A method for preparing magnesium-zinc-yttrium quasicrystals and titanium carbide synergistically strengthened magnesium-based composites

A composite material, magnesium-zinc-yttrium technology, applied in the direction of manufacturing tools, casting molding equipment, metal processing equipment, etc., can solve the problem of limited strengthening effect of the reinforcement, and achieve the effect of accurate and detailed data, advanced technology and strict process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

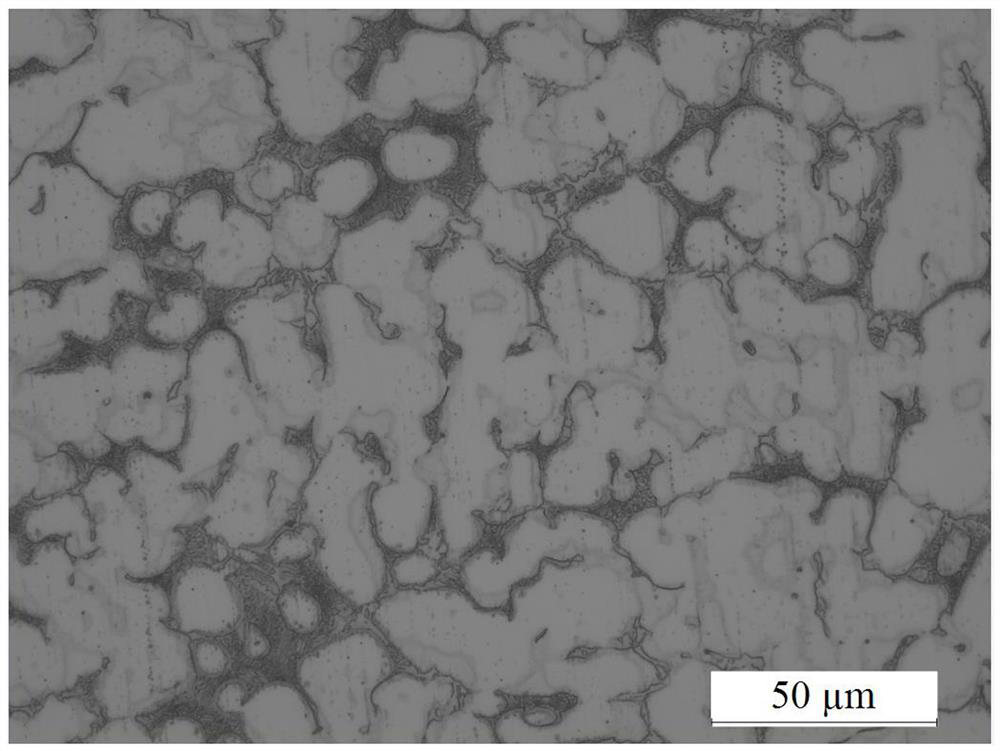

Image

Examples

Embodiment Construction

[0054] A method for preparing a magnesium-zinc-yttrium quasicrystal and titanium carbide synergistically strengthened magnesium-based composite materials, the chemical materials used are: zinc oxide, talcum powder, water glass, deionized water, aluminum foil, absolute ethanol, argon, aluminum Powder, titanium powder, multi-walled carbon nanotubes, magnesium-zinc-yttrium-zirconium master alloy, the combined preparation dosage is as follows: take gram, milliliter, cubic centimeter as the measurement unit

[0056] Talc: Mg 3 [Si 4 o 10 ](OH) 2 55g±1g

[0057] Water glass: Na 2 SiO 3 •9H 2 O 25g±1g

[0058] Deionized water: H 2 O 1000mL±50mL

[0059] Aluminum foil: Al 300mm×0.5mm×300mm

[0060] Absolute ethanol: C 2 h 5 OH 3500mL±50mL

[0061] Argon: Ar 800000cm 3 ±100cm 3

[0062] Aluminum powder: Al 22g±1g

[0063] Titanium powder: Ti 50g±1g

[0064] Multi-walled carbon nanotubes 13g±0.1g

[0065] Magnesium zinc yttrium zirconiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com