Preparation method of coral reef-shaped TiO2 (C) material, product and application of coral reef-shaped TiO2 (C) material

A coral reef and raw material technology, applied in the field of photocatalytic material preparation, can solve the problems of wastewater treatment separation and recovery difficulties, low catalytic activity, doping, etc., and achieve the effects of green development, uniform products, and high photocatalytic removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

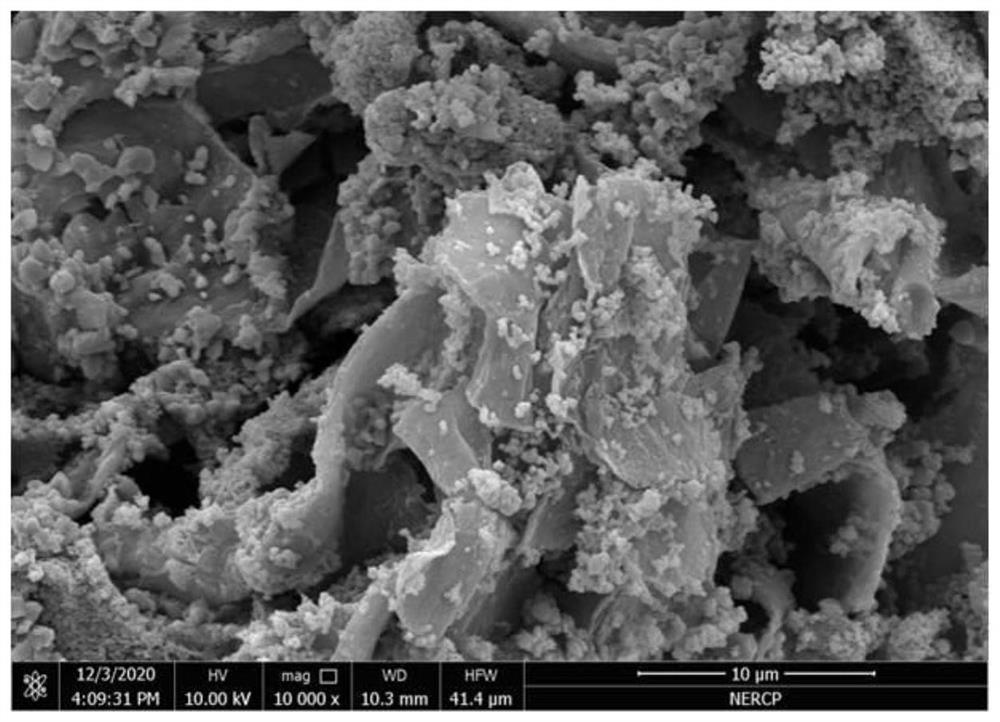

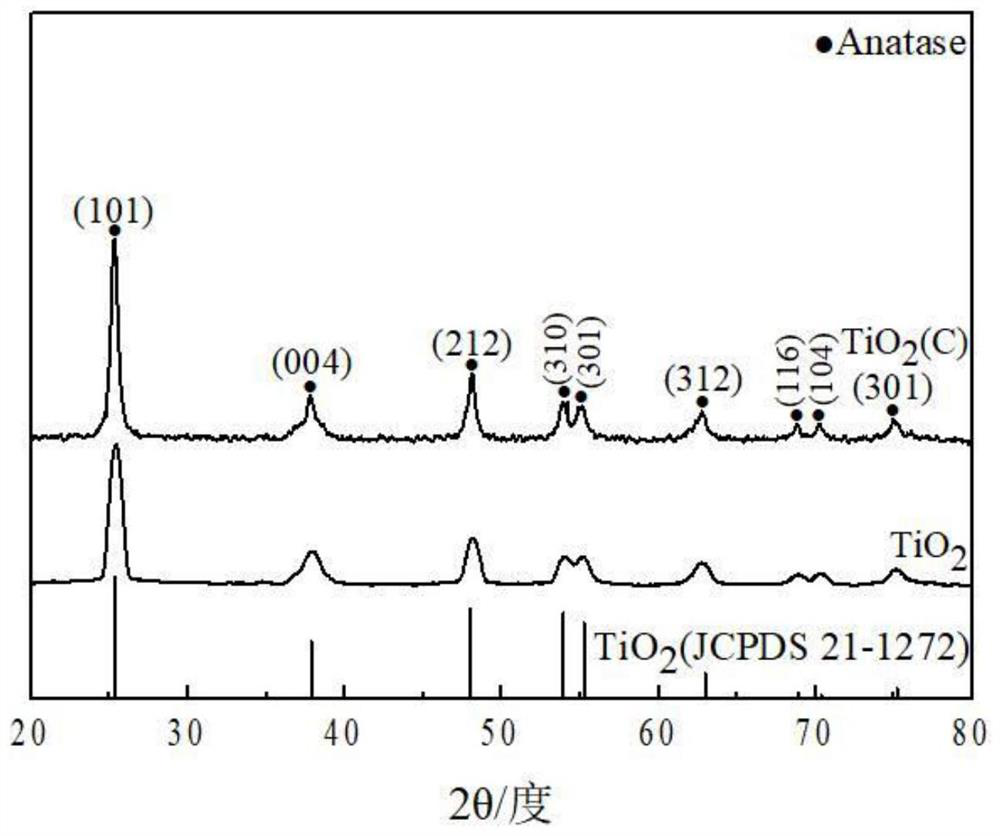

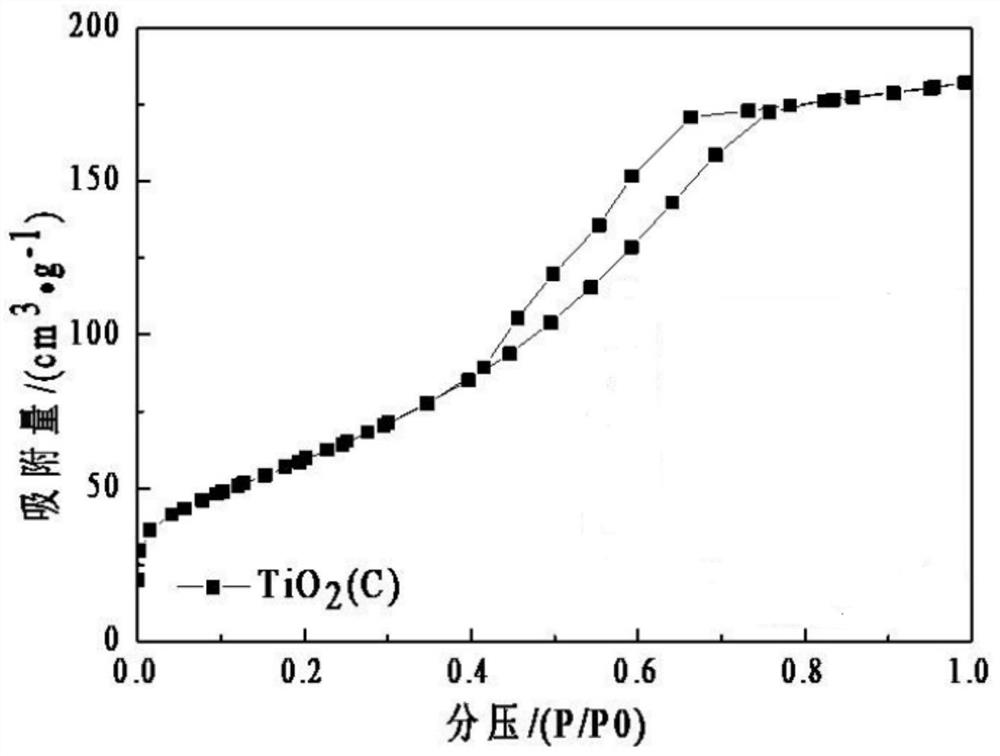

[0036] This embodiment provides a coral reef-like TiO for photocatalytic degradation of tetracycline 2 (C) Preparation method of material:

[0037] (1) After crushing the raw material corn stalks to 20 mesh, wash them three times with deionized water and ethanol respectively, and dry them in a vacuum oven at 60°C for 48 hours to obtain dry clean corn stalks;

[0038] (2) Carbonize clean corn stalks under the protection of N2 in an atmosphere tube furnace, N2 filling rate: 100mL / min, heating rate: 8°C / min, carbonization temperature: 500°C, carbonization time: 7h, and different Homemade corn stalk biochar at low temperature;

[0039] (3) Weigh 1.0±0.01g of the self-made corn stalk biochar and add it to 8mL of absolute ethanol solution, stir the mixed solution at 500r / min for 30min, slowly add 4 mL of tetraisopropoxy Titanium, continue to stir for 2h to obtain solution A;

[0040] (4) 4 mL of glacial acetic acid and 4 mL of absolute ethanol were mixed evenly with 500 r / min mag...

Embodiment 2

[0047] The coral reef shape TiO that embodiment 1 makes 2 (C) Material photocatalytic degradation of tetracycline (TC), including the following steps:

[0048] (1) pipette 100mL initial concentration is the tetracycline solution of 25ppm, add the coral reef shape TiO obtained in embodiment 1 2 (C) Material, coral reef-like TiO 2 (C) The amount of material used is 0.15g, and it is stirred at 500r / min for 30min in the dark at room temperature;

[0049] (2) After the photocatalytic reaction (ultraviolet light power is 7W) in the photocatalytic reactor for 2h, the coral reef-like TiO 2 (C) The material is separated from the solution, and the absorbance of the tetracycline solution is measured at 350 nm with a spectrophotometer, and the calculated degradation rate reaches 83%.

[0050] Among the present invention, the calculation method of degradation rate is: according to the calculation formula of degradation rate: D=[(A 0 -A t ) / A 0 ]× 100%, where: A 0 is the initial abso...

Embodiment 3

[0052] (1) Under the conditions of Example 2, explore the impact of the initial concentration of tetracycline solution on the catalytic effect, the specific steps are as follows:

[0053] Pipette 100mL initial concentration to be the tetracycline solution of 10,15,20,25,30ppm, add the coral reef shape TiO that obtains in embodiment 1 2 (C) Material, coral reef-like TiO 2 (C) The amount of material used is 0.15g, and it is stirred at room temperature for 30 minutes in the dark, and then the photocatalytic reaction is carried out in a photocatalytic reactor. After 2 hours, the coral reef-like TiO 2 (C) The material is separated from the solution, and the absorbance of the tetracycline solution is measured at 350nm with a spectrophotometer, and the degradation rate is calculated as shown in Table 1:

[0054] Table 1 Coral reef-like TiO 2 (C) Degradation rate of materials to different tetracycline concentrations

[0055]

[0056] It can be seen from Table 1 that the coral re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com