Engine lubricating oil and preparation method thereof

A technology for lubricating oil and engine, applied in the field of lubricating oil, can solve the problem of oxidation resistance, high temperature resistance, wear resistance, poor sealing performance, oil cleanliness, dispersibility and wear resistance damage, piston ring and cylinder liner corrosion and other problems, to achieve the effect of reducing friction coefficient, good high temperature deposit formation, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

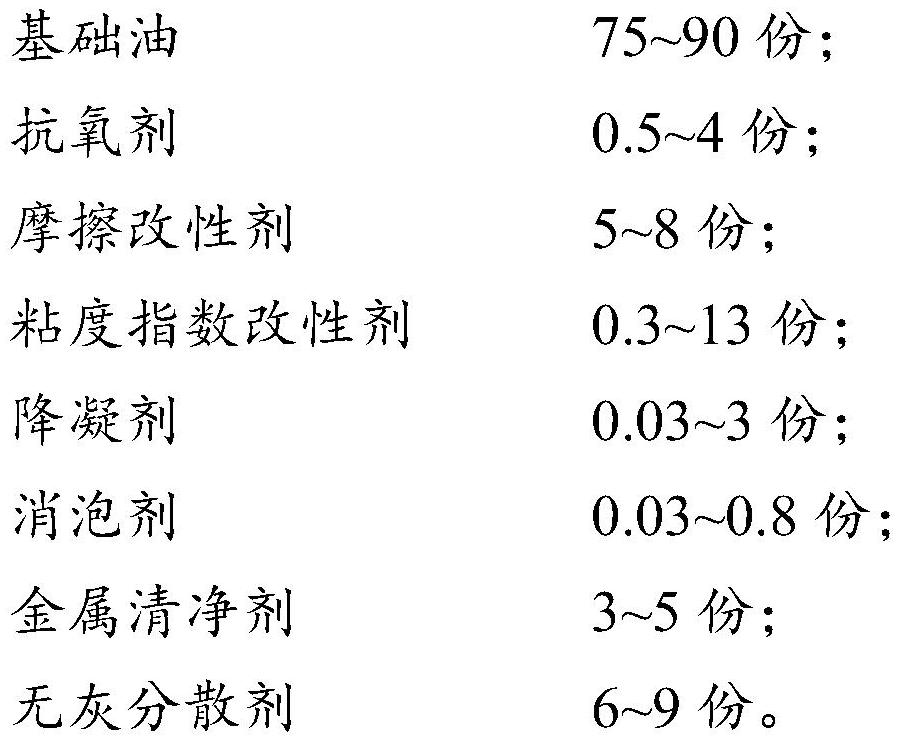

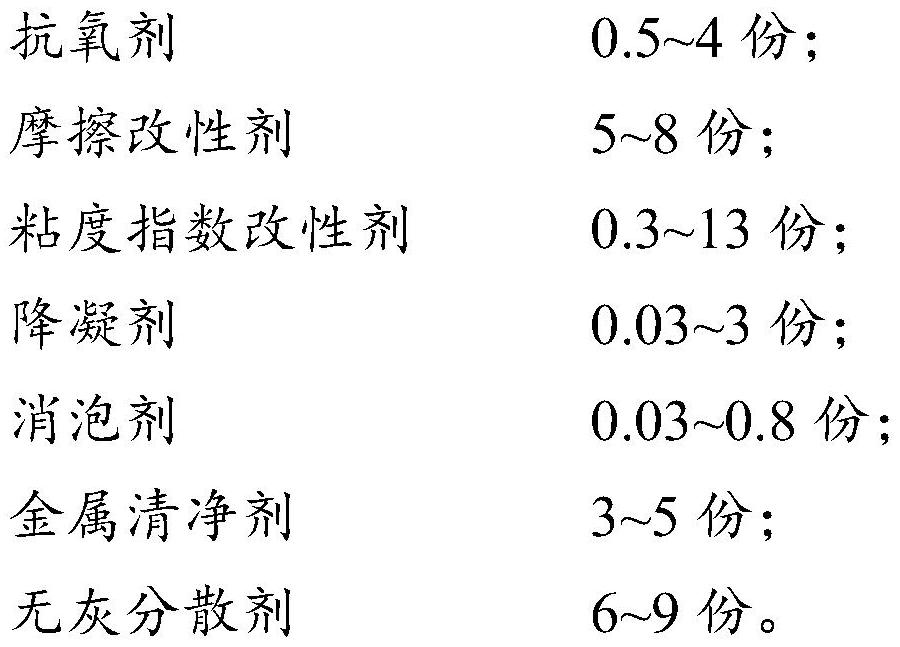

Method used

Image

Examples

preparation example Construction

[0048] The present invention also provides a kind of preparation method of described engine lubricating oil, comprises the following steps:

[0049] 1) mixing base oil, antioxidant and pour point depressant to obtain the first mixture;

[0050] 2) mixing the first mixture, the friction modifier, the viscosity index modifier and the ashless dispersant to obtain a second mixture;

[0051] 3) Mixing the second mixture, the defoamer and the metal detergent to obtain the engine lubricating oil.

[0052] The mixing temperature in step 1) of the present invention is preferably 40-50°C, more preferably 42-47°C, more preferably 44-45°C; the mixing time is preferably 1-2h, more preferably 1.5h; Step 2) the mixing temperature is preferably 45-55°C, more preferably 48-52°C, more preferably 50°C; the mixing time is preferably 0.5-1.5h, more preferably 1h; step 3) The mixing temperature is preferably 60-70°C, more preferably 63-68°C, more preferably 65-66°C; the mixing time is preferably ...

Embodiment 1

[0057] 75kg base oil (in the base oil, PAO6, PAO10 and pentaerythritol ester are 30kg, 35kg, 10kg respectively), 0.3kg n-butyl, 2-ethylhexyl zinc dithiophosphate, 0.2kg n-butyl, 4-ethyl Add 2-hexyl zinc dithiophosphate and 0.03kg polyalphaolefin into the reaction kettle, and mix for 2 hours at 40°C and 1000r / min. Then add 5kg molybdenum dialkyldithiophosphate, 0.3kg polymethacrylate, 3kg polyisobutylene monosuccinimide, 3kg polyisobutylene bisuccinimide (polyisobutylene monosuccinimide and polyisobutylene monosuccinimide) The number-average molecular weight of the polyisobutylene part of isobutylene bis-succinimide is 1500), and mixed at 45°C and 1000r / min for 1.5h. Finally, 0.03 kg of silicone oil and 3 kg of sulfurized calcium alkylphenate were added and mixed for 1 hour at 60° C. at a speed of 1000 r / min to obtain engine lubricating oil.

[0058] The engine lubricating oil of Example 1 has a phosphorus content of 0.075wt%, a sulfur content of 0.25wt%, a sulfate ash content...

Embodiment 2

[0060] 90kg base oil (in the base oil, PAO6, PAO10 and pentaerythritol ester are 35kg, 40kg, 15kg respectively), 2kg tert-butyl diphenylamine, 2kg2,2'-thiobis[3-(3,5-di-tert-butyl Base-4-hydroxyphenyl) ethyl propionate] and 3kg polymethacrylate were added into the reaction kettle, and mixed at 50°C and 2000r / min for 1h. Then add 4kg molybdenum xanthate, 4kg molybdate, 13kg styrene-isoprene copolymer, 9kg polyisobutylene bis-succinimide (the number average molecular weight of the polyisobutylene part is 4000), at 55 ℃, 2000r / min speed of mixing for 0.5h. Finally, 0.8 kg of polydimethylsiloxane, 2.5 kg of overbased magnesium sulfonate and 2.5 kg of overbased magnesium sulfonate were added, and mixed for 0.5 h at 70° C. at a speed of 2000 r / min to obtain engine lubricating oil.

[0061] The engine lubricating oil of Example 2 has a phosphorus content of 0.07wt%, a sulfur content of 0.2wt%, a sulfate ash content of 0.75wt%, a nitrogen content of 0.08wt%, and a base value of 9.5m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com