Carbon nanosheet composite material as well as preparation method and application thereof

A technology of composite materials and carbon nanosheets, applied in chemical instruments and methods, other chemical processes, alkali metal compounds, etc., can solve the problems of limiting the catalytic ability of persulfate, reducing the exposure of active sites, etc., and achieve recyclability Good, the effect of improving charge transfer efficiency and high electron transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

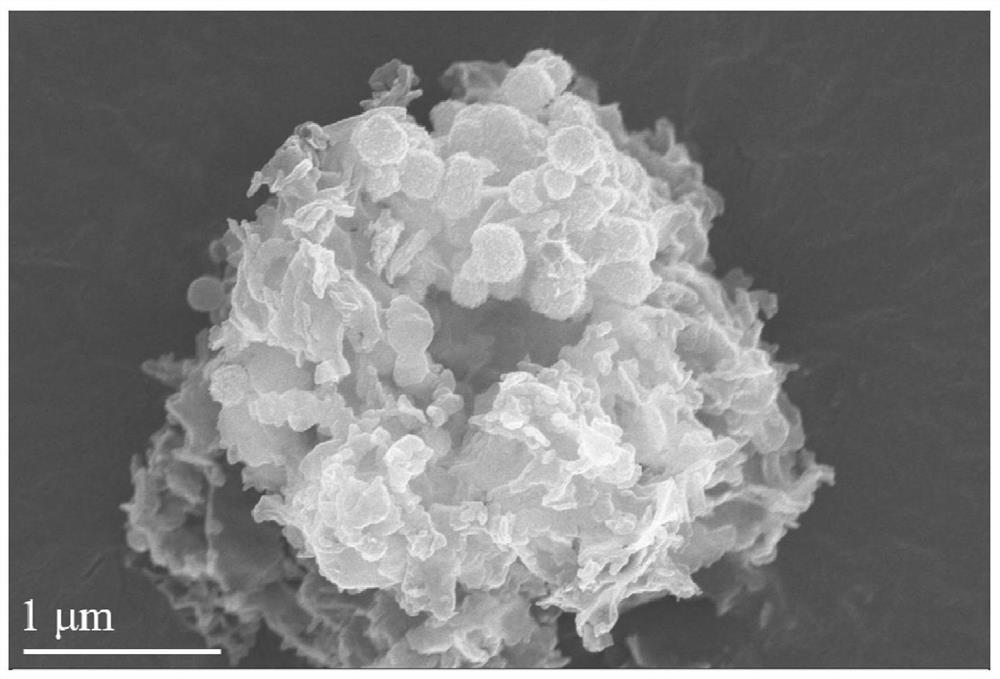

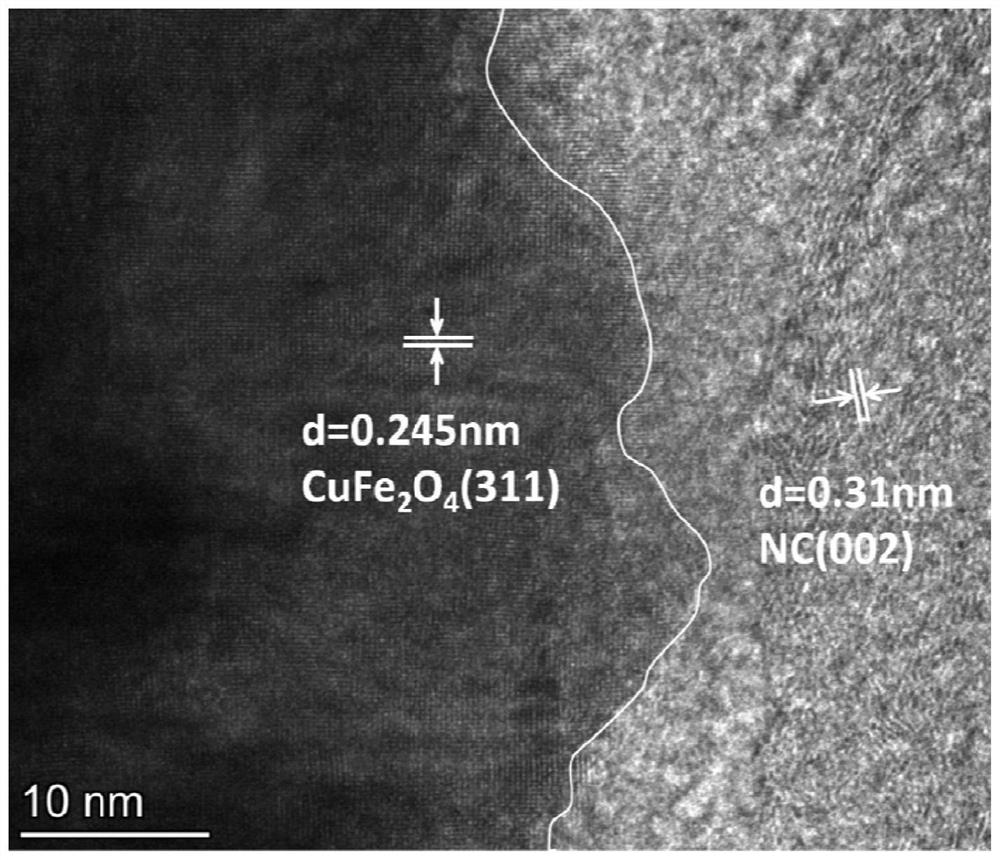

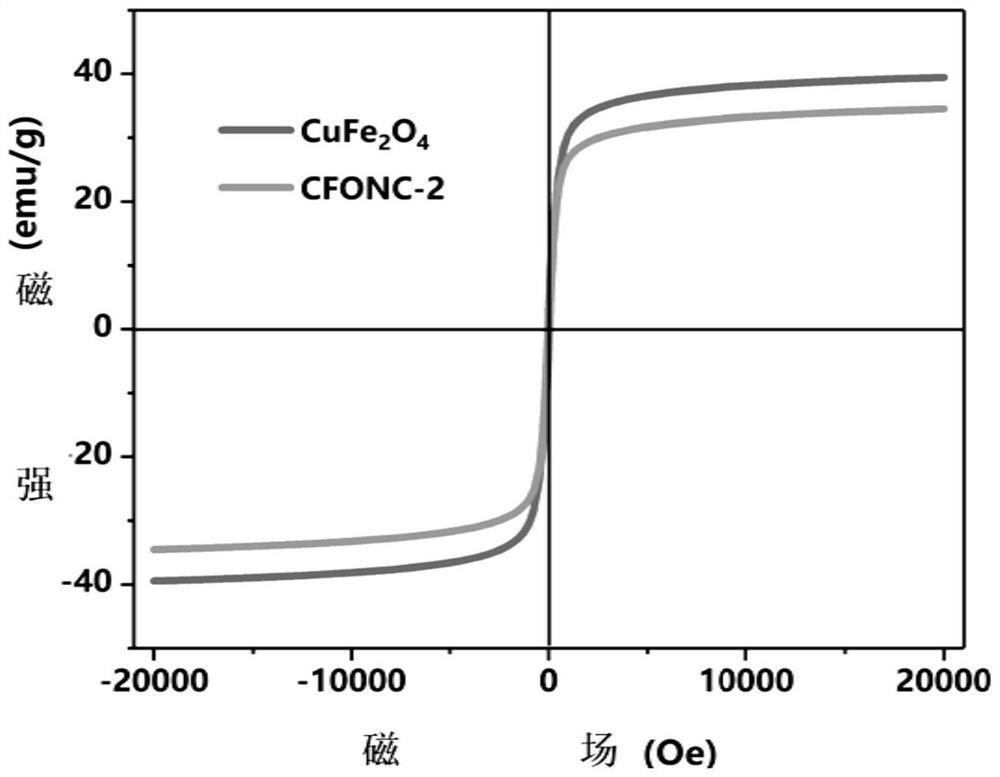

[0061] In this example, a carbon nanosheet composite material is prepared. The composite material is composed of copper ferrite nanoparticles and nitrogen-doped carbon nanosheets. The composite material has a spherical-sheet three-dimensional structure. The mass ratio is 30%.

[0062] The preparation method specifically includes the following steps:

[0063] (1) 10 g of urea was weighed and put into a covered crucible with a diameter of 50 mm, and calcined at 500° C. for 4 h to obtain flake graphite phase carbon nitride. Subsequently, 2 g of graphitic carbon nitride and 0.5 g of glucose were weighed into 60 ml of deionized water, and subjected to ultrasonic treatment for 4 h. The obtained mixed suspension was placed in a 100 ml reactor for 12 h at 180 °C and cooled to room temperature. Filtration and drying, the obtained solid was calcined at 900 °C for 1 h under nitrogen atmosphere to obtain nitrogen-doped carbon nanosheets NC;

Embodiment 2

[0067] In this example, a carbon nanosheet composite material is prepared. The composite material is composed of copper ferrite nanoparticles and nitrogen-doped carbon nanosheets. The composite material has a spherical-sheet three-dimensional structure. The mass ratio is 40%.

[0068] The preparation method specifically includes the following steps:

[0069] (1) 10 g of urea was weighed and put into a covered crucible with a diameter of 50 mm, and calcined at 500° C. for 4 h to obtain flake graphite phase carbon nitride. Subsequently, 2 g of graphitic carbon nitride and 0.5 g of glucose were weighed into 60 ml of deionized water, and subjected to ultrasonic treatment for 4 h. The obtained mixed suspension was placed in a 100 ml reactor for 12 h at 180 °C and cooled to room temperature. Filtration and drying, the obtained solid was calcined at 900 °C for 1 h under nitrogen atmosphere to obtain nitrogen-doped carbon nanosheets NC;

[0070] (2) 1mmol copper nitrate hexahydrate ...

Embodiment 3

[0075] In this example, a carbon nanosheet composite material is prepared. The composite material is composed of copper ferrite nanoparticles and nitrogen-doped carbon nanosheets. The composite material has a spherical-sheet three-dimensional structure. The mass ratio is 50%.

[0076] The preparation method specifically includes the following steps:

[0077] (1) 10 g of urea was weighed and put into a covered crucible with a diameter of 50 mm, and calcined at 500° C. for 4 h to obtain flake graphite phase carbon nitride. Subsequently, 2 g of graphitic carbon nitride and 0.5 g of glucose were weighed into 60 ml of deionized water, and subjected to ultrasonic treatment for 4 hours. Filtration and drying, the obtained solid was calcined at 900 °C for 1 h under nitrogen atmosphere to obtain nitrogen-doped carbon nanosheets NC;

[0078] (2) 1mmol hexahydrate copper nitrate and 2mmol nonahydrate ferric nitrate are added in 35mL ethylene glycol, stirring 30min under rotating speed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com