 550 and 40 parts insulation filler.

[0046] A preparation method of a thermal insulation and corrosion-resistant powder coating, the preparation method of the thermal insulation and corrosion-resistant powder coating mainly comprises the following preparation steps:

[0047] (1) the hydrochloric acid that potassium tetratitanate and concentration are 2mol / L are mixed by mass ratio 1:12, after stirring reaction 72h under room temperature conditions, change acid solution every 24 hours, filter, obtain tetratitanate blank, After washing the tetratitanic acid blank with deionized water for 8 times, it is dried to constant weight at a temperature of 80 ° C to obtain tetratitanic acid. The ratio of 1:15 was mixed in the flask, and afte...

Embodiment 3

[0053] A thermal insulation and corrosion-resistant powder coating, in parts by weight, mainly comprising: 55 parts of epoxy resin E-44, 3 parts of m-phenylenediamine, 1 part of organic silicon leveling agent, and 1 part of silane coupling agent KH- 550 and 40 parts insulation filler.

[0054] A preparation method of a thermal insulation and corrosion-resistant powder coating, the preparation method of the thermal insulation and corrosion-resistant powder coating mainly comprises the following preparation steps:

[0055] (1) Mix dopamine and water in a beaker at a mass ratio of 1:10, add tris hydrochloride with 1.2 times the mass of dopamine to the beaker, and add 0.8 times the mass of dopamine to the beaker The nano-zinc powder was treated, stirred and reacted for 18 hours at a temperature of 25 °C, and then filtered to obtain a modified nano-zinc powder blank. After drying for 3h under the conditions of , the modified nano-zinc powder was obtained;

[0056] (2) potassium t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com