Chemical sewage treatment process based on PSF-g-CS polymer microfiltration membrane

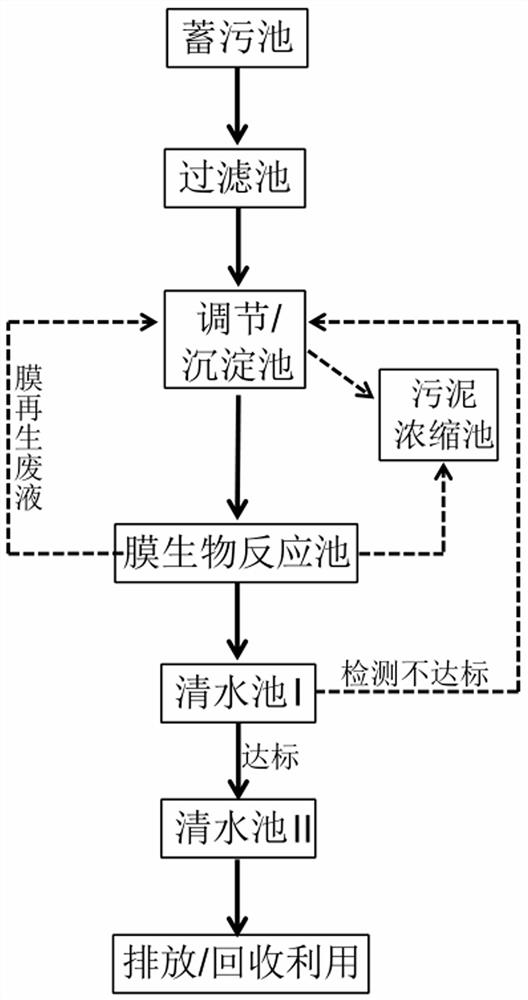

A sewage treatment method and polymer technology, applied in biological water/sewage treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the waste of valuable materials, short membrane service life, and late start of membrane technology and other problems, to achieve the effect of long service life, improved hydrophilic performance, and improved anti-ultraviolet performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

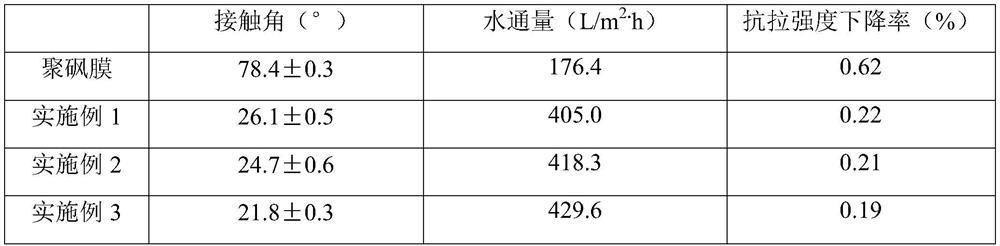

Examples

Embodiment 1

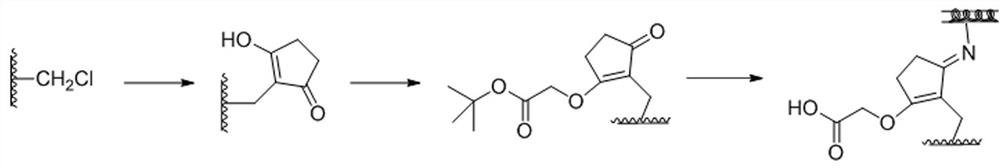

[0044] A preparation method of PSF-g-CS polymer microfiltration membrane, comprising the following steps:

[0045] S1. Chloromethylation of polysulfone: Dissolve polysulfone (Mw35000) in dichloromethane, stir to dissolve completely, then add paraformaldehyde and trimethylchlorosilane, polysulfone and paraformaldehyde, trimethyl chloride The mass volume ratio of silane and tin tetrachloride is 40g:30g:90mL:2mL, stir evenly and slowly add tin tetrachloride solution under stirring state, react at 35°C for 60h to obtain chloromethylated polysulfone;

[0046] S2. Preparation of hydroxycycloketene polysulfone: Dissolve 1,3-cyclopentadione in 1M aqueous sodium hydroxide solution, then add chloromethylated polysulfone to the mixture, 1,3-cyclopentadione The mass ratio of ketone to chloromethylated polysulfone is 3:10, and the mixture is heated to 75°C for 8 hours to obtain hydroxycycloketene polysulfone;

[0047] S3. Alkylation reaction of hydroxycycloketene polysulfone: dissolve hyd...

Embodiment 2

[0052] A preparation method of PSF-g-CS polymer microfiltration membrane, comprising the following steps:

[0053] S1. Chloromethylation of polysulfone: Dissolve polysulfone (Mw35000) in dichloromethane, stir to dissolve completely, then add paraformaldehyde and trimethylchlorosilane, polysulfone and paraformaldehyde, trimethyl chloride The mass volume ratio of silane and tin tetrachloride is 45g:35g:95mL:2mL, stir evenly and slowly add tin tetrachloride solution under stirring state, react at 35°C for 60h to obtain chloromethylated polysulfone;

[0054] S2. Preparation of hydroxycycloketene polysulfone: Dissolve 5-methylcyclohexane-1,3-dione in 1M aqueous sodium hydroxide solution, then add chloromethylated polysulfone to the mixture, 5 - The mass ratio of methylcyclohexane-1,3-dione to chloromethylated polysulfone is 2:5, and the mixture is heated to 80°C for 9 hours to obtain hydroxycycloketene polysulfone;

[0055] S3. Alkylation reaction of hydroxycycloketene polysulfone...

Embodiment 3

[0060] A preparation method of PSF-g-CS polymer microfiltration membrane, comprising the following steps:

[0061] S1. Chloromethylation of polysulfone: Dissolve polysulfone (Mw35000) in dichloromethane, stir to dissolve completely, then add paraformaldehyde and trimethylchlorosilane, polysulfone and paraformaldehyde, trimethyl chloride The mass volume ratio of silane and tin tetrachloride is 50g:40g:100mL:3mL, stir evenly and slowly add tin tetrachloride solution under stirring state, react at 35°C for 70h to obtain chloromethylated polysulfone;

[0062] S2. Preparation of hydroxycycloketene polysulfone: Dissolve 5-(2-thienyl)cyclohexane-1,3-dione in 1M aqueous sodium hydroxide solution, then add chloromethylated polysulfone to mix In the liquid, the mass ratio of 5-(2-thienyl)cyclohexane-1,3-dione to chloromethylated polysulfone is 1:2, and the mixture is heated to 90°C for 10 hours to obtain hydroxycycloketene polysulfone One of sulfone; phenyl) cyclohexane-1,3-dione;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com