A kind of polyhydroxy functionalized ionic liquid lubricant and preparation method thereof

A technology for ionic liquids and lubricants, applied in chemical instruments and methods, lubricating compositions, hydrotalcites, etc., to achieve the effects of strong practicability, reduced wear, and superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Add magnesium nitrate hexahydrate, aluminum nitrate nonahydrate and urotropine into water to obtain a mixed solution, wherein the concentrations of magnesium nitrate hexahydrate, aluminum nitrate nonahydrate and urotropine are 0.032mol / L and 0.016mol respectively / L, 0.042mol / L;

[0035] 2) Transfer the mixed solution of step 1) to a hydrothermal kettle, heat in a vacuum box at 150°C for 30 hours, then cool to room temperature at 25°C, take out the suspension, filter it, and wash with ethanol reagent;

[0036] 3) The slurry after step 2) was first dispersed in an acetone solvent with a solid-to-liquid ratio of 1 wt%, and after the slurry was collected by centrifugation, it was again dispersed in cyclohexane reagent with a solid-to-liquid ratio of 1 wt% to obtain a colloidal solution;

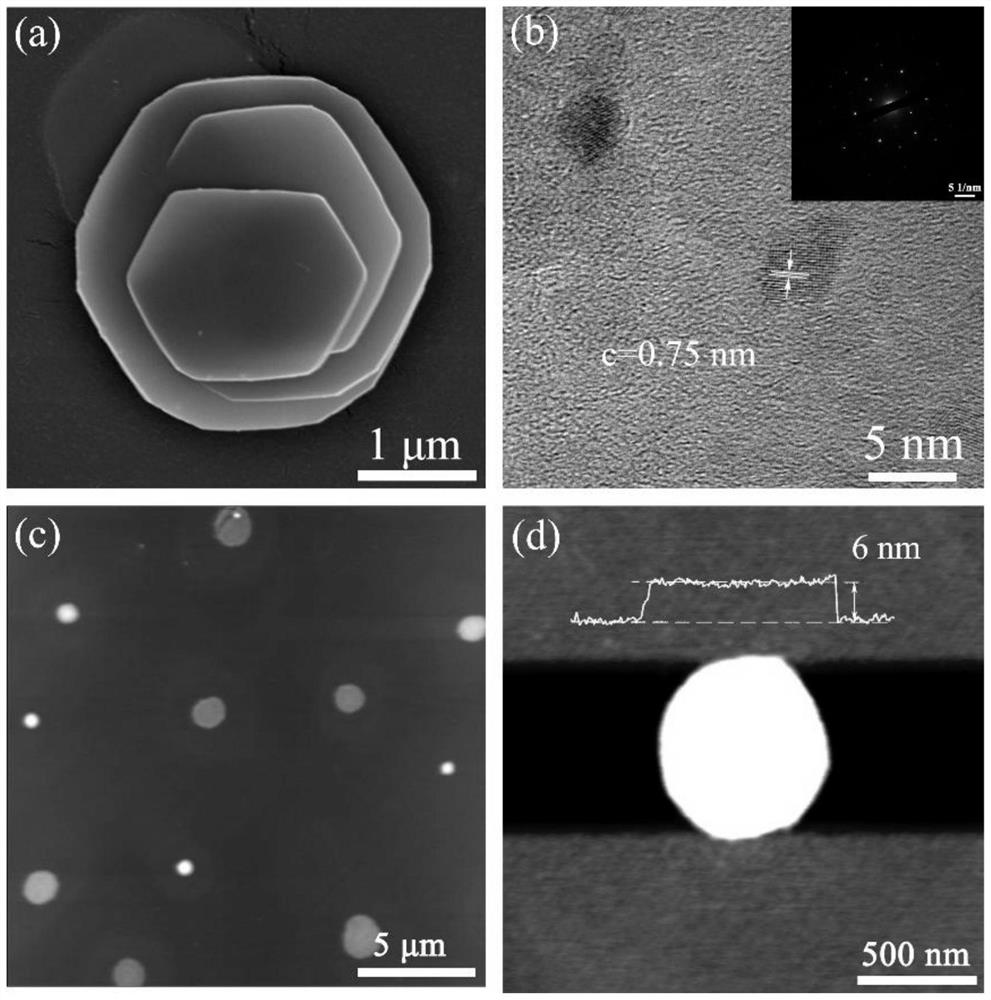

[0037] 4) Place the colloidal solution in step 3) in a freeze-drying device for 24 hours to obtain the following: figure 1 (a) Hydrotalcite nanosheets (1500-3000nm in lateral dimensio...

Embodiment 2

[0040] 1) Disperse the ionic liquid of 1-butyl-2,3-dimethylimidazolium tetrafluoroborate in the proportion of 5wt% in the ethylene glycol organic reagent to obtain the ionic liquid lubricant.

[0041] 2) Add the hydrotalcite nanosheets prepared in Example 1 as an additive to the ionic liquid lubricant at a mass fraction of 1 wt%, and stir and disperse to obtain a polyhydroxy functionalized ionic liquid lubricant.

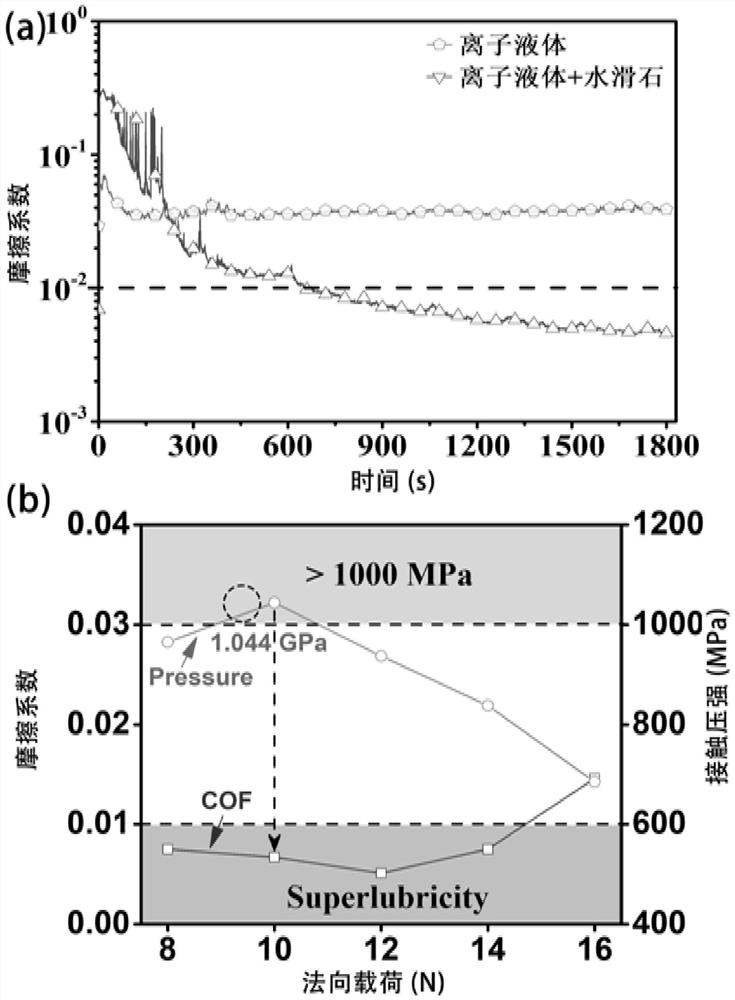

[0042] The lubricant prepared above was tested using the ball-on-disk reciprocating mode of the UMT5 friction and wear testing machine. The friction sample is composed of a silicon nitride ball and a sapphire sheet (the elastic modulus and Poisson's ratio of silicon nitride are 300GPa and 0.27 respectively, and the elastic modulus and Poisson's ratio of sapphire are 340GPa and 0.25 respectively), and the indoor ambient humidity is 30 %, the diameter of the upper sample is 14mm. The friction test was carried out under a load with a frictional force of 12N and a slid...

Embodiment 3

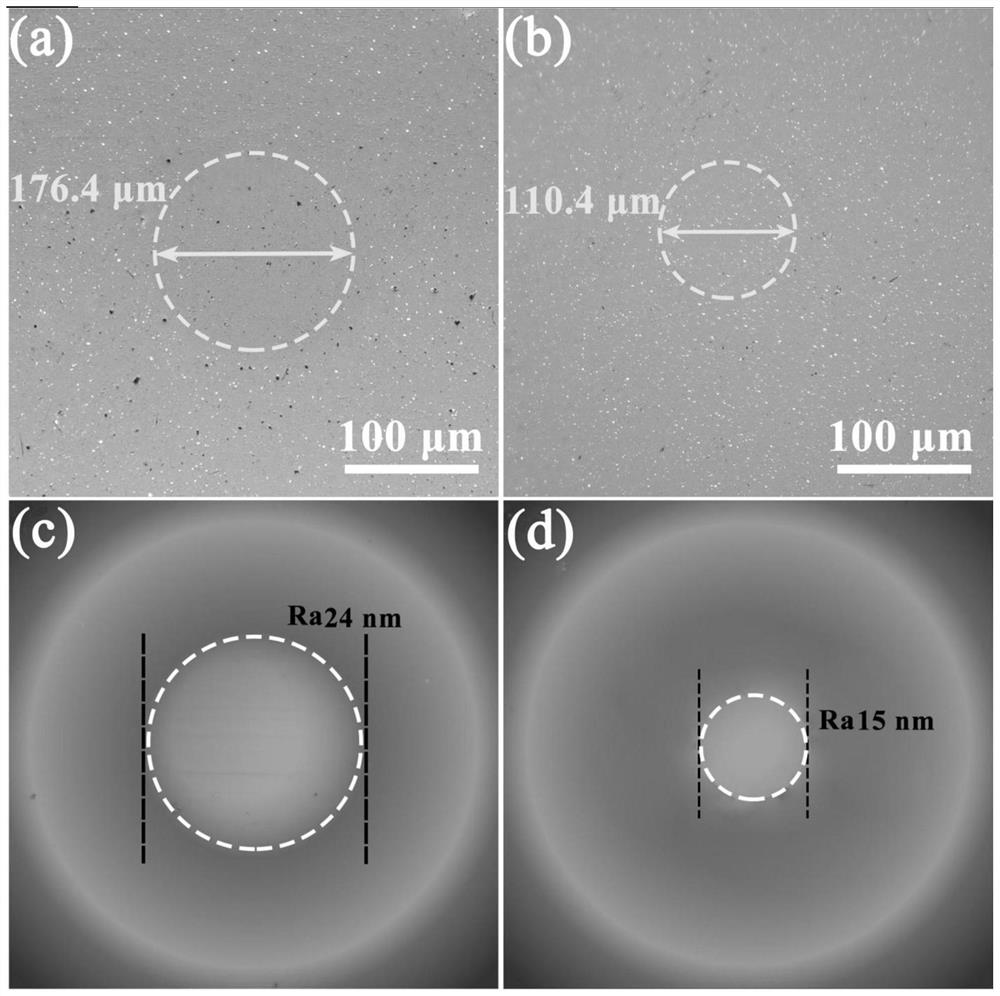

[0045] The physical morphology and structural changes of the contact surface will directly affect the superlubrication behavior under high contact pressure, so it is necessary to further study the wear degree of the friction pair of the lubricant with hydrotalcite nanosheets as an additive and pure ionic liquid. Under the same test conditions as in Example 2, the degree of wear formed by the frictional silicon nitride balls was observed through an optical microscope and a three-dimensional white light interferometer.

[0046] Compared with pure ionic liquid lubricants, the friction pairs of lubricants containing hydrotalcite nanosheets (with a thickness of 1 nm to 10 nm) have the smallest wear diameter, such as image 3 (b) The diameter shown in (b) is 110.4 μm, and the wear surface of the friction pair is relatively smooth, with a few cracks and small wear pits ( image 3 The surface roughness shown in (d) is 15 nm. Such as image 3 (a) and image 3 As shown in (c), non-dire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com