Chemical method for promoting silver nanowire nodes to be welded into continuous low-resistance conductive network

A nano-silver wire, conductive network technology, applied in nanotechnology, nanotechnology, liquid chemical plating and other directions, can solve the problems of large contact resistance and contact stability, damage, limited resistance reduction, etc., to increase the bonding strength. and overlap area, increase the contact area, reduce the effect of contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

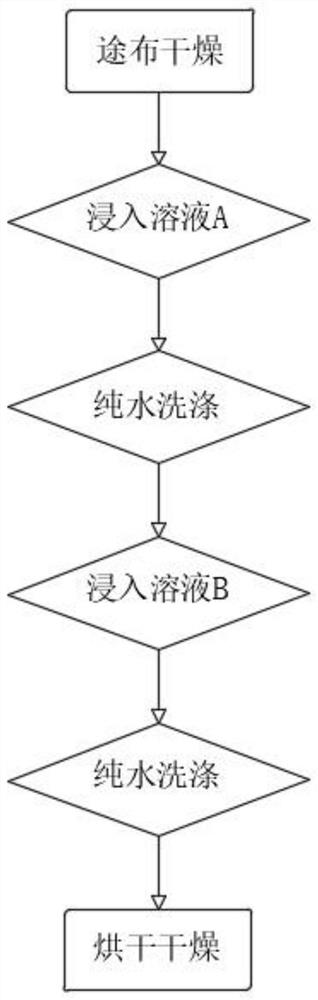

[0049] see figure 2 , the flexible transparent PET film (thickness 125 μm) that is coated with nano silver wire is immersed in the silver ammonia solution containing 30mM glucose, silver source concentration 35mM, immersion time 2min; After cleaning the conductive film with pure water, place the flexible transparent PET film coated with nano-silver wire in a drying device for drying, and the drying stability should not exceed 110°C, which ensures the drying of the flexible transparent PET film coated with nano-silver wire security at the time.

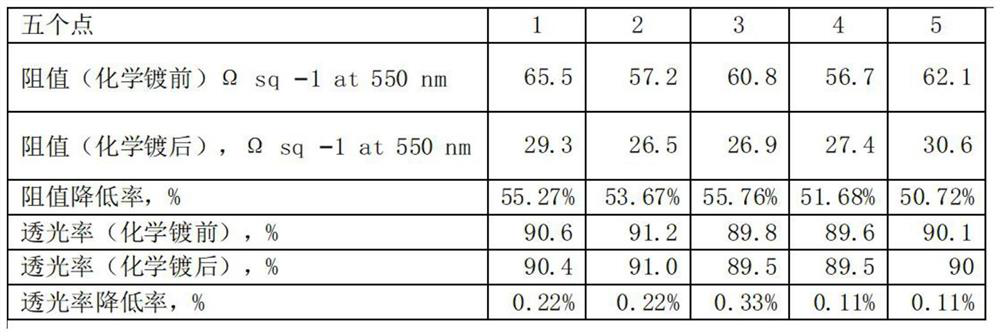

[0050] After the drying is completed, take 5 points, use a four-corner probe to detect the resistance value and light transmittance of each point before and after electroless plating treatment, and list the data changes before and after treatment as follows figure 1 .

Embodiment 2

[0052] see image 3 , the flexible transparent PEN film (thickness 200 μ m) that is coated with nano-silver wire is immersed in the silver ammonia solution containing 50mM ascorbic acid, the concentration of silver source is 50mM, and soaking time is 3min; Clean the conductive film with pure water, and then place the flexible transparent PET film coated with nano-silver wire in a drying device for drying, and the drying stability should not exceed 110°C, ensuring that the flexible transparent PET film coated with nano-silver wire is dry security.

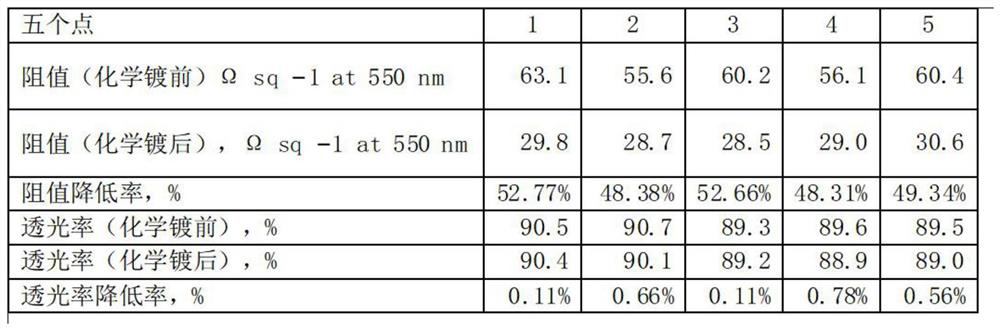

[0053] Take 5 points, use a four-corner probe to detect the resistance value and light transmittance of each point before and after electroless plating treatment, and list the data changes before and after treatment as follows figure 2 :

Embodiment 3

[0055] see Figure 4 , immerse the flexible transparent PI film (thickness 100 μm) coated with nano-silver wire in the silver ammonia solution containing 60mM isoascorbic acid, the silver source concentration is 45mM, and the soaking time is 4min; after washing with pure water, immerse in 150mM NaF aqueous solution for 8 minutes , clean the conductive film with pure water, and then place the flexible transparent PET film coated with nano-silver wire in a drying device for drying, and the drying stability should not exceed 110°C, which ensures the drying of the flexible transparent PET film coated with nano-silver wire security at the time.

[0056] Take 5 points, use a four-corner probe to detect the resistance value and light transmittance of each point before and after electroless plating treatment, and list the data changes before and after treatment as follows image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com