Composite material, preparation method thereof and quantum dot light-emitting diode

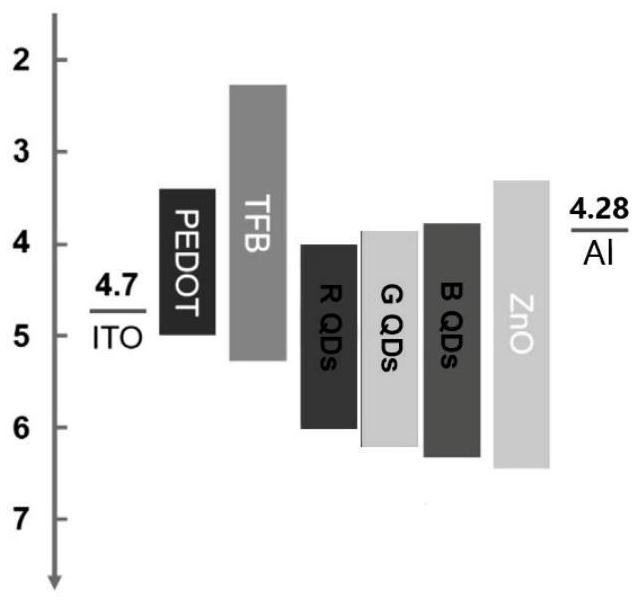

A quantum dot light-emitting and composite material technology, which is applied in the field of composite materials and its preparation, can solve the problems of quantum dot light-emitting diodes such as brightness, quantum efficiency and lifespan are not ideal, so as to improve hole transport ability, injection balance and performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

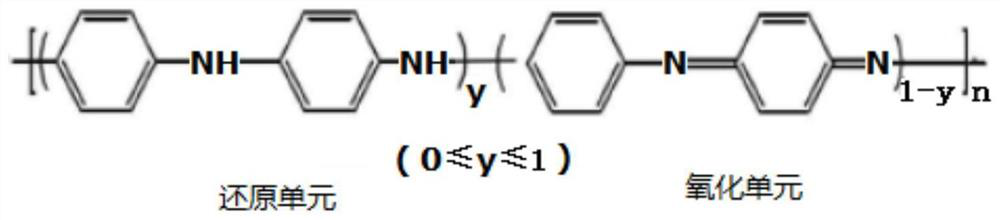

[0067] First weigh 0.2g of ammonium persulfate (NH 4 ) 2 S 2 o 8 Dissolve in 50 mL distilled water to form ammonium persulfate (NH 4 ) 2 S 2 o 8 Aqueous solution, take by weighing 3g sodium dodecylbenzenesulfonate and join in 50mL distilled water to form sodium dodecylbenzenesulfonate aqueous solution; Add 100mL hydrochloric acid solution (concentration is 0.2mol / L) and 4.0mL aniline ( An) form aniline hydrochloride solution, according to ammonium persulfate and aniline molar ratio is 0.5, add sodium dodecylbenzene sulfonate aqueous solution and drip ammonium persulfate (NH 4 ) 2 S 2 o 8 Aqueous solution, the reaction temperature is controlled at 50°C; the reaction time is 8h; finally a dark green latex is formed; 20 mL of methanol is added to the dark green latex to break the emulsion, and after vacuum filtration, wash with acetone, ethanol and distilled water until the filtrate is colorless And it is neutral, and vacuum-dried at 50°C for 24 hours to obtain dark gre...

Embodiment 2

[0069] First weigh 1.6g of ammonium persulfate (NH 4 ) 2 S 2 o 8 Dissolve in 50mL distilled water to form persulfuric acid (NH 4 ) 2 S 2 o8 Aqueous solution, take by weighing 20g sodium dodecylbenzene sulfonate and join in 50mL distilled water and form sodium dodecylbenzenesulfonate aqueous solution; Add 100mL hydrochloric acid solution (concentration is 1.4mol / L) and 4.0mL aniline ( An) form aniline hydrochloride solution; According to ammonium persulfate and aniline mol ratio is 1.5, add sodium dodecylbenzenesulfonate aqueous solution and drip ammonium persulfate (NH 4 ) 2 S 2 o 8 Aqueous solution, the reaction temperature is controlled at 60°C; the reaction time is 3h, and finally a dark green latex is formed; methanol is added to the dark green latex to break the emulsion, and after vacuum filtration, wash with acetone, ethanol and distilled water until the filtrate is colorless and It is neutral, and vacuum-dried at 50°C for 24 hours to obtain dark green polyanil...

Embodiment 3

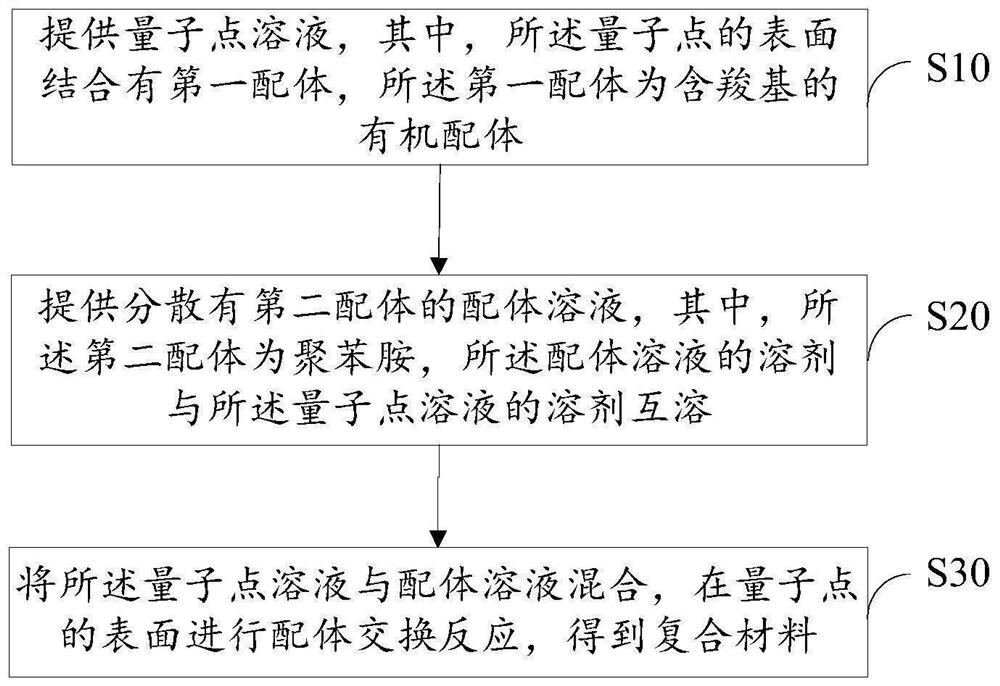

[0070] Example 3: Exchange of surface ligands

[0071] The CdZnSe / ZnS quantum dots used are synthesized in the coordination solvent oleic acid and the non-coordination solvent octadecene (ODE) system, so the surface ligands of the CdZnSe / ZnS quantum dots are oleic acid ligands. The synthesized CdZnSe / ZnS quantum dots were washed and centrifuged with a mixed solution of ethanol and n-hexane, and finally dispersed in a chloroform solution, and the concentration of CdZnSe / ZnS quantum dots was configured to be 20 mg / mL. Polyaniline was dispersed in N-methylpyrrolidone solvent, and dispersed and dissolved by an ultrasonic cleaner, and its concentration was also configured to be 20 mg / mL. After mixing the CdZnSe / ZnS quantum dot solution and the polyaniline solution uniformly at a ratio of 1:1 by volume, they were magnetically stirred at a constant temperature of 50° C. for 1 h until the ligand exchange on the surface was completed. Quantum dots with polyaniline surface ligands were...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com