Isomerization catalyst and preparation method thereof

A catalyst and isomerization technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, organic isomerization, etc., can solve the problem of unfavorable long-term stable operation of catalysts, unfavorable industrial production and application, and influence on the crystal structure of molecular sieves, etc. problems, to achieve long-term stable operation, improve reaction efficiency and isomerization selectivity, and prevent carbon deposition and deactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1. Preparation of modified alumina

[0044] Take 1000 grams of pseudo-boehmite and place it in a beaker, add a solution (about 1000 mL) prepared by 37.6 grams of magnesium nitrate to it for equal volume impregnation, after aging at room temperature for 24 hours, dry at 100 ° C for 12 hours to obtain Modified alumina.

[0045] 2. Preparation of sodium molecular sieve

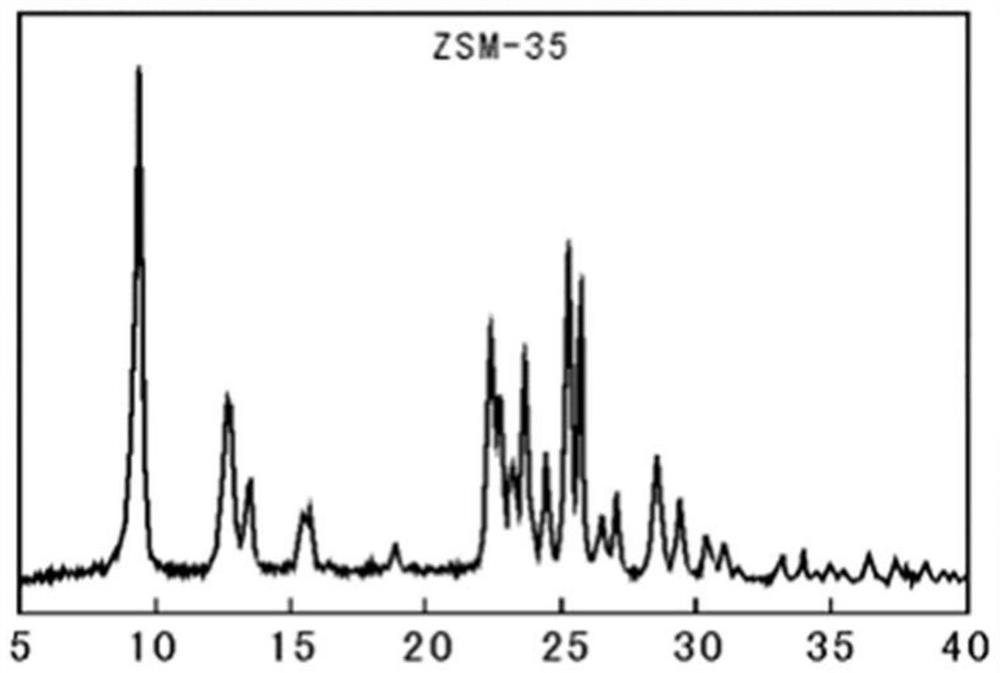

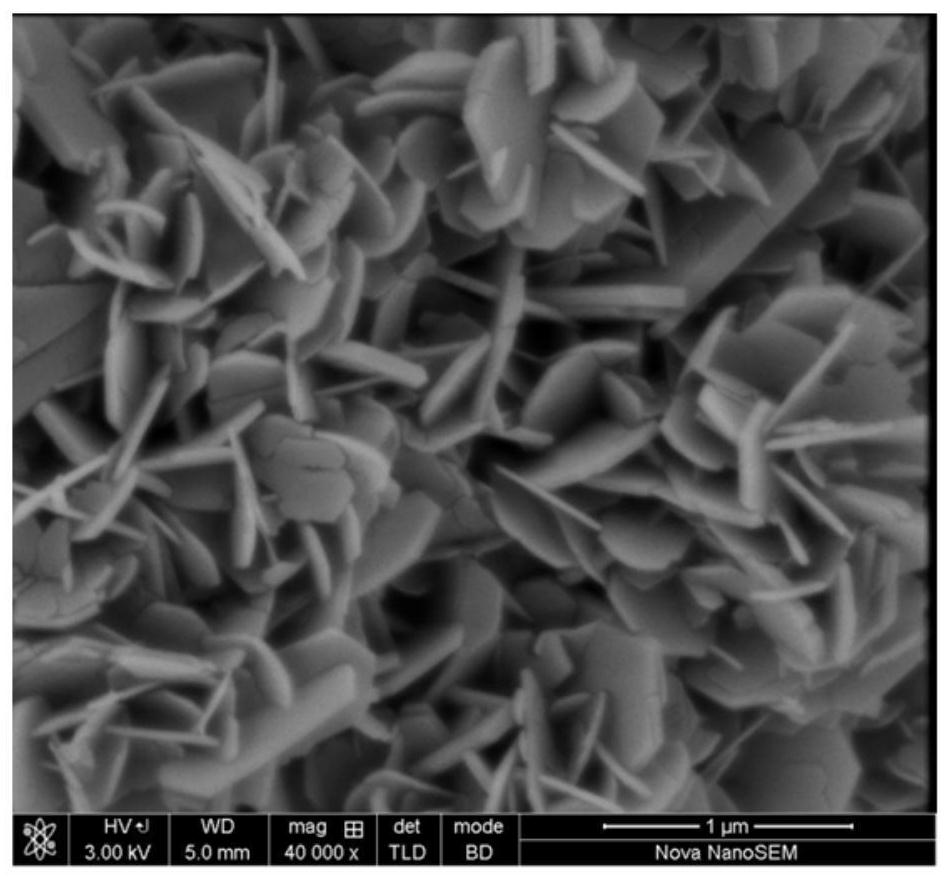

[0046] According to 1Al 2 o 3 : 29.6SiO2 2 : 7 cyclohexylamine: 600H 2 The feed ratio (molar ratio) of O, under stirring conditions, 4000 grams of deionized water, 293 grams of sodium hydroxide, and silica sol, sodium aluminate and cyclohexylamine according to the metering ratio are added in the autoclave, after stirring , synthesized by crystallization at 145°C for 72 hours; after the crystallization synthesis, the filtrate of the crystallization synthesis product was washed with deionized water to neutrality, and the filter cake was dried to obtain Na-type ZSM-35 molecular sieve, such as figure 1 w...

Embodiment 2

[0052] 1. Preparation of modified alumina

[0053] Take 1000 grams of pseudo-boehmite and place it in a beaker, add a solution (about 1000 mL) prepared by 52.8 grams of magnesium nitrate and 21.5 grams of potassium nitrate to it for equal volume impregnation, after aging at room temperature for 24 hours, dry at 100 ° C for 12 Hours, modified alumina was prepared.

[0054] 2. Preparation of sodium molecular sieve

[0055] According to 1Al 2 o 3 : 31.2SiO2 2 : 7.2 Ethylenediamine: 620H 2 The feed ratio (molar ratio) of O, under stirring condition, 4000 grams of deionized water, 293 grams of sodium hydroxide and silica sol, aluminum sulfate and ethylenediamine in metering ratio are added in the autoclave, after stirring, Crystallization synthesis at 165°C for 72 hours; after the crystallization synthesis, the filtrate of the crystallization synthesis product was washed with deionized water until neutral, and the filter cake was dried to obtain Na-type ZSM-35 molecular sieve....

Embodiment 3

[0060] 1. Preparation of modified alumina

[0061] Take 1000 grams of SB powder and place it in a beaker, add a solution (about 1000 mL) prepared by 54.4 grams of magnesium acetate to it for equal volume impregnation, after aging at room temperature for 24 hours, dry at 100 °C for 12 hours to obtain modified oxide aluminum.

[0062]2. Preparation of sodium molecular sieve

[0063] Sodium molecular sieves were prepared according to the method in Example 1.

[0064] 3. Preparation of isomerization catalyst

[0065] Adopt above-mentioned modified alumina and sodium type molecular sieve, prepare catalyst intermediate according to the method for embodiment 1;

[0066] Immerse the above catalyst intermediate in 1000mL of ammonium nitrate solution with a concentration of 1.0mol / L, and exchange it at 80°C for 2 hours; after the exchange, filter the exchange solution, and dry the exchanged catalyst intermediate; dry the dried The catalyst intermediate was submerged again in 1000 mL...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com