Modified adsorbent for adsorption separation and preparation method and application thereof

An adsorption separation and adsorbent technology, applied in the field of modified adsorbent and its preparation, can solve the problems of cumbersome operation, long crystallization time, inconvenient wide application, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

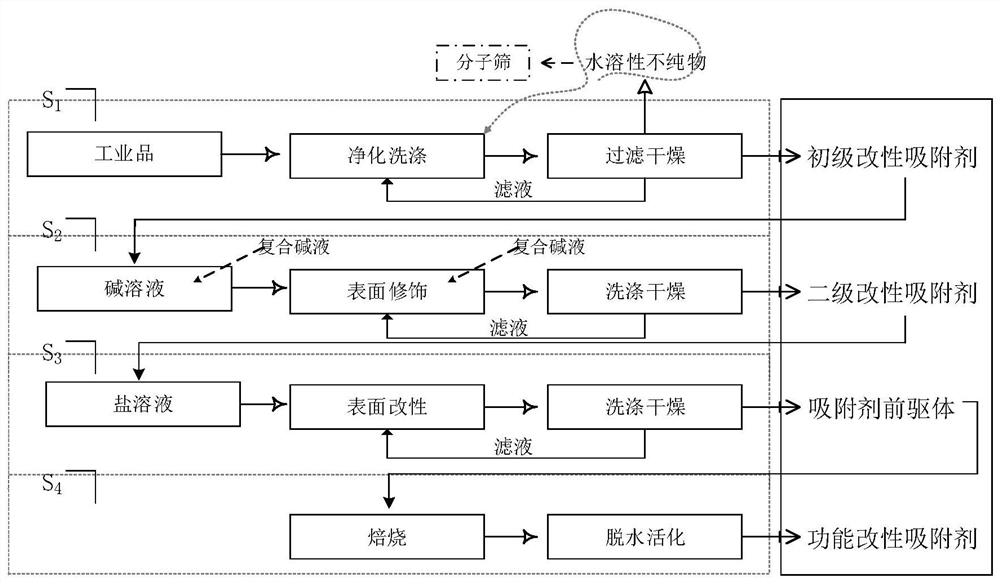

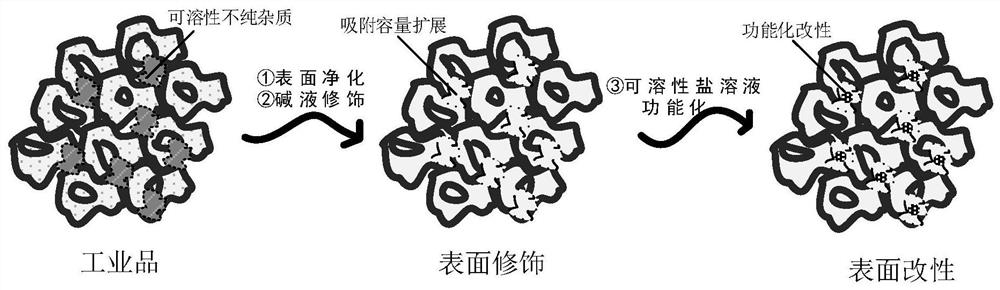

Method used

Image

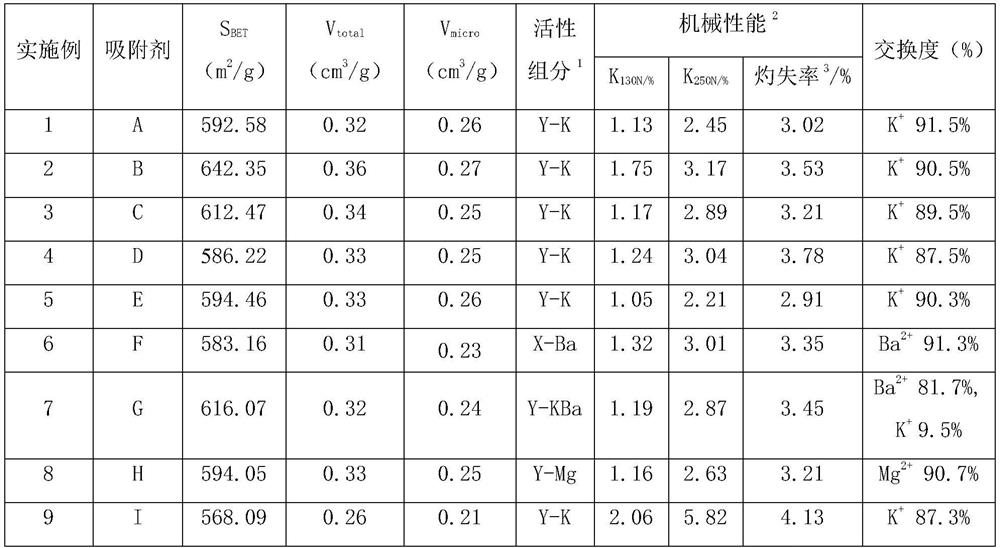

Examples

Embodiment 1

[0044] (1) Prepare the primary modified adsorbent, that is, take 5 kg of industrial NaY molecular sieve particles (0.3-0.8mm; Si / Al=4.37;) and put them into a reaction tank equipped with 50L demineralized water, stir at 80°C for 5h, and then cool down to room temperature, after natural settlement for 24-48 hours, separate the supernatant liquid to remove water-soluble impure substances, which are mainly unformed raw powder micro-slag, or soluble fine powder such as kaolin binder, which can be recycled for Molecular sieves are synthesized, and the filtrate is recovered for the next use.

[0045] (2) Configuration of composite lye 5.2SiO 2 :Al 2 o 3 :3.2Na 2 O:220H 2 O, the composite alkaline solution can be used first and configured first, or it can be sealed and stored for several days before use. The above alkaline solution is mixed and contacted with the primary modified adsorbent. The temperature is maintained at 100 °C for 4 hours, and the filtrate is recovered. For t...

Embodiment 2

[0049] Repeat the preparation method among the embodiment 1, change the composite lye described in the embodiment 1 step (2) into concentration and be 1.1mol / L NaOH, use with water glass compatibility, silicon content is 1.8wt% in the composite lye , maintaining a liquid-solid mass ratio of 1.3:1; at a temperature of 95°C and a treatment time of 5 hours, the functionally modified adsorbent B was obtained.

Embodiment 3

[0051] Repeat the preparation method in Example 1, change the composite lye described in Example 1 step (2) into a concentration of 1.6mol / L NaOH, do not add others, and maintain a liquid-solid ratio of 1.4:1; at a temperature of 90°C , the treatment time was 2 h, and the functionally modified adsorbent C was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com