Sulfur/selenium bridge asphalt porous polymer and preparation method thereof

A technology of porous polymers and asphalt, which is applied in the direction of separation methods, chemical instruments and methods, and other chemical processes, can solve problems such as difficult to obtain high-value utilization, unutilized waste, and low efficiency of waste utilization, and achieve the goal of preparation process Environmental protection, low price and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

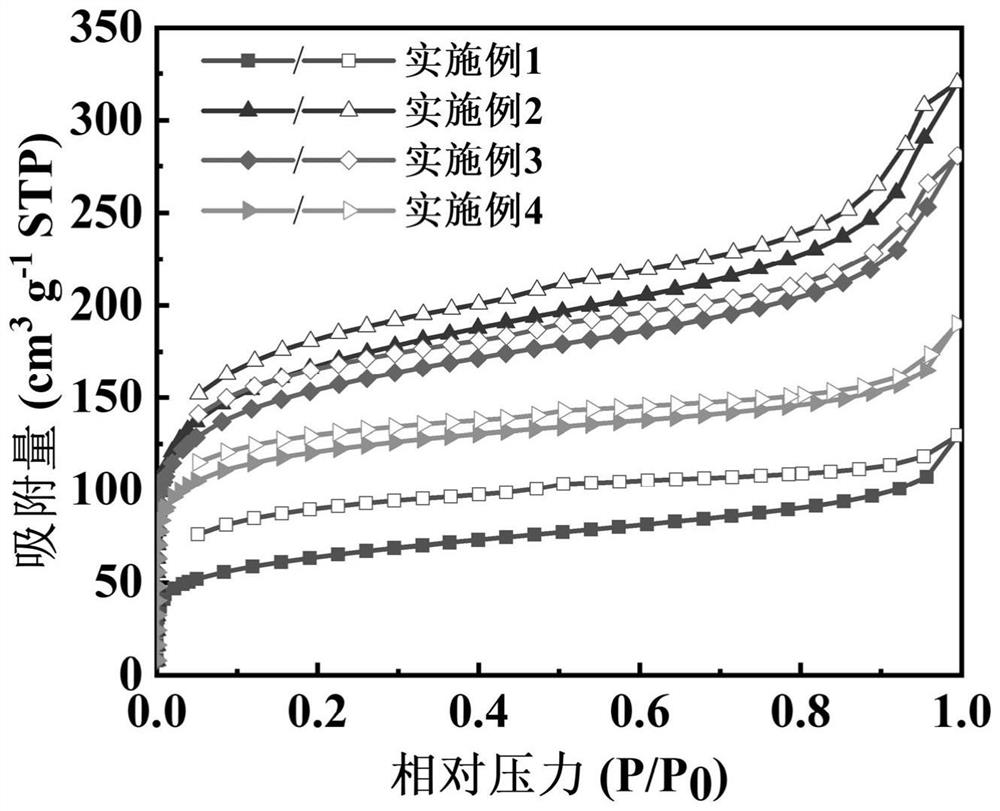

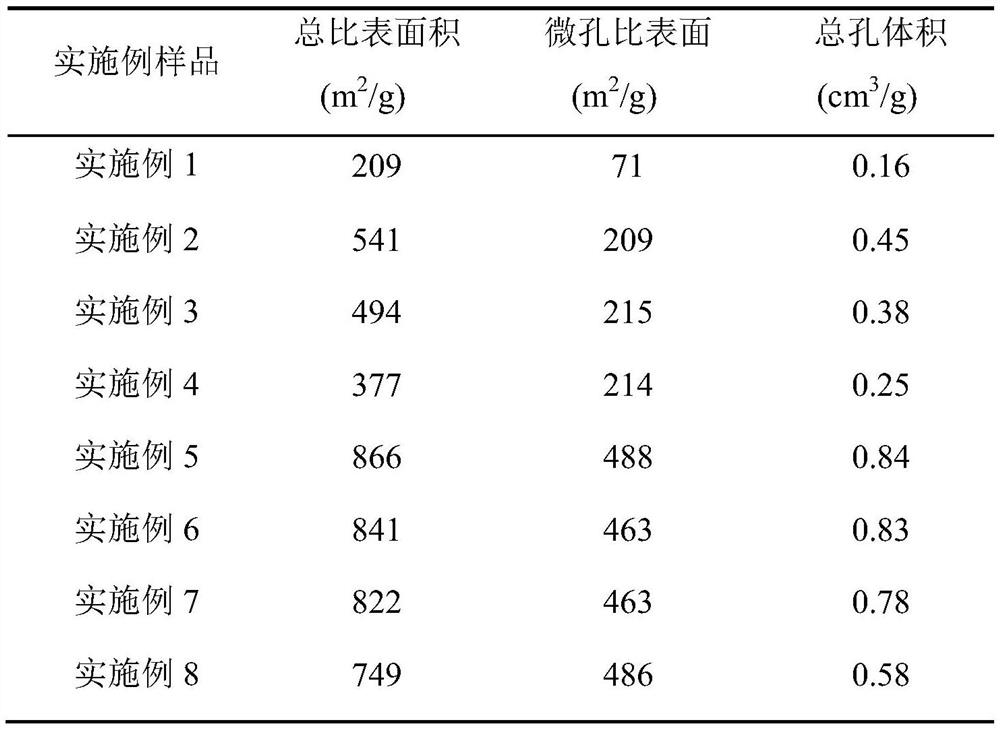

[0026] The preparation specific surface area is 209m 2 / g, the pore volume is 0.16cm 3 / g of sulfur-bridged asphalt porous polymer.

[0027] The present embodiment adopts following formula:

[0028] Asphalt: 0.18g

[0029] Elemental sulfur: 0.02g

[0030] Diphenylsulfone: 0.40g

[0031] Prepare sulfur bridge asphalt porous polymer with above-mentioned formula composition according to following method:

[0032] 1. Add a certain amount of bitumen, elemental sulfur and diphenyl sulfone into a mortar, mix well, grind thoroughly, transfer to a glass test tube with a narrow neck, and seal the glass test tube under vacuum.

[0033] 2. Put the sealed glass tube containing the reaction materials described in step 1 in a self-made salt bath, react at 300°C for 5 hours, and continue to react for 5 hours after raising the temperature to 350°C. After the reaction, the glass tube was taken out and cooled to room temperature naturally.

[0034] 3. The reaction mixture in step 2 was se...

Embodiment 2

[0036]The preparation specific surface area is 541m 2 / g, the pore volume is 0.45cm 3 / g of sulfur-bridged asphalt porous polymer.

[0037] The present embodiment adopts following formula:

[0038] Asphalt: 0.16g

[0039] Elemental sulfur: 0.04g

[0040] Diphenylsulfone: 0.40g

[0041] Prepare sulfur bridge asphalt porous polymer with above-mentioned formula composition according to following method:

[0042] 1. Add a certain amount of bitumen, elemental sulfur and diphenyl sulfone into a mortar, mix well, grind thoroughly, transfer to a glass test tube with a narrow neck, and seal the glass test tube under vacuum.

[0043] 2. Put the sealed glass tube containing the reaction materials described in step 1 in a self-made salt bath, react at 300°C for 5 hours, and continue to react for 5 hours after raising the temperature to 350°C. After the reaction, the glass tube was taken out and cooled to room temperature naturally.

[0044] 3. The reaction mixture in step 2 was seq...

Embodiment 3

[0046] The preparation specific surface area is 494m 2 / g, the pore volume is 0.38cm 3 / g of sulfur-bridged asphalt porous polymer.

[0047] The present embodiment adopts following formula:

[0048] Asphalt: 0.14g

[0049] Elemental sulfur: 0.06g

[0050] Diphenylsulfone: 0.40g

[0051] Prepare sulfur bridge asphalt porous polymer with above-mentioned formula composition according to following method:

[0052] 1. Add a certain amount of bitumen, elemental sulfur and diphenyl sulfone into a mortar, mix well, grind thoroughly, transfer to a glass test tube with a narrow neck, and seal the glass test tube under vacuum.

[0053] 2. Put the sealed glass tube containing the reaction materials described in step 1 in a self-made salt bath, react at 300°C for 5 hours, and continue to react for 5 hours after raising the temperature to 350°C. After the reaction, the glass tube was taken out and cooled to room temperature naturally.

[0054] 3. The reaction mixture in step 2 was se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com