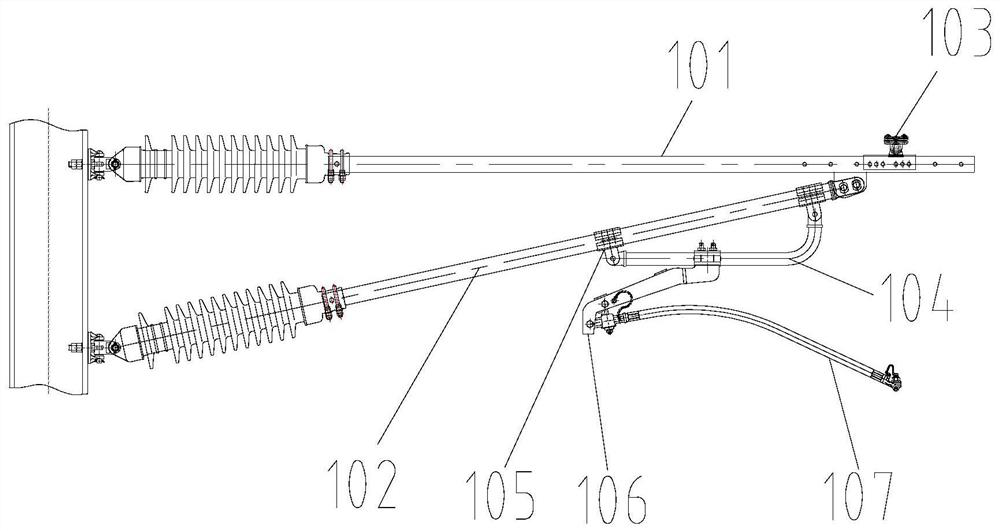

Overhead line system steel cantilever positioning device coated with dirt-repellent composite coating and machining method

A composite coating, positioning device technology, applied in the direction of coating, anti-corrosion coating, conductive coating, etc., can solve the problem of no coating technology and products, affecting the conductive performance of catenary

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

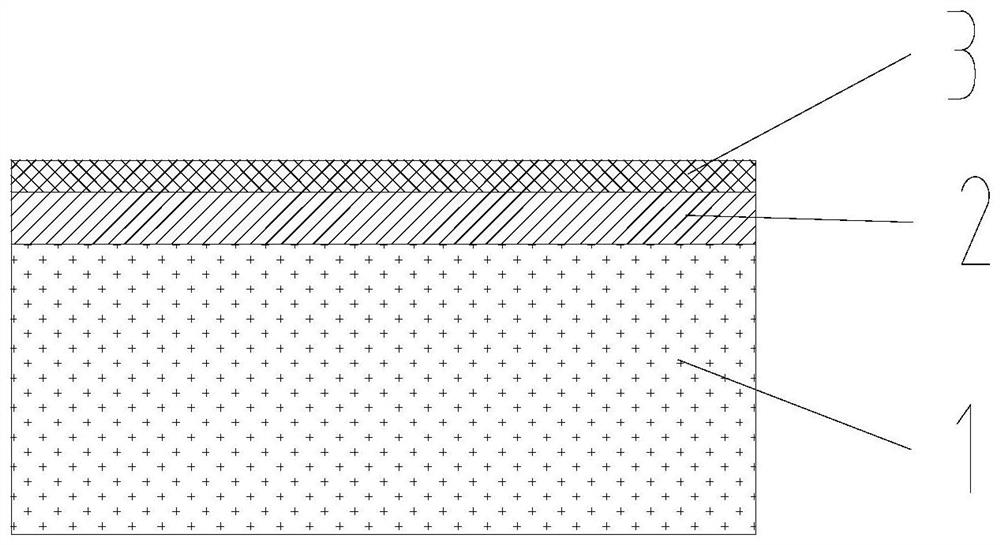

[0072] Formula components by mass, take by weighing 10 parts of film-forming resin (organosilicon modified bisphenol A epoxy resin SM-60), 55 parts of organosilicon monomer (methyltriethoxysilane), crosslinking agent ( Tetraethyl silicate) 0.5 parts, interface adhesive (aminopropyltriethoxysilane) 5 parts, catalyst (dibutyltin dilaurate) 0.1 part, conductive filler (1 μm flake aluminum powder) 30 parts, 1 part of corrosion inhibitor and passivation agent (sodium molybdate), 0.2 part of orientation agent (polyvinylpyrrolidone), 3-6 parts of dustproof agent (organic bentonite), 10 parts of solvent (6 parts of ethanol, 4 parts of propylene glycol methyl ether) 0.3 part, 0.3 part of defoamer (Defom 8700), 5 parts of pigment and filler (iron oxide red), after mixing and stirring evenly, grind in a sand mill until the fineness is about 25 μm, that is, to obtain the contact net assembly Anti-corrosion conductive and foul-repellent coating.

Embodiment 2

[0074] Formula components by mass, weigh 20 parts of film-forming resin (organosilicon modified bisphenol A epoxy resin SM-60), silicone monomer (40 parts of methyltriethoxysilane, methyltrichlorosilane 25 parts) 65 parts, crosslinking agent (methyl orthosilicate) 2.5 parts, interface adhesive (aminopropyltriethoxysilane) 10 parts, catalyst (organobismuth catalyst) 0.3 parts, conductive filler (1μm sheet aluminum powder) 60 parts, corrosion inhibitor passivation agent (cerium nitrate) 3 parts, orientation agent (polyvinylpyrrolidone) 0.4 parts, dustproof agent (organic bentonite) 6 parts, solvent (12 parts ethanol, propylene glycol methyl ether 8 parts) 20 parts, 0.8 parts of defoamer (Defom 8700), 20 parts of pigments and fillers (red iron oxide), after mixing and stirring evenly, grind in a sand mill until the fineness is about 25 μm, that is, the described Corrosion-resistant, conductive, and foul-repellent coatings for catenary components.

Embodiment 3

[0076] Formula components by mass, weigh 15 parts of film-forming resin (organosilicon modified bisphenol A epoxy resin SM-60), silicone monomer (40 parts of methyl triethoxysilane, dimethyl dichloride 15 parts of silane) 55 parts, 1.5 parts of crosslinking agent (tetraethyl orthosilicate), 8 parts of interface adhesive (aminopropyltriethoxysilane), 0.2 parts of catalyst (dibutyltin dilaurate), conductive 50 parts of filler (1μm flake aluminum powder), 2 parts of corrosion inhibitor and passivation agent (cerium nitrate), 0.3 parts of orientation agent (polyvinylpyrrolidone), 4 parts of dustproof agent (organic bentonite), solvent (8 parts of ethanol , 7 parts of propylene glycol methyl ether) 15 parts, defoamer (Defom 8700) 0.6 part, pigment and filler (iron oxide red) 15 parts, after mixing and stirring evenly, grind in a sand mill until the fineness is about 25 μm, that is The anti-corrosion conductive dirt-repellent paint for the catenary assembly is obtained.

[0077] In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com